CNC Machining is a cornerstone of modern manufacturing that enables the precise production of complex parts across industries. In particular, 5-axis CNC machining has emerged as a game-changing advancement: by adding two rotational axes to a traditional mill, it allows tools to approach the workpiece from virtually any direction. This capability means manufacturers can achieve unparalleled accuracy and tight tolerances – often within microns – on intricate components like medical implants or aerospace parts. Industry experts note that 5-axis machines deliver faster, more accurate, and more complex machining than ever before, revolutionizing precision production.

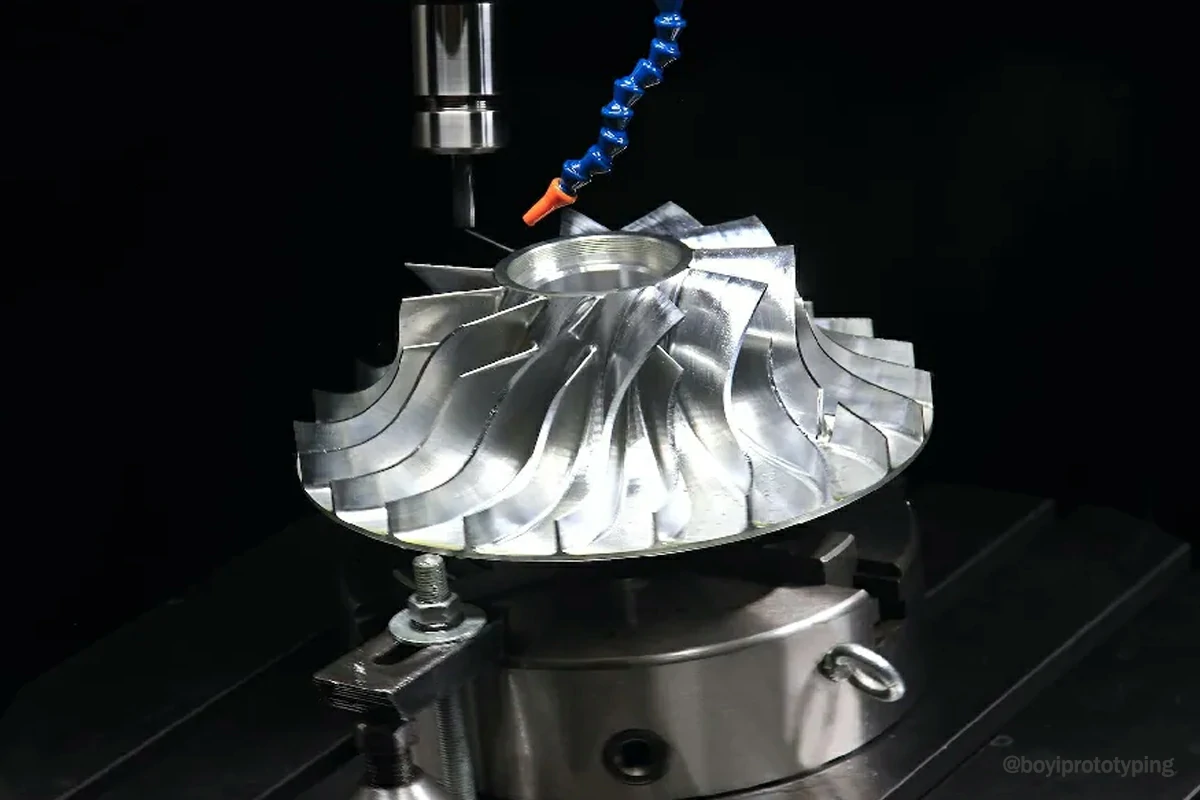

Across sectors from aerospace and medical devices to automotive and energy, manufacturers are leveraging 5-axis CNC machining to meet demanding requirements. Complex geometries – such as contoured knee implant surfaces, impellers, or turbine blades – can be produced in a single setup with high repeatability. This multi-axis flexibility reduces the number of setups and special fixtures needed, significantly streamlining production. The results include smoother surface finishes with less manual polishing, as continuous cutting along five axes minimizes tool vibration and “chatter”.

