Фрезерование с ЧПУ is the cornerstone of modern metalworking, enabling the production of high-precision components critical for industries such as aerospace, automotive, machine building, and automotion. In this comprehensive article, we summarize insights from leading sources on CNC manufacturing, precision CNC milling basics, and the multifaceted applications of CNC machining. By integrating these insights with the expertise of CNCRUSH—a trusted China-based Служба обработки с ЧПУ provider with 12+ years of experience specializing in Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ—we reveal 10 powerful secrets that drive exceptional precision and efficiency in metalworking.

This guide provides a deep dive into the fundamentals, benefits, and challenges of CNC Milling, presenting 10 in-depth discussions. Each section offers detailed analysis, comparative data through tables, and a FAQ section addressing common queries. Whether you are an engineer, production manager, or a decision-maker in high-precision metal fabrication, this article will equip you with the knowledge to optimize your manufacturing processes using advanced CNC Milling techniques.

1. CNC Milling: Understanding the Basics of High-Precision Metalworking

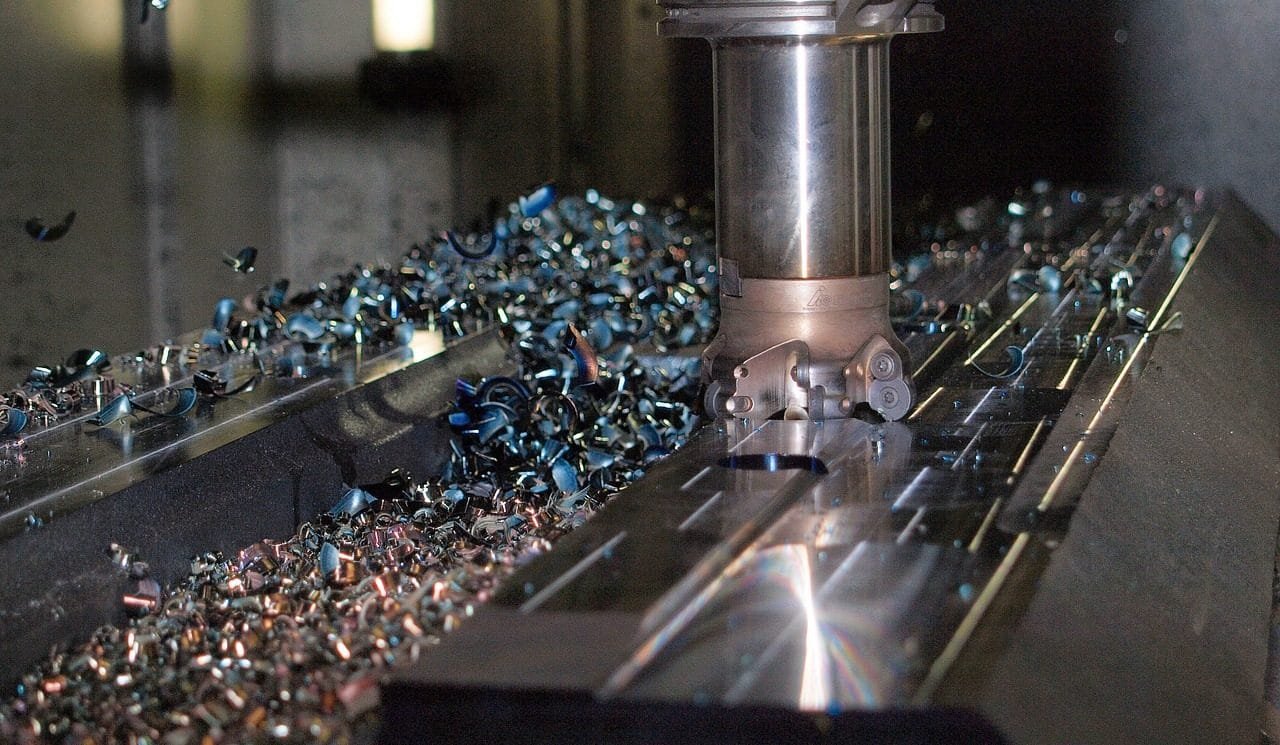

Фрезерование с ЧПУ is a subtractive manufacturing process where material is removed from a workpiece using rotating cutting tools. This process is essential for producing complex, precise components with tight tolerances and excellent surface finishes. Its versatility makes it a preferred method for both prototyping and production across various industries.

