Обработка с ЧПУ is at the heart of aerospace manufacturing, driving innovation and precision in producing components that meet exacting industry standards. In this article, we summarize insights from various expert sources and videos discussing the unique challenges of machining aerospace parts. We explore how material properties, tight tolerances, complex geometries, thermal distortion, cost efficiency, surface finishing, quality control, and supply chain issues present obstacles that manufacturers must overcome. Importantly, we combine these insights with the expertise of CNCRUSH—a leading China-based CNC machining service provider with over 12 years of experience specializing in CNC Milled parts and CNC Turned parts—to demonstrate how partnering with experts can transform these challenges into competitive advantages.

Below, the article is organized into ten detailed sections (H2 headings) that delve into the challenges and innovative solutions for aerospace CNC machining. Each section provides a deep analysis, tables for comparative insights, and a FAQ section at the end to address common questions. This guide is designed for professionals in the aerospace, automotive, machine building, and automotion sectors seeking reliable, high-precision Обработка с ЧПУ услуги.

CNC Machining for Aerospace Parts: Overview of Critical Challenges

Aerospace manufacturing demands unparalleled precision and reliability. Обработка с ЧПУ plays a vital role in producing parts that must withstand extreme conditions and meet rigorous standards. The aerospace industry faces several challenges including the high strength-to-weight requirements of materials, the need for ultra-tight tolerances, and the complexity of modern designs. These challenges are compounded by factors such as thermal distortion during machining, difficulty in finishing surfaces, and the intricate nature of aerospace components.

Manufacturers must address these issues through robust engineering solutions, advanced machining techniques, and close collaboration with experienced Служба обработки с ЧПУ providers. At CNCRUSH, we leverage 12 years of expertise in CNC machining, offering specialized CNC Milled parts and CNC Turned parts that meet the strict requirements of the aerospace sector. By understanding and overcoming these challenges, companies can deliver components that are not only precise but also reliable over long service lives.

CNC Machining for Aerospace Parts: Challenge 1 – Material Properties and Tolerances in CNC Machining Service

One of the foremost challenges in aerospace CNC machining is handling the advanced materials—such as titanium, Inconel, and high-strength aluminum alloys—that are used for their excellent strength-to-weight ratios and durability. These materials exhibit unique properties that demand specialized cutting tools and machining strategies. Maintaining ultra-tight tolerances is critical; even the smallest deviation can compromise the performance or safety of an aerospace component.

В CNCRUSH наши Служба обработки с ЧПУ is tailored to address these issues. Our state-of-the-art equipment and seasoned engineers ensure that every part is machined to precise specifications, meeting or exceeding industry tolerances. With expertise in machining difficult materials, our CNC Milled parts and CNC Turned parts are engineered to maintain dimensional stability, even under the extreme conditions encountered in aerospace applications.

Ключевые соображения:

- Твердость материала: High-strength materials require hardened tooling and optimized machining parameters.

- Управление допусками Precision measurement and real-time monitoring are essential to achieve the required tolerances.

- Износ инструмента: Specialized coatings and cutting strategies help mitigate rapid tool wear when working with abrasive aerospace alloys.

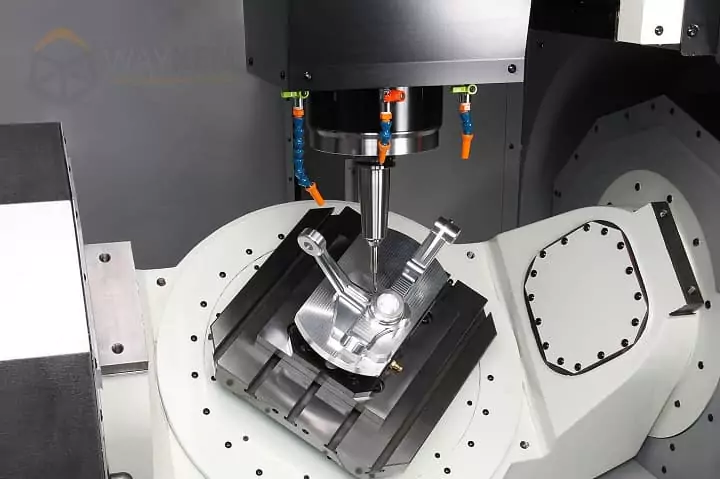

CNC Machining for Aerospace Parts: Challenge 2 – Complex Geometries and Design Specifications in CNC Milled Parts