In short, the consensus from recent technical overviews and industry reports is clear: 5-axis CNC machining offers a broad set of advantages – from precision and complexity na efficiency and cost-effectiveness – that empower manufacturers to tackle the toughest part designs. The sections below explore 10 game-changing benefits of 5-axis CNC machining for precision production. Each section highlights how modern CNC machining – including advanced CNC Milled parts and CNC Turned parts – delivers value. General manufacturers and sourcing managers can apply these insights across fields like automotive, aerospace, medical, machine building, and automotion. For specialized CNC machining service and expertise, partnering with an experienced provider like CNCRUSH (China-based, 12+ years in business) can bring these advantages to your production floor.

CNC Machining Precision: Unmatched Accuracy and Tight Tolerances

One of the most cited benefits of 5-axis CNC machining is its extrémní přesnost. By adding the A and B rotation axes to traditional X, Y, Z motion, a 5-axis machine can orient the cutting tool to reach hidden or angled surfaces. For example, the medical industry routinely demands tolerances within microns for implants and surgical tools; 5-axis CNC machines deliver this unmatched accuracy. According to industry sources, manufacturers using 5-axis CNC machining achieve superior precision because the tool can cut from the optimal angle and maintain continuous contact. This reduces alignment errors common in multi-setup 3-axis processes, so CNC Milled parts and CNC Turned parts come out consistently within spec.

In practice, higher accuracy means fewer scrapped parts and lower inspection costs. As one manufacturing report notes, parts are produced “to higher standards and with greater consistency” using 5-axis than with 3-axis machining. In aerospace or automotive engine components, for instance, every micron of error can affect performance. A CNC machining service using 5-axis mills can often machine an engine housing or a critical aerospace fitting in one go, ensuring concentricity and alignment. This level of precision is difficult or impossible with simpler machines. In summary, 5-axis CNC machining significantly improves accuracy and repeatability, making it ideal for high-precision CNC Milled parts and CNC Turned parts.

CNC Machining Geometry: Enabling Complex Shapes and Design Freedom

A key advantage of advanced CNC machining is the ability to produce highly složité geometrieTradiční 3osé frézy jsou omezeny na pohyby X, Y, Z a nejsou schopny snadno vytvářet podříznutí nebo strmé úhly bez vícenásobných operací. Naproti tomu 5osé CNC obrábění poskytuje designovou svobodu přidáním dvou rotačních os. Řezný nástroj lze naklonit a otočit, aby bylo možné dosáhnout hlubokých dutin, úhlových stěn nebo sochařských povrchů v jedné operaci. Odborníci z průmyslu zdůrazňují, že 5osé stroje mohou „dosáhnout těsných prostor, které jiné metody nemohou přístup“, což umožňuje díly, které byly dříve neobrobitelné.

For example, implantable medical devices (like a knee joint) often have organic, curved surfaces. A 5-axis milling machine can move around the part to smoothly machine both sides of the curve without stopping. Similarly, aerospace components such as turbine blades or complex manifolds with twisted channels can be milled accurately because the tool continuously follows the contour. As one source notes, 5-axis machining “enables the production of complex shapes and contours in a single setup,” expanding what designers can create.

Moreover, 5-axis systems support both milling and turning operations in some configurations, making them versatile for CNC turned parts as well. For instance, a part that combines a turned cylindrical feature with a milled pocket can sometimes be completed on one 5-axis machine. By contrast, a 3-axis machine would require taking the part off, re-fixturing it, and switching to a lathe. In short, 5-axis CNC machining turns design complexity into a cost-saving advantage. It significantly widens the range of features (like undercuts, holes at angles, or tight radius cuts) that can be machined without manual workarounds.

CNC Machining Efficiency: Fewer Setups and Faster Production

Another game-changing benefit of 5-axis CNC machining is operational efficiency. With conventional 3-axis machines, producing a part with multiple faces or angles often requires separate setups: the part is repeatedly re-clamped and machined from different sides. Each setup change adds time, labor, and risk of misalignment. By contrast, a 5-axis CNC machine can orient the workpiece and tool so that most of the part is machined in one continuous operation.

Sources report that 5-axis systems greatly reduce the number of setups needed for complex parts. For example, one breakdown of 5-axis advantages highlights “fewer setups” and the ability to avoid complicated fixtures, because the machine itself rotates the part to the optimal orientation. In practical terms, a part requiring 4 fixtures on a 3-axis machine might need only a single fixture on a 5-axis machine. This streamlining accelerates production and cuts labor costs. In the LinkedIn industry survey, engineers note that fewer setups translate directly to faster cycle times and lower manufacturing costs.

