CNC Machining is the backbone of modern aerospace manufacturing, providing critical capabilities to produce high-performance components with micron-level accuracy, shortened lead times, and optimized costs. Below is an in-depth analysis of 10 powerful ways CNC Machining supports the aerospace industry, complete with rich technical insights, process discussions, and cross-sector perspectives. CNCRUSH-tovarna s sedežem na Kitajskem z 12-letnim strokovnim znanjem na področju CNC storitev obdelave, specializirano za CNC rezkani deli in CNC struženi deli—stands ready to meet your most demanding aerospace, automotive, machine building and automotion needs.

1. Storitev CNC strojne obdelave: CNC obdelovalna storitev: Natančna odličnost za CNC rezkane dele

Modern aerospace brackets, ribs, and housings demand surface finishes finer than Ra 0.8 µm and dimensional tolerances down to ±0.005 mm. Our CNC machining service leverages simultaneous multi-axis control to mill free-form contours in one setup, eliminating cumulative errors from multiple fixtures. By optimizing tool paths for constant cutter engagement, we reduce deflection and thermal growth, ensuring consistent part quality across high-volume runs. This level of precision is critical za nosilne komponente letalskega ogrodja, ki so izpostavljene vibracijam, toplotnim ciklom in utrujenosti. Pri obdelavi aluminijastih zlitin za zmanjšanje teže ali trših nikljevih zlitin za visokotemperaturna območja naš pristop k frezanju delov CNC združuje napredne strategije CAM, orodja z visoko trdnostjo in kompenzacijo vretena v realnem času - zagotavlja ponovljivost in celovitost površine, ki ju zahtevajo inženirji letalske industrije.

2. CNC Machining Service: Quality Enhancement for CNC Turned Parts

Landing gear cylinders, actuator rods, and spline shafts require concentricity within ±0.002 mm and surface roughness below Ra 0.4 µm. Integrating live-tool turning with multi-axis machining allows us to produce complex CNC turned parts—including cross-drilling, polygon milling, and undercuts—in a single fixture. Synchronized spindle and rotary table movements optimize chip evacuation and coolant flow, preserving metallurgical integrity when processing titanium and stainless steel alloys. This unified workflow cuts scrap rates by up to 60% and slashes secondary operations, delivering positive cost impacts. With automated tool-life monitoring and adaptive feed adjustments, our CNC machining service ensures each turned component meets the tightest aerospace standards without compromise.