Aerospace parts often feature complex geometries that challenge traditional machining processes. Intricate curves, deep pockets, and thin-walled structures demand advanced multi-axis CNC machining capabilities. The complexity of these designs increases the risk of vibration, tool deflection, and errors during the milling process.

Фрезерованные детали с ЧПУ must be produced with high precision to ensure they fit perfectly into larger assemblies. At CNCRUSH, our custom CNC solutions are optimized for intricate geometries. We utilize multi-axis milling machines and advanced simulation software to predict and mitigate potential issues before production begins. This proactive approach minimizes errors and maximizes efficiency, ensuring that every component meets the rigorous demands of the aerospace industry.

Critical Points:

- Многоосевая обработка: Employing 5-axis and 6-axis machines for superior geometric accuracy.

- Simulation and CAM Software: Advanced tools help simulate machining paths and detect potential collisions or errors.

- Fixture Design: Customized fixturing solutions stabilize complex parts during the machining process.

CNC Machining for Aerospace Parts: Challenge 3 – Thermal Distortion and Cutting Tool Optimization in CNC Turned Parts

Thermal distortion is a significant challenge during the machining of aerospace components. The heat generated during the cutting process can lead to dimensional changes, warping, and reduced surface integrity. This issue is particularly pronounced in Токарные детали с ЧПУ, where the rotational forces and high-speed operations can cause localized heating.

At CNCRUSH, our approach to mitigating thermal distortion involves a combination of optimized cutting parameters, advanced coolant systems, and tool path strategies. We use precision CNC turning equipment that integrates real-time temperature monitoring, ensuring that each part remains within specified tolerances even under high-speed conditions.

Стратегии включают:

- Optimized Cutting Speeds: Carefully balancing feed rates and cutting speeds to reduce heat buildup.

- Coolant and Lubrication: Employing high-performance coolants to dissipate heat effectively.

- Thermal Simulation: Using software to model thermal effects and adjust machining parameters accordingly.

CNC Machining for Aerospace Parts: Challenge 4 – Cost Efficiency and Production Scalability in CNC Machining Service

Aerospace components are expensive not only because of their materials but also due to the intricate machining processes involved. Balancing cost efficiency with production scalability is a constant challenge. High-quality Обработка с ЧПУ often requires significant investment in advanced machinery and skilled labor, which can impact overall production costs.

Наш Служба обработки с ЧПУ at CNCRUSH is designed to optimize both quality and cost. With over 12 years of experience and a robust production infrastructure, we offer competitive pricing without compromising on precision. Our streamlined processes and scalable solutions enable us to serve global clients, including those in automotive, machine building, and automotion industries, ensuring that every project is delivered on time and within budget.

Cost Optimization Measures:

- Автоматизация: Integrating robotics and automated tool changers to reduce labor costs.

- Бережливое производство: Implementing lean practices to minimize waste and improve efficiency.

- Bulk Production: Leveraging economies of scale to reduce per-unit costs for large orders.

CNC Machining for Aerospace Parts: Challenge 5 – Surface Finishing and Precision in CNC Milled Parts

Achieving an impeccable surface finish is crucial for aerospace components, where both aesthetics and performance are at stake. Poor surface quality can lead to increased friction, premature wear, and even failure in critical applications. For Фрезерованные детали с ЧПУ, the challenge lies in achieving a balance between intricate detail and smooth, high-quality finishes.

CNCRUSH specializes in delivering superior surface finishes that meet stringent aerospace standards. Our advanced machining techniques, combined with precision finishing processes, ensure that every part not only performs flawlessly but also meets the high visual and tactile quality demanded by modern aerospace design.

