CNC Machining for high-precision medical device parts requires meticulous engineering, stringent standards, and deep expertise—CNCRUSH has delivered top-tier results for over 12 years. CNCRUSH offers high-precision CNC machining services, processing aluminum, steel, and plastics. Trusted by global clients for over 12 years.

1. CNC Machining service Excellence in Medical‑Grade Tolerance

High‑precision medical parts demand CNC Machining service that consistently achieves tolerances within ±0.005 mm (±0.0002″) or better. This is essential for implant threads, catheter guide holes, and surgical tool fit. Sources note that maintaining such tolerances requires stable machines, specialized tooling, and continuous process verification and calibration . CNCRUSH’s 12 years of experience with CNC Milled parts and CNC Turned parts means we have mastered machine calibration and temperature‑controlled environments to guarantee reliable medical tolerance.

2. CNC Machining service with Biocompatible Materials and Surface Integrity

Medical components often use materials like 316L stainless steel, titanium alloys (Ti‑6Al‑4V), PEEK, and UHMWPE. Surface finish is critical to prevent bacterial adhesion and ensure smooth tissue interaction. Post‑processes like electropolishing, passivation, or micro‑blasting are essential . CNCRUSH offers CNC Milled parts and CNC Turned parts finished to Ra ≤ 0.4 µm, with full passivation and traceable documentation—elevating product quality and patient safety.

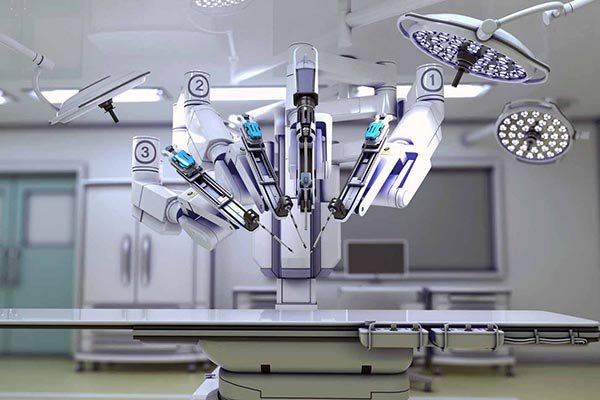

3. CNC Machining service – CNC Milled parts vs CNC Turned parts for Medical Applications

Deciding between CNC milled parts and CNC turned parts depends on geometry. CNC Milled parts excel for complex, multi‑axis shapes like implant housings or fluidic channels. CNC Turned parts work best for cylindrical components like hubs or needle shafts. Efficiency, cycle time, and cost may favor one process. CNCRUSH evaluates design intent and volume to propose the most cost-effective approach—whether that’s CNC Milled parts or CNC Turned parts—while maintaining surgical precision.

4. Regulatory Compliance & Traceability in CNC Machining service

Medical machining must comply with FDA Quality System Regulations (QSR), ISO 13485, and possibly MDR or MDSAP standards . Documented material traceability, machine calibration logs, and process validation are non-negotiable. CNCRUSH maintains ISO 13485 certification and provides full lot traceability on both CNC Milled parts and CNC Turned parts, including certificates of compliance and raw material certificates, supporting seamless audit readiness.

5. CNC Machining service for Small Batch vs. Mass Production

Medical devices span prototypes to large-volume production. Protolabs emphasizes rapid prototyping, while Cox Manufacturing addresses production scalability . CNCRUSH supports prototype batches (10–100pcs) and high-volume orders (thousands), keeping pricing transparent and competitive. Whether CNC Milled parts or CNC Turned parts, our streamlined setup ensures cost efficiency at each scale.

6. CNC Machining service – Tooling, Fixturing & Cleanroom Protocols

Consistency in medical machining mandates robust fixturing, tool control, and contamination control. Many shops are upgrading standard setups to ISO 7/8 cleanrooms post‑machining . CNCRUSH uses dedicated medical machining cells with HEPA‑filtered environments, ultra‑clean tooling, and protocols to avoid cross‑contamination. Each CNC Milled parts or CNC Turned parts batch is cleaned, dried, and packaged per cleanroom standards—ideal for aseptic integration.