In addition to less fixturing, 5-axis CNC machines can often remove more material per pass. By using shorter, stiffer cutting tools at the proper angle, they achieve higher material removal rates. This means jobs finish sooner: the tool is tangential to the surface, so each pass cuts more efficiently and rapidly (as one source explains, “shorter cycle times and lower costs are possible” with 5-axis). All these factors – reduced setups, better tool orientation, and aggressive cutting – add up to significant throughput gains. Manufacturers and sourcing managers find that 5-axis CNC machining streamlines complex part production, speeding time-to-market for precision parts like aerospace brackets, medical implants, or customized machine parts.

CNC Machining Quality: Superior Surface Finish and Part Consistency

Quality of finish is another major advantage of multi-axis CNC machining. When a 5-axis machine cuts continuously along smooth contours, it can deliver exceptional surface quality straight off the machine. By avoiding multiple re-fixturing, there is less chance of misalignment and tool marks that require manual grinding or polishing. Several sources emphasize that 5-axis machining minimizes vibration and avoids “chatter,” resulting in a smooth, consistent surface. As one technical report notes, by tilting the tool or table, 5-axis systems achieve “far better surface finish” on contoured geometries compared to 3-axis machining.

This benefit is critical for parts where finish quality matters. For example, a medical implant must have flawless contours to be biocompatible. Continuous 5-axis machining ensures there are no uncut slivers or tool marks that could cause stress concentrations. In the automotive and consumer markets, better finish can reduce the need for additional grinding or polishing steps. One analysis of 5-axis advantages explicitly links continuous tool engagement to reducing surface imperfections, which in turn lowers post-processing time. In summary, CNC Machining on 5-axis centers consistently produces superior surface finish and part quality – an advantage that saves time and yields more reliable CNC Milled parts and CNC Turned parts.

CNC Machining Versatility: Wide Range of Materials and Applications

5-axis CNC machining is also praised for its ability to work with many materials and applications. Because the tool can maintain the ideal angle, 5-axis machines can tackle hard materials that challenge conventional setups. For example, medical-grade titanium or high-strength steels used in aerospace can be machined more effectively on a 5-axis center, since the cutter reaches optimal orientation to chip away tough alloys. One source notes that with 5-axis, manufacturers “are capable of handling challenging materials with precision, enabling selection of the ideal material for each application.” This means designers aren’t forced to compromise material properties for manufacturability.

Beyond medical or aerospace alloys, 5-axis systems excel with plastics, composites, and other exotic materials too. In the oil and gas industry, for instance, 5-axis centers machine parts from tough steels or corrosion-resistant alloys (noted in industry reports) because the continuous multi-axis cutting can reach all features without multiple rough cuts. The same flexibility applies in strojírenství and automation (automotion) applications, where complex brackets or robotic components are made from a variety of metals and composites. A versatile CNC machining service can switch between aluminum, stainless steel, PEEK, or carbon fiber parts with minimal reprogramming, thanks to 5-axis.

In practice, this means a single CNC milling machine can produce a wide variety of CNC Milled parts and even some turned parts without changing equipment. For example, a CNC machining service like CNCRUSH can manufacture a medical endoscope component one day and an automotive gear housing the next, simply by changing the CAM program. The ability to handle different materials and part types makes 5-axis CNC machining a universal workhorse for many industries.

CNC Machining in Automotive and Machine-Building Industries

The automotive and heavy machinery sectors are major beneficiaries of 5-axis CNC machining. In automotive manufacturing, for example, 5-axis centers have become standard for engine and transmission parts that require extreme precision. According to industry sources, the adoption of multi-axis machining enabled car makers to produce engines with tighter tolerances and more horsepower. 5-axis machines are routinely used for engine blocks, cylinder heads, drive axles, and even rims, where complex shapes and precise fits are critical. One analysis highlights that components like gearboxes and drive axles – traditionally very time-consuming to machine – can be efficiently completed on a 5-axis center.