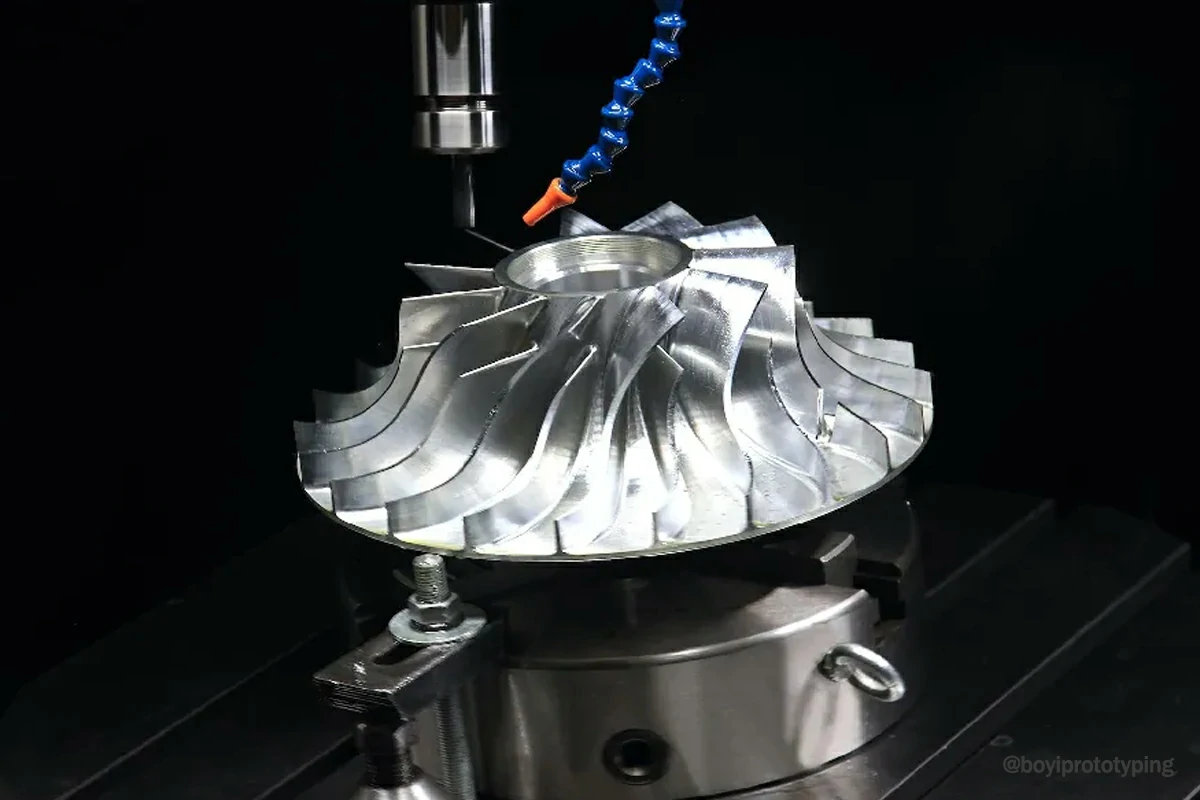

3. CNC obdelava za izdelavo kompleksnih turbinskih lopatic

Turbine blades blend aerodynamic finesse with internal cooling channels, featuring compound curves and deep pockets. Conventional 3-axis mills struggle to access these features without extensive manual setups. Our 5-axis CNC machining centers approach every blade surface in one clamp, enabling precision pocketing of cooling passages and final polishing of aerofoil profiles. Advanced tool-path algorithms adjust tilt angles to maintain optimal cutter contact, reducing wear on expensive carbide and CBN inserts. The result is an extended tool life, smoother blade finishes, and consistent aerodynamic performance. This capability transforms turbine production from a multi-operation chore into a streamlined, high-precision process—boosting engine efficiency and reliability.

4. Storitev CNC strojne obdelave: CNC obdelovalni stroji: hitra izdelava prototipov in CNC rezkani deli Čas izvedbe

Pri raziskavah in razvoju v letalstvu in vesolju je čas bistvenega pomena. CNCRUSH-ova storitev strojne obdelave CNC uporablja breztočkovno vpenjanje in sisteme za hitro menjavo palet, s čimer skrajša čas neobdelovanja za več kot 50%. Inženirji dobijo izrezane dele CNC, kot so nosilci za avioniko in ohišja senzorjev, v dnevih in ne tednih. Naš potek dela združuje digitalne delovne liste, avtomatizirano gnezdenje in spremljanje proizvodnje v realnem času, zato lahko hitro spreminjate modele, ne da bi pri tem žrtvovali natančnost. Ta agilnost je vital za preverjanje skladnosti oblike in delovanja na kritičnih letalskih sistemih ter pospešuje prehod od izdelave prototipa do kvalifikacijskega testiranja, s čimer ohranja časovni razpored razvoja na pravi poti.

5. Storitev CNC strojne obdelave: Napredni materiali za CNC rezkane dele

Aerospace applications increasingly rely on difficult-to-machine alloys like Ti6Al4V, Inconel 718, and carbon-fiber composites for their strength-to-weight benefits. These challenging materials work-harden rapidly and demand precise thermal control. Our CNC machining service employs high-pressure through-spindle coolant, ceramic-coated carbide inserts, and rest-machining strategies to maintain cutting temperatures below critical thresholds. Combined with dynamic tool-path smoothing, we prevent chatter and delamination while achieving fine surface finishes. The result is CNC milled parts that meet or exceed mechanical and fatigue life requirements, enabling designers to push performance envelopes confidently.

6. CNC Machining Service: Automation in CNC Turned Parts Production

To support high-mix, low-volume aerospace and automotive runs, CNCRUSH integrates robotic loading/unloading, in-process laser measurement, and automatic tool changers into our CNC machining service. Real-time telemetry on spindle load, vibration, and tool wear feeds adaptive control systems that optimize feed rates and spindle speeds on the fly. This level of automation ensures consistent quality for both CNC milled parts and CNC turned parts around the clock, drastically improving throughput and reducing human error. Operators shift from manual intervention to overseeing workflows, adding engineering value rather than monitoring machines.

7. CNC Machining Service: Cost Optimization for CNC Milled Parts and CNC Turned Parts

Z združevanjem rezkanja in struženja v enotne celične konfiguracije in zmanjšanjem korakov pritrditve do 80% naša storitev obdelave CNC znatno zmanjša stroške dela in splošne stroške. Algoritmi za gnezdenje materiala povečajo izkoriščenost zalog, medtem ko napovedno načrtovanje vzdrževanja zmanjšuje nenačrtovane zastoje. Ta celostni pristop zagotavlja positive return on investment—even for small-batch aerospace contracts—while ensuring AS9100-level process control. Clients benefit from transparent cost breakdowns, competitive unit pricing, and the ability to scale without capital-intensive infrastructure expansions.

