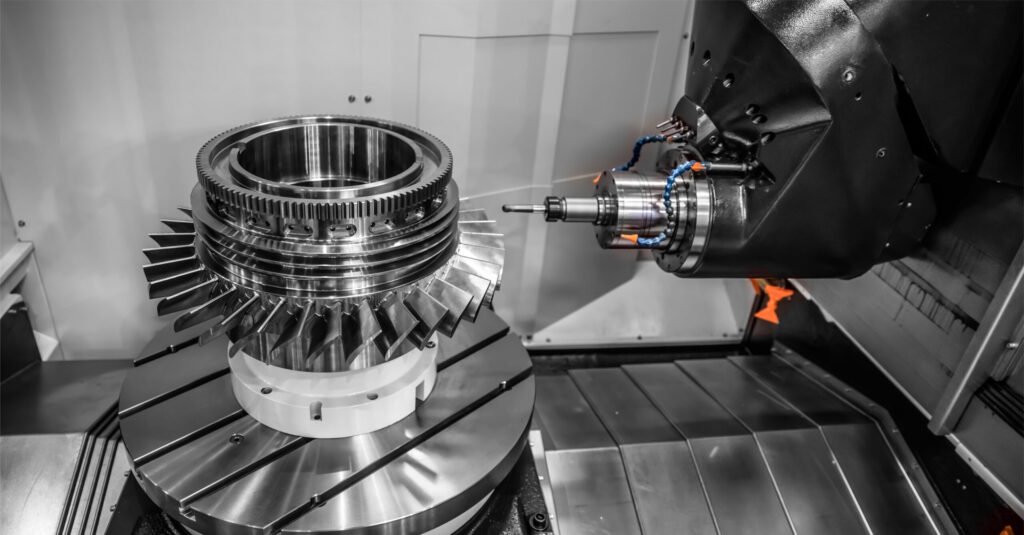

CNCミリングは、自動車、機械製造、オートメーションなどの業界にわたって、複雑な部品の一貫した正確で効率的な生産を可能にすることで、高精度製造の世界に革命をもたらしています。企業がより厳しい公差、より滑らかな仕上げ、より迅速な納品を実現しようと努力する中、CNCミリングは現代の製造業の基礎として際立っています。 1. 高精度製造におけるCNCミリング - 精度のバックボーン CNCミリングは、コンピュータ命令によって制御される切削工具を自動化することで、超精密な操作を可能にします。これらのシステムは、CAD設計を繰り返し可能なコマンドに変換し、最も複雑な形状でもサブミリメートル精度で機械加工できるようにします。オートメーションや自動車などの分野では、特に精度が重要です。ここでは、公差スタックや熱膨張が問題となるためです。

カテゴリーアーカイブ: CNCRUSHニュース

CNC加工部品は、アノダイジング処理により、優れた耐久性、耐腐食性、美観を実現します。CNCRUSHの専門家によるCNC加工サービスとアルミニウムアノダイジングの相乗効果をご紹介します。CNC加工部品は、アルミニウムのアノダイジング処理によって劇的に変貌します。本記事では、業界の主要ガイドラインを調査し、アノダイジングのプロセス、種類、ベストプラクティス、メリットについて詳細な分析を行います。これらは、CNCRUSH(中国拠点のCNC加工サービスプロバイダー)による、12年以上のCNCフライス加工部品およびCNC旋削加工部品の経験によって裏付けられています。自動車、機械製造、オートメーションに焦点を当てている場合であっても、精密加工とアノダイジングの強力な相乗効果は、印象的な結果をもたらします。1. CNC加工部品:アノダイジングの理解とその重要性 アノダイジングは、自然に耐久性のある […]