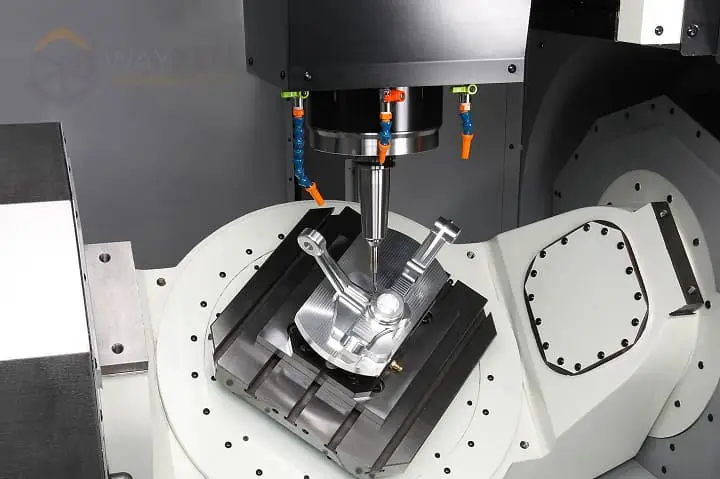

7. CNC Machining service Cost‑Benefit: Material Waste & Cycle Time

Efficient chip-to-part path planning can reduce material waste by 20–40%, as noted in industry blogs . Turned parts often yield less waste for cylindrical shapes. At CNCRUSH, CAM engineers optimize CNC Milled parts and CNC Turned parts for scrap reduction and time minimization. We use powder‑coated fixtures to speed changeovers, achieving lead‑times as short as 5 days for small batches and 15 days for larger runs.

8. CNC Machining service in Automotive, Machine Building and Automotion – Lessons for Medical

Though distinct, the automotive and automation sectors share process rigor with medical machining. High-volume CNC Turned parts in automotion demand consistency and predictive maintenance—which can transfer effectively to medical . CNCRUSH’s involvement in machine building and automation helps fuel best practice convergence: automated tool‑offset compensation, SPC controls, and in‑process gauging benefit both sectors, enhancing quality and efficiency across CNC Milled parts and CNC Turned parts.

9. CNC Machining service – Surface Treatments and Post‑Processing

Here are typical finishing workflows CNCRUSH provides:

| プロセス | 目的 | Surface Finish Achieved |

|---|---|---|

| 電解研磨 | Smoothens micro-burrs/peaks | Ra ≤ 0.2 µm |

| 不動態化 | Removes free iron; improves corrosion resistance | – |

| Sandblasting/Blasting | Enhances aesthetics; rids micro-contamination | Ra 0.4–0.8 µm |

| Anodizing (Aluminum) | Increases wear & biocompatibility | Type II/III possible |

This positive and advanced suite shows how CNC Machining is not just cutting metal—but refining it for life-critical applications.

10. CNC Machining service – Quality Control & Inspection Protocol

Medical parts require 100% inspection via CMM, vision systems, and functional tests . CNCRUSH uses on-machine probing, offline CMM, and full dimensional reports, alongside documentation of lot-by-lot inspection to support compliance, traceability, and zero-defect deliverables for CNC Milled parts and CNC Turned parts.

11. CNC Machining service – Global Sourcing & Turnkey Advantage

Global clients choose CNCRUSH for our 12-year credibility, manufacturing cost benefits, and turnkey service. We source raw materials in line with US/EU standards and offer packaging, kitting, and drop-shipping. For OEMs in North America and Europe, CNCRUSH provides everything from CAD-assisted Design for Manufacturing (DFM) to production-scale CNC Machining—reducing time to market and logistic complexity.

🛠️ Table 2: CNC Machining service – Milled vs Turned Comparison

| 特徴 | CNC フライス加工部品 | CNC旋削部品 |

|---|---|---|

| Part Geometry | Complex 3D shapes, slots, pockets | Cylindrical, shafts, housings |

| 素材の活用 | ~60–70% | ~80–90% (less waste) |

| Tolerance Capability | ±0.005 mm | ±0.003 mm |

| Cycle Time (prototype) | Moderate to long | 速い |

| Batch Size Efficiency | Effective for small to medium | Ideal for medium to large |

| Best Use Case | Custom implants, housings, tooling | Needle hubs, screws, connectors |

FAQ – CNC Machining for Medical Devices

Q1: What certifications does CNCRUSH hold for medical CNC Machining service?

A: CNCRUSH is ISO 13485 certified and implements FDA QSR–aligned quality systems, supports traceability, batch control, and audit‑ready documentation.

Q2: Can CNC Milled parts or CNC Turned parts be supplied with sterile packaging?

A: Yes. We offer cleanroom packaging, gamma-sterilization-ready kits, or sterile barrier bags per client requirements.

Q3: What inspection reports are provided?

A: Every batch includes full CMM data, material certificates, process logs, and first-article inspections. SPC charts available for volume runs.

Q4: Does CNCRUSH support rapid prototyping?

A: Absolutely—our fast-track cell can deliver CNC Milled parts or CNC Turned parts for design verification in as little as 5 days.

Why Choose CNCRUSH for CNC Machining service?

With 12 years of unwavering expertise CNC Machining, we stand out through:

-

Deep technical experience in CNC Milled parts and CNC Turned parts for life-critical applications.

-

Stringent quality systems (ISO 13485, FDA-ready, SPC).

-

Material‑agnostic capabilities—aluminum, stainless, titanium, PEEK.

-

Strong emotional commitment to patient safety and superior performance—every part matters.

-

Cost‑effective, scalable solutions for prototypes to production volumes.

Visiting CNCRUSH lets visitors find not just a service provider—but a trusted partner in CNC Machining for medical device innovation. Our engineered precision can be the difference between great and extraordinary medical outcomes.