8. Storitev CNC strojne obdelave: V okviru avtomobilske industrije, strojegradnje in avtomobilizma

Although aerospace demands the highest precision, the same CNC machining service workflows apply seamlessly to automotive engine components, transmission housings, and industrial automation tooling. CNCRUSH leverages cross-sector expertise to amortize fixturing and programming investments, passing savings to customers in both high-volume and niche markets. Our facility handles batches from a single prototype to 10,000 pieces, maintaining consistent lead times and quality metrics. This scalability in CNC milled parts and CNC turned parts ensures that whether you’re building a next-gen aircraft or a robotic end-effector, you experience the same reliability and cost efficiency.

9. CNC Machining Service: Metrology and Quality Assurance

Every part we machine undergoes in-process inspection via integrated CMM probes and laser scanners. Dimensional data is captured in real time, feeding back to the CNC controller for adaptive corrections. This closed-loop metrology ensures that each feature—hole position, surface contour, thread form—stays within specified tolerances without manual post-inspection. Digital inspection reports are delivered with each batch, supporting traceability and regulatory compliance. The result is an unwavering commitment to quality across CNC Milled parts and CNC Turned parts, backed by data-driven assurance.

10. CNC Machining Service: Sustainable Practices in Aerospace Manufacturing

Odgovornost do okolja je bistvo naših storitev strojne obdelave CNC. Optimizirane poti orodij zmanjšajo gibe zračnega rezanja do 30% in tako zmanjšajo porabo energije na del. Recikliramo orodja iz karbida in uporabljamo biološko razgradljiva hladilna sredstva na vodni osnovi, da bi zmanjšali ekološki vpliv. Poleg tega spremljanje v realnem času odkriva priložnosti za združevanje nastavitev ali združevanje podobnih opravil, kar še dodatno zmanjša porabo energije. Te trajnostne prakse so v skladu s pobudami za zeleno proizvodnjo v letalski in vesoljski industriji in drugod ter dokazujejo, da lahko natančen inženiring in skrb za okolje napredujeta z roko v roki.

Table 1: CNC Machining Process Comparison

| Vidik | Konvencionalni CNC | Advanced Multi-Axis CNC |

|---|---|---|

| Število nastavitev | 3–5 separate ops | 1 single setup |

| Typical Tolerance | ±0,01 mm | ±0,001 mm |

| Čas izdelave prototipa | Weeks | Dnevi |

| Material Capability | Aluminij, jeklo | Titanium, Inconel, Composites |

| Integracija avtomatizacije | Omejeno | Celoten internet stvari in robotika |

Table 2: Material-Process Recommendations

| Material | Recommended Process | Ključna korist |

|---|---|---|

| Aluminijeve zlitine | 3-osno in 5-osno rezkanje | Fast removal, excellent surface finish |

| Titanove zlitine | 5-osno visokohitrostno rezkanje | Controlled heat, extended tool life |

| Nickel-Based Superalloys | 5-osna površinska obdelava | Reduced work-hardening, high integrity |

| Carbon-Fiber Composites | 5-osno specializirano rezkanje | Minimal delamination, precise contours |

| Hardened Steels | Struženje in rezkanje z živim orodjem | Tesna koncentričnost, natančna površinska obdelava |

pogosta vprašanja

V1: Zakaj je obdelava CNC bistvenega pomena za letalsko in vesoljsko proizvodnjo?

CNC Machining delivers micron-level precision, single-setup complex geometry capability, and material versatility—requirements that are critical za turbinske lopatice, podvozje in hidravlične komponente.

Q2: What services does CNCRUSH provide?

CNCRUSH ponuja storitve na ključ CNC storitev obdelave, specializing in high-precision CNC rezkani deli in CNC struženi deli, backed by AS9100 compliance and 12 years of industry experience.

Q3: Can CNCRUSH handle both prototypes and production batches?

Da - naši avtomatizirani delovni postopki in orodja za hitro menjavo zagotavljajo končne dele CNC rezkane v nekaj dneh za prototipe in obsegajo do 10.000 kosov za proizvodne količine z enako natančnostjo.

Q4: Which industries benefit from CNCRUSH’s CNC Machining Service?

Poleg letalske in vesoljske industrije naše zmogljivosti za kompleksne in zelo natančne dele uporabljajo tudi sektorji, kot so avtomobilska industrija, strojegradnja in avtomobilizem, medicinske naprave in elektronika.

Q5: How do I start a project with CNCRUSH?

Request a quote via our inquiry form; our engineering team will optimize your design for manufacturability and recommend the ideal CNC Machining workflow.