Key Concepts:

- Subtractive Process: Material is removed from a solid block, resulting in high-precision parts.

- Automation and Consistency: CNC Milling machines offer repeatability that minimizes human error.

- Универсальные приложения: Capable of machining a range of materials including aluminum, steel, brass, and plastics.

Understanding these basics sets the stage for exploring how CNC Milling transforms metalworking, making it indispensable for high-precision applications.

2. CNC Milling in Advanced Metalworking: The Impact on CNC Machining Service

High-precision metalworking demands robust and reliable processes. Фрезерование с ЧПУ not only meets these demands but also revolutionizes production workflows. For companies looking for a professional Служба обработки с ЧПУ, leveraging CNC Milling means increased accuracy, reduced waste, and superior product consistency.

Benefits for CNC Machining Service Providers:

- Enhanced Precision: Achieve tighter tolerances essential for high-quality components.

- Повышенная эффективность: Reduced need for secondary finishing operations.

- Экономическая эффективность: Optimized processes lead to lower production costs in the long run.

By partnering with experienced providers like CNCRUSH, clients can access custom solutions that incorporate both Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ, ensuring that every component meets the highest standards required in industries such as automotive and machine building.

3. The Role of CNC Milling in Creating Superior CNC Milled Parts

Фрезерование с ЧПУ is the foundation for producing high-quality Фрезерованные детали с ЧПУ. It enables manufacturers to achieve intricate designs and fine details that are crucial for modern applications. This section explores how CNC Milling contributes to the production of durable and precise components.

Critical Advantages:

- Точность размеров: Гарантирует соответствие деталей точным спецификациям.

- Surface Quality: Produces smooth finishes that often require little to no post-processing.

- Сложная геометрия: Enables machining of parts with multiple curves and angles in a single setup.

For businesses requiring exceptional Фрезерованные детали с ЧПУ, utilizing advanced CNC Milling techniques is vital. CNCRUSH’s extensive experience in precision metalworking guarantees that every part is produced with unmatched quality and precision.

4. CNC Milling Techniques in CNC Turned Parts Production for Enhanced Metalworking

Пока Фрезерование с ЧПУ is renowned for its capabilities in subtractive manufacturing, it also plays a significant role in complementing Токарные детали с ЧПУ production. By integrating both milling and turning processes, manufacturers can create hybrid components that benefit from the strengths of each technique.

Key Integration Strategies:

- Hybrid Machining: Combining milling and turning operations to produce components with complex features.

- Оптимизация пути инструмента: Ensuring smooth transitions between milling and turning processes.

- Повышенная гибкость: Meeting diverse production needs by using a multi-process approach.

CNCRUSH’s dual expertise in producing both Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ allows them to offer comprehensive solutions that cover the entire spectrum of high-precision metalworking needs. This integration is particularly valuable for industries that demand intricate designs and robust performance.

5. The Advantages of CNC Milling for Metal Fabrication in Automotive and Machine Building

The automotive and machine building sectors require components that are both durable and precisely engineered. Фрезерование с ЧПУ offers significant benefits in these industries by ensuring high repeatability, minimal deviations, and exceptional material integrity.

Industry Benefits:

- Structural Integrity: Milling produces parts that can withstand high stresses and strains.

- Настройка: Tailored machining solutions meet unique design requirements.

- Эффективность: Fast production cycles enable quick turnaround times for high-volume orders.

For automotive and machine building applications, partnering with a proficient Служба обработки с ЧПУ provider like CNCRUSH ensures that every part—from Фрезерованные детали с ЧПУ к Токарные детали с ЧПУ—is manufactured to the highest quality standards.

6. CNC Milling vs. Traditional Manufacturing Methods: A Comparative Analysis

Comparing Фрезерование с ЧПУ with traditional manufacturing methods highlights its transformative impact on metalworking. The following table summarizes the key differences and advantages:

Table 1: Traditional Manufacturing vs. CNC Milling

| Параметр | Традиционные методы | Фрезерование с ЧПУ |

|---|---|---|

| Точность | Lower; relies on manual adjustments | High; automated with tight tolerances |

| Повторяемость | Inconsistent due to human error | Consistent and repeatable |

| Поверхностная обработка | Often requires additional finishing | Superior finish with minimal post-processing |

| Скорость производства | Slower; multiple setups required | Faster; optimized for high-volume production |

| Гибкость | Limited to simpler geometries | Capable of complex, multi-dimensional designs |

This comparative analysis underscores why Фрезерование с ЧПУ has become the industry standard for high-precision metal fabrication, delivering clear advantages in terms of accuracy, efficiency, and overall quality.