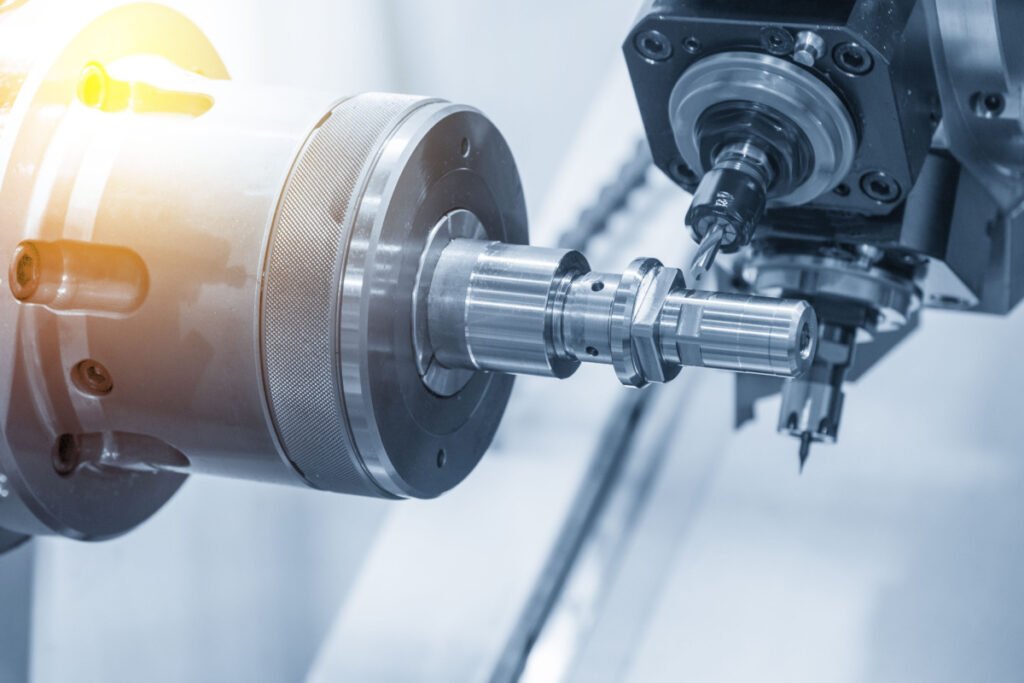

CNC加工は、高い精度、スケーラビリティ、スピードで自動車製造を変革します。CNCRUSHのCNCミルド部品およびCNC旋削部品の12年間の専門知識が、世界中のクライアントをどのようにサポートしているかをご覧ください。 はじめに:CNC加工が自動車部品製造に革命をもたらす CNC加工は、現代の自動車製造の基準を再定義しています。超精密なエンジン部品から軽量のアルミニウムサスペンション部品まで、このデジタルファブリケーション技術は、自動車業界に比類のない精度、再現性、効率をもたらします。広範な産業調査と、CNCRUSHのCNCミルド部品およびCNC旋削部品の12年以上のグローバル自動車および機械製造企業への納入実績から、CNC加工サービスが、OEMおよびアフターマーケットメーカーのイノベーションとコスト効率をどのように推進しているかを探ります。

CNC Machining breakthroughs hinge on precisely optimized feed rates to ensure efficiency and accuracy—CNCRUSH excels in CNC machining service with CNC Milled parts and CNC Turned parts. CNCRUSH offers high-precision CNC machining services, processing aluminum, steel, and plastics. Trusted by global clients for over 12 years. 🔥 CNC Machining Breakthrough: 12 Impactful Insights on Feed Rates in CNC Machining 🔍 Summary of Key Insights The concept of feed rates in CNC Machining is fundamental: controlling how fast the tool advances through material greatly impacts chip load, tool life, surface finish, and part quality. Optimal feed depends on spindle speed (RPM), material type, tool geometry, machine rigidity, and depth of cut. […]