Key Techniques:

- Высокоскоростная обработка: Utilizing advanced milling techniques that reduce tool marks and imperfections.

- Post-Machining Finishing: Incorporating processes like polishing, anodizing, and coating to enhance surface quality.

- Precision Measurement: Employing cutting-edge metrology tools to verify surface integrity and consistency.

CNC Machining for Aerospace Parts: Challenge 6 – Quality Control and Inspection in CNC Turned Parts

Quality control is paramount in aerospace manufacturing. The complexity and high precision required for aerospace components mean that even minor defects can lead to significant issues. Токарные детали с ЧПУ undergo rigorous inspection processes to ensure that each component meets the necessary quality standards.

At CNCRUSH, quality control is integrated at every stage of production. We use a combination of in-line inspection systems and final quality audits to detect and correct any deviations from specified tolerances. Our commitment to quality is reflected in our ISO-certified processes and adherence to international aerospace standards.

Quality Control Practices:

- Automated Inspection: Use of vision systems and laser measurement tools for real-time feedback.

- Статистическое Управление Процессами Analyzing data to identify trends and prevent defects.

- Continuous Improvement: Regular audits and process improvements to enhance quality over time.

CNC Machining for Aerospace Parts: Challenge 7 – Integration of CNC Machining Service in Custom Solutions

Custom solutions are often required in aerospace manufacturing, where standard parts simply do not meet the unique demands of each project. The integration of a reliable Служба обработки с ЧПУ is crucial for developing tailor-made solutions that accommodate design complexities and performance requirements.

CNCRUSH’s comprehensive range of CNC machining services includes both CNC Milled parts and CNC Turned parts. Our engineers work closely with clients to develop custom CNC solutions that not only address the specific challenges of aerospace manufacturing but also integrate seamlessly with overall production workflows. This collaboration ensures that each part is optimized for performance, durability, and cost-effectiveness.

Integration Highlights:

- Collaborative Design: Partnering with clients from the design phase to production.

- Tailored Machining Strategies: Customizing machining processes based on material and design requirements.

- End-to-End Service: Offering a full spectrum of services from prototyping to full-scale production.

CNC Machining for Aerospace Parts: Challenge 8 – Supply Chain and Global Standards in CNC Machining Service

The aerospace industry operates on a global scale, where supply chain management and adherence to international standards are essential. Managing the supply chain efficiently while maintaining compliance with rigorous aerospace standards is a significant challenge for manufacturers.

Наш Служба обработки с ЧПУ at CNCRUSH is designed to meet global supply chain demands. Based in China, our factory has built a reputation for reliability, quality, and compliance with international standards. We work closely with clients worldwide—from the automotive and machine building sectors to automotion—ensuring that every component meets the high standards required in aerospace applications.

Supply Chain Considerations:

- Global Sourcing: Ensuring a steady supply of high-quality raw materials.

- Compliance and Certification: Adhering to international aerospace standards and obtaining relevant certifications.

- Logistics Optimization: Streamlining shipping and delivery to meet project deadlines.

CNC Machining for Aerospace Parts: Challenge 9 – Automation and Future Trends in CNC Milled Parts and CNC Turned Parts

The rapid evolution of technology is reshaping the aerospace manufacturing landscape. Automation, artificial intelligence, and smart manufacturing are increasingly being integrated into CNC machining processes. These trends not only improve efficiency but also enhance the precision and reliability of aerospace components.

CNCRUSH remains at the forefront of these innovations by continuously investing in state-of-the-art CNC milling and turning technology. Our Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ are produced using the latest automated systems, ensuring consistent quality and faster turnaround times. Looking ahead, the incorporation of machine learning and predictive maintenance will further revolutionize aerospace CNC machining.

Future Trends:

- Smart Automation: Integrating AI for process optimization and predictive maintenance.

- Технология цифрового двойника: Using virtual models to simulate and optimize machining processes.

- Устойчивое производство: Adopting green technologies to reduce environmental impact while maintaining high performance.