7. Enhancing CNC Machining Service with Advanced CNC Milling Technology

Modern Фрезерование с ЧПУ technology integrates advanced features that significantly enhance the performance of Служба обработки с ЧПУ providers. These advancements drive improvements in efficiency, accuracy, and overall production capabilities.

Key Technological Advancements:

- Высокоскоростная обработка (HSM): Enables rapid cutting speeds without compromising accuracy.

- Multi-Axis Control: Allows for the simultaneous movement of cutting tools along multiple axes, reducing setup times.

- Адаптивные системы управления: Utilize real-time feedback to adjust cutting parameters dynamically.

- Computer-Aided Design/Manufacturing (CAD/CAM): Streamlines the production process by integrating design and manufacturing workflows.

For companies that rely on high-quality Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ, these technological innovations ensure that production processes remain efficient and competitive. CNCRUSH’s investment in state-of-the-art CNC Milling technology reflects its commitment to delivering top-tier Служба обработки с ЧПУ решения.

8. CNC Milling: Key Challenges and How to Overcome Them in High-Precision Metalworking

Despite its many advantages, Фрезерование с ЧПУ comes with its own set of challenges. These can include issues related to tool wear, thermal distortion, and programming complexities. Addressing these challenges is essential for maintaining high precision in metalworking.

Общие проблемы:

- Tool Wear and Tear: Regular maintenance and the use of advanced coatings can mitigate tool degradation.

- Thermal Distortion: Implementing proper coolant systems and optimized cutting speeds helps control heat buildup.

- Programming Complexity: Utilizing advanced CAM software and experienced programmers ensures accurate tool paths.

- Material Variability: Different metals require tailored machining parameters to achieve optimal results.

By proactively addressing these challenges, manufacturers can achieve more consistent results and extend the longevity of their CNC Milling equipment. CNCRUSH’s robust quality control and maintenance practices ensure that potential issues are identified and resolved before they impact production.

9. Future Trends in CNC Milling: Innovation and Sustainability in Metalworking

Будущее Фрезерование с ЧПУ is marked by rapid technological innovation and a growing focus on sustainable practices. Emerging trends are set to transform the way high-precision metalworking is performed, making production even more efficient and environmentally friendly.

Новые тенденции:

- Искусственный интеллект и машинное обучение: Predictive analytics to optimize tool paths and maintenance schedules.

- Технология цифрового двойника: Virtual simulations of machining processes to preemptively identify and resolve issues.

- Eco-Friendly Machining: Techniques designed to reduce energy consumption and material waste.

- Гибридное производство: Combining CNC Milling with additive manufacturing (3D printing) for enhanced design flexibility.

CNCRUSH is committed to staying ahead of these trends by continuously updating its processes and equipment. As a leading Служба обработки с ЧПУ provider, CNCRUSH leverages the latest advancements to deliver innovative solutions for Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ, ensuring sustainable and cutting-edge production practices.

10. How to Choose the Right CNC Milling Partner: Insights from a Leading CNC Machining Service Provider

Selecting the right partner for high-precision CNC precision Milling is critical for achieving manufacturing excellence. Companies must evaluate potential partners based on several factors including experience, technological capabilities, and customer support.

Key Selection Criteria:

- Experience and Expertise: Look for providers with a proven track record in high-precision metalworking.

- Передовые технологии: Ensure the provider uses state-of-the-art CNC precision Milling machines and integrated CAM systems.

- Гарантия качества: Certifications such as ISO and stringent quality control measures are essential.

- Возможности настройки: The ability to produce tailored Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ for specific industry needs.

- Отзывы клиентов: Positive testimonials and case studies from industries like automotive, machine building, and automotion.

CNCRUSH meets all these criteria with over 12 years of experience and a commitment to continuous improvement. Their comprehensive Служба обработки с ЧПУ covers everything from prototype development to full-scale production, ensuring that every component is manufactured to the highest standards.

Comparative Analysis: CNC Milling vs. Other CNC Machining Techniques

To illustrate the unique benefits of Фрезерование с ЧПУ, the following tables offer a side-by-side comparison of CNC Milling with other common machining techniques.