CNC Machining empowers aerospace parts with unmatched precision and reliability—CNCRUSH delivers unparalleled CNC machining service with expert CNC Milled parts and CNC Turned parts. CNCRUSH offers high-precision CNC machining services, processing aluminum, steel, and plastics. Trusted by global clients for over 12 years. 🚀 CNC Machining Power Boost: 9 Game-Changing Strategies for High-Precision Aerospace Parts 🔍 Summary of Key Industry Insights CNC Machining in aerospace demands exceptional accuracy, consistently achieving tolerances within ±0.0001–±0.005inches (≈±0.002–0.127mm). It handles exotic materials—titanium, Inconel, aluminum alloys, composites—and intricate geometries via multi-axis systems. Regulatory demands like AS9100 and NADCAP require traceability, documentation, and quality excellence. Leading shops integrate automation, AI, robotics, and in-process monitoring to ensure […]

CNC Machining for high-precision medical device parts requires meticulous engineering, stringent standards, and deep expertise—CNCRUSH has delivered top-tier results for over 12 years. CNCRUSH offers high-precision CNC machining services, processing aluminum, steel, and plastics. Trusted by global clients for over 12 years. 1. CNC Machining service Excellence in Medical‑Grade Tolerance High‑precision medical parts demand CNC Machining service that consistently achieves tolerances within ±0.005 mm (±0.0002″) or better. This is essential for implant threads, catheter guide holes, and surgical tool fit. Sources note that maintaining such tolerances requires stable machines, specialized tooling, and continuous process verification and calibration . CNCRUSH’s 12 years of experience with CNC Milled parts and CNC Turned parts […]

CNC Machining improves aerospace precision, material handling, and cost-efficiency—discover 10 powerful ways, amps up your manufacturing with CNCRUSH’s expert CNC Machining service. CNC Machining has revolutionized aerospace manufacturing by enabling ultra-precise components production, from turbine blades to structural fasteners. The article consistently highlight: Tight tolerance & complex geometry – CNC’s reliability in achieving ±0.005 mm. High-performance materials – machining titanium, Inconel, and advanced alloys. Quality & certification – aerospace-grade standards (AS9100, NADCAP). Cost/time reduction – via CAM, simulation, and automation. Surface finish & structural integrity – essential for fatigue resistance. 1. CNC Machining Service Enables Aerospace-Grade Precision and Accuracy One of the most critical aspects of aerospace manufacturing is the requirement […]

CNC Machining is the key to precision manufacturing. Discover 14 expert tips to optimize your CNC machining projects, reduce costs, and enhance efficiency. Trust CNCRUSH, your reliable CNC machining service provider with 12 years of experience. CNC Machining stands at the forefront of manufacturing innovation, enabling the production of complex parts with high precision. By automating the control of machining tools through computer programming, CNC machining ensures consistency, reduces human error, and accelerates production timelines. CNC Machining is revolutionizing the manufacturing industry by offering unparalleled precision and efficiency. As we delve into 2025, optimizing CNC machining projects has become more critical than ever. Drawing insights from industry leaders and incorporating […]

CNC Machining is transforming the automotive industry with greater precision, adaptability, and sustainability. Discover 10 powerful trends reshaping CNC machining for automotive manufacturing in 2025 and beyond. CNC Machining is at the forefront of innovation in the automotive industry. As vehicles become smarter, more complex, and environmentally conscious, the demand for precise, scalable, and efficient manufacturing methods is increasing. Based on insights from leading industry reports and expert analyses, this in-depth guide explores the ten key trends shaping the future of CNC machining in the automotive sector, with a strong emphasis on how companies like CNCRUSH, a leading CNC machining service provider in China with over 12 years of experience, […]

CNC Machining plays a pivotal role in the medical device manufacturing industry, ensuring unparalleled precision, customization, and efficiency. Drawing insights from industry-leading resources, this article delves into the top 10 ways CNC precision machining enhances medical device production. For over 12 years, CNCRUSH, a China-based factory, has specialized in providing high-quality CNC machining services, including CNC Milled parts and CNC Turned parts, catering to industries such as automotive, machine building, and automation. 1. CNC Machining: Achieving Unmatched Precision in Medical Devices In the medical field, precision is paramount. CNC precision machining offers exceptional accuracy, producing components with tight tolerances essential for medical devices. This precision ensures the reliability and safety […]