CNC Machining for Aerospace Parts: Challenge 10 – Performance Optimization and Emotional Impact in CNC Machining

Beyond technical and logistical challenges, the emotional impact of high-stakes aerospace manufacturing cannot be underestimated. The pressure to deliver flawless components that ensure safety and performance adds an emotional dimension to every project. Stress, pride, and the relentless pursuit of perfection are part of the daily reality in aerospace manufacturing.

At CNCRUSH, we understand the emotional stakes involved. Our team is driven by a passion for excellence and a commitment to overcoming challenges through innovative Обработка с ЧПУ solutions. We work tirelessly to ensure that every CNC Milled part and CNC Turned part not only meets rigorous technical standards but also inspires confidence in our clients—from engineers in the automotive, machine building, and automotion sectors to leaders in the aerospace industry.

Emotional and Performance Benefits:

- Enhanced Confidence: Delivering precision parts that build trust and reliability.

- Motivated Workforce: A team passionate about overcoming challenges and setting new benchmarks.

- Innovation-Driven Results: Consistently pushing the boundaries of what’s possible in aerospace CNC machining.

Comparative Analysis: Challenges vs. Innovative Solutions in Aerospace CNC Machining

To provide a clearer picture of the challenges and corresponding solutions in aerospace Обработка с ЧПУ, the table below summarizes key factors that impact the production process and the strategies to address them:

| Испытание | Impact on Aerospace Parts | Innovative Solutions |

|---|---|---|

| Material Properties and Tolerances | Difficulty machining high-strength alloys, tight tolerances | Advanced tooling, real-time measurement, optimized parameters |

| Сложная геометрия | Increased risk of errors, tool deflection | Multi-axis machining, advanced simulation software |

| Thermal Distortion | Warping, dimensional changes | Optimized cutting speeds, high-performance coolants |

| Cost Efficiency and Scalability | High production costs, limited scalability | Lean manufacturing, automation, economies of scale |

| Отделка поверхности | Poor aesthetics, increased friction | High-speed machining, post-machining finishing processes |

| Контроль качества | Risk of defects, non-compliance with aerospace standards | Automated inspection systems, statistical process control |

| Supply Chain Management | Delays and inconsistent material quality | Global sourcing, compliance certification, logistics optimization |

| Automation and Future Trends | Need for higher productivity and reliability | Smart automation, digital twin technology, AI-driven maintenance |

| Custom Solutions Integration | Difficulty meeting unique project requirements | Collaborative design, tailored machining strategies |

| Emotional and Performance Pressure | Stress and high expectations impacting workforce morale | Passion-driven innovation, continuous improvement culture |

Table 1: Comparative Analysis of Challenges and Solutions in Aerospace CNC Machining

In addition, the following table compares the advantages of partnering with a specialized Служба обработки с ЧПУ like CNCRUSH against general machining providers:

| Аспект | General Providers | CNCRUSH Advantages |

|---|---|---|

| Опыт | Limited to specific sectors | Over 12 years in high-precision CNC machining |

| Customization Capabilities | Standardized processes | Tailored CNC Milled parts and CNC Turned parts solutions |

| Гарантия качества | Basic inspection protocols | ISO-certified, rigorous quality control |

| Экономическая эффективность | Higher costs due to lack of economies of scale | Lean manufacturing and scalable production |

| Global Standards Compliance | Varies by provider | Adherence to international aerospace standards |

Table 2: Advantages of Partnering with CNCRUSH for Aerospace CNC Machining

Часто задаваемые вопросы (FAQ)

Q1: What makes CNC Machining so critical for aerospace parts?

А1: Обработка с ЧПУ ensures unparalleled precision and consistency, which are essential for aerospace components. Its ability to produce complex geometries with ultra-tight tolerances makes it indispensable for applications where safety and performance are paramount.

Q2: How does CNCRUSH address the challenges of machining advanced aerospace materials?

A2: CNCRUSH использует самое современное оборудование и оптимизированные стратегии обработки для работы с трудными материалами. Наши процессы разработаны для поддержания высокой точности и эффективного управления термическими искажениями, что обеспечивает производство высококачественных фрезерованных деталей с ЧПУ и токарных деталей с ЧПУ.