Table 2: CNC Milling Compared to Other Techniques

| Параметр | Фрезерование с ЧПУ | Other CNC Machining (e.g., Turning, 3-Axis) |

|---|---|---|

| Точность | High; capable of complex geometries | Moderate; limited by fewer axes |

| Поверхностная обработка | Excellent; minimal post-processing needed | Often requires additional finishing |

| Гибкость | Versatile; suitable for intricate designs | Less versatile; simpler geometries |

| Время цикла | Optimized for high efficiency | Длительно из-за нескольких настроек |

| Tool Utilization | Advanced tool paths reduce wear | Higher wear and tear with repetitive cuts |

Table 3: Benefits of Partnering with CNCRUSH for CNC Milling

| Аспект | General Providers | CNCRUSH Advantages |

|---|---|---|

| Опыт | Переменная | 12+ years of high-precision expertise |

| Кастомизация | Standardized solutions | Tailored CNC Milled parts and CNC Turned parts |

| Technological Integration | Basic CNC setups | State-of-the-art CNC Milling & Turning equipment |

| Контроль качества | Inconsistent quality | Rigorous, ISO-certified quality protocols |

| Industry Compliance | Often limited | Comprehensive solutions for automotive, machine building, and automotion |

FAQ: CNC Milling in High-Precision Metalworking

Q1: What is CNC Milling and why is it important for metalworking?

А1: Фрезерование с ЧПУ is a subtractive manufacturing process that uses rotating cutting tools to remove material from a workpiece. It is crucial for producing high-precision components with complex geometries and excellent surface finishes, making it essential in industries like aerospace, automotive, and machine building.

Вопрос 2: Как фрезерная обработка с ЧПУ улучшает производство фрезерованных и токарных деталей с ЧПУ?

A2: Фрезерная обработка с ЧПУ позволяет создавать сложные конструкции с жесткими допусками, уменьшая необходимость в многократной настройке и вторичной обработке. Это приводит к превосходному Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ которые отвечают высоким стандартам качества и точности.

Q3: Может ли фрезерная обработка с ЧПУ снизить общие производственные затраты?

A3: Да, хотя прецизионная фрезерная обработка с ЧПУ может потребовать больших первоначальных инвестиций, ее способность сокращать время наладки, минимизировать отходы материалов и повышать эффективность производства в конечном итоге снижает общие затраты при крупносерийном производстве.

Q4: Какие отрасли промышленности больше всего выигрывают от фрезерной обработки с ЧПУ?

A4: Такие отрасли, как аэрокосмическая, автомобильная, машиностроительная и автомобильная, получают значительную выгоду от прецизионной фрезерной обработки с ЧПУ благодаря ее способности производить сложные высокоточные компоненты, необходимые для обеспечения безопасности и производительности.

Q5: Как я могу начать пользоваться услугами CNCRUSH по фрезерованию с ЧПУ?

A5: Visit CNCRUSH чтобы узнать больше о нашей комплексной программе Служба обработки с ЧПУ Предложения, включая индивидуальные решения для Фрезерованные детали с ЧПУ и Токарные детали с ЧПУНаша опытная команда проведет вас через все этапы процесса.

Заключение: Преобразование металлообработки с помощью фрезерной обработки с ЧПУ

В заключение, Фрезерование с ЧПУ Эта технология позволяет изготавливать сложные детали, отвечающие самым строгим требованиям современных отраслей промышленности, от аэрокосмической и автомобильной до машиностроения и автомобилестроения. В этом руководстве раскрываются 10 секретов освоения прецизионной фрезерной обработки с ЧПУ, от понимания ее фундаментальных процессов до использования передовых технологий и преодоления типичных проблем.

Сотрудничая с таким надежным поставщиком, как CNCRUSH, производители получают доступ к услугам экспертов. Служба обработки с ЧПУ который обеспечивает превосходное Фрезерованные детали с ЧПУ и Токарные детали с ЧПУ CNCRUSH, обладая более чем 12-летним опытом и приверженностью к качеству, стремится к инновациям и совершенству в области производства металлоконструкций.

Откройте для себя будущее высокоточной металлообработки с помощью передовой технологии прецизионного фрезерования с ЧПУ. Оцените преимущества, преодолейте трудности и измените свой производственный процесс с помощью передовых решений, которые всегда обеспечивают превосходные результаты. Для получения дополнительной информации о том, как CNCRUSH может расширить ваши производственные возможности, посетите сайт CNCRUSH сегодня и узнайте, что такое настоящая точность.