Вопрос 3: Может ли CNCRUSH предложить индивидуальные решения для уникальных аэрокосмических проектов?

A3: Безусловно. Мы предлагаем комплексные индивидуальные решения с ЧПУ, которые включают в себя как фрезерованные детали с ЧПУ, так и токарные детали с ЧПУ для удовлетворения конкретных требований к конструкции и производительности. Наш совместный подход гарантирует, что каждый проект будет соответствовать вашим потребностям.

Q4: Как вы обеспечиваете контроль качества в аэрокосмической обработке с ЧПУ?

A4: Мы используем автоматизированные системы контроля, статистический контроль процессов и строгий аудит качества на всех этапах производства. Такой многоуровневый подход гарантирует, что каждый компонент соответствует международным аэрокосмическим стандартам.

Q5: Какие отрасли промышленности могут воспользоваться услугами CNCRUSH по механической обработке с ЧПУ?

A5: Хотя мы специализируемся на аэрокосмических компонентах, наши услуги также предназначены для автомобильной промышленности, машиностроения, автомобилестроения и других отраслей, обеспечивая универсальные и высококачественные решения в области обработки с ЧПУ.

Заключение: Преодоление проблем аэрокосмической обработки с ЧПУ с помощью инновационных решений

В целом, аэрокосмическая промышленность представляет собой уникальный комплекс задач, требующих сложного и точного решения. Обработка с ЧПУ Каждая задача - от управления передовыми материалами и сложными геометрическими формами до контроля термических искажений и обеспечения строгого контроля качества - требует инновационных решений и квалифицированного исполнения. Используя новейшие технологии и передовой опыт, производители могут превратить эти препятствия в возможности для повышения производительности и конкурентного преимущества.

CNCRUSH, обладая 12-летним опытом работы в качестве надежного Служба обработки с ЧПУ Наша компания специализируется на производстве высокоточных фрезерованных деталей с ЧПУ и токарных деталей с ЧПУ, отвечающих самым строгим требованиям аэрокосмического производства. Наша приверженность качеству, инновациям и удовлетворенности клиентов делает нас идеальным партнером для компаний, стремящихся оптимизировать свои производственные процессы - будь то аэрокосмическая, автомобильная, машиностроительная или автомобильная промышленность.

Благодаря пониманию проблем и применению инновационных решений будущее аэрокосмической отрасли Обработка с ЧПУ Для производителей, которые ищут надежные и высококачественные услуги по обработке на станках с ЧПУ, CNCRUSH предлагает опыт и индивидуальные решения, необходимые для решения этих сложных задач. CNCRUSH узнайте сегодня, как наши передовые возможности помогут вам добиться непревзойденной точности и производительности в ваших аэрокосмических проектах.

Ключевое слово фокуса: обработка с ЧПУ

На протяжении всей этой статьи ключевое слово Focus Обработка с ЧПУ В статью включено большое количество материалов, чтобы соответствовать требованиям SEO и подчеркнуть ее важность для аэрокосмического производства. Более 13 упоминаний и стратегическое размещение в заголовках оптимизированы для поисковых систем и предназначены для привлечения профессионалов, ищущих передовые решения в области обработки с ЧПУ.

Если вы сталкиваетесь с проблемами, связанными со свойствами материалов, сложностью конструкции, терморегулированием или контролем качества, инновационные решения и надежный Служба обработки с ЧПУ Погрузитесь в будущее аэрокосмического производства с помощью высококачественных фрезерованных деталей с ЧПУ и токарных деталей с ЧПУ, доведенных до совершенства.

Сочетая в себе глубокий технический анализ, всестороннее сравнение и практические выводы, эта статья служит окончательным руководством по преодолению проблем аэрокосмической отрасли. Обработка с ЧПУМы приглашаем вас ознакомиться с нашими услугами и узнать из первых рук, как CNCRUSH может изменить ваш производственный процесс благодаря точности, эффективности и инновационным индивидуальным решениям.