Similarly, in machine building and industrial automation (sometimes called automatizace), 5-axis machining is transforming how machinery components are made. Robotics, automated production cells, and custom machinery often involve bespoke parts with intricate geometry. As an example, tooling builders use 5-axis CNC to create custom jigs, robotic end-effectors, and high-precision frames in one pass. The high rigidity and accuracy of modern 5-axis machines fit well with the demands of building automated equipment. In short, manufacturers in automotive and machine-building industries rely on 5-axis CNC machining for parts that must meet tight specifications, whether it’s a safety-critical auto part or a custom assembly fixture.

To illustrate this advantage, consider a robotic arm used in assembly lines. Its mounting flange might have complex pockets and holes at different angles. A 5-axis machining center can produce that flange from one setup, whereas a 3-axis machine would need multiple orientations. By reducing complexity and tooling changes, 5-axis CNC machining lets automotive and machine builders deliver high-quality parts faster. In these sectors, cutting-edge 5-axis CNC Machining not only improves product performance but also accelerates development – exactly what sourcing managers need to stay competitive.

CNC Machining Axis Comparison: 3-Axis, 4-Axis, and 5-Axis Systems

To understand the leap that 5-axis technology represents, it helps to compare it with simpler CNC configurations. A 3-axis mill moves the cutting tool along the X, Y, and Z linear axes and is suitable for prismatic parts or flat surfaces. A 4-axis machine adds one rotary axis (often called A or B), allowing the part to be turned or tilted along one direction. This enables machining on multiple faces (for example, milling around a turned cylinder) without remounting. By contrast, a 5-axis mill has two rotary axes in addition to X, Y, Z, letting the tool approach from virtually any angle.

The table below summarizes the capabilities and applications of 3-, 4-, and 5-axis CNC Machining:

| Aspekt | 3-osé CNC | 4-Axis CNC | 5osý CNC |

|---|---|---|---|

| Degrees of freedom | 3 linear (X, Y, Z) | 4 (X, Y, Z + one rotary axis) | 5 (X, Y, Z + two rotary axes) |

| Typical movement | Tool moves vertically/horiz. | Adds rotation of workpiece or tool; can machine one additional face or continuous profiles around one axis. | Tool and table tilt/rotate; full multi-directional machining. |

| Common applications | Simple prismatic parts, 2½D milling, flat plates | Parts requiring one side milling (e.g., simple cam shafts, stacking operations) | Complex 3D parts: aerospace impellers, turbine blades, sculpted molds, medical implants |

| Setup/Fixturing needs | Multiple setups for multiple sides | Fewer setups than 3-axis; still limited for undercuts | Minimal setups: machines multiple faces/orientations in one setup |

| Precision capability | Good, but multi-fixture errors possible | Improved over 3-axis for some parts | Highest precision for complex geometry |

| Cost (equipment) | Lowest | Mírný | Highest (advanced hardware/software) |

Table: Comparing CNC machining axis capabilities and typical applications

In summary, 5-axis CNC machining offers far greater flexibility than 3- or 4-axis systems. It is especially suited for high-complexity parts where a 3-axis machine would struggle. For example, an aerospace impeller with twisted blades is essentially impossible on 3-axis but straightforward on 5-axis. The table above (derived from industry sources) illustrates that 5-axis systems require higher investment but yield superior capabilities and efficiency.

CNC Machining Automation: The Future of Complex Production

Industry trends show that CNC machining is increasingly integrated with automation (often referred to as automatizace in machine-building contexts) to further boost productivity. Modern 5-axis CNC centers are frequently part of automated manufacturing cells: robots load/unload parts, and smart software optimizes toolpaths. This means facilities can run lights-out for overnight production of precision parts. Research notes that advances in robotics and multiaxis machining have made 5-axis machines “easier to operate and their process more time-efficient,” supporting broader adoption in automated plants.

In an automated workflow, 5-axis machines also enhance flexibility. For example, a single CNC station could alternately produce different CNC milled parts for various assembly lines, without manual changeovers. This fits well with smart factory goals. Moreover, as machine building evolves, 5-axis technology is being embedded into automated machine tools themselves – think of a machining center that self-adjusts to new CAD models. While specific future uses are still emerging, sources agree that the addition of 5-axis capability is “one of the most groundbreaking innovations” for industry.

Put simply, 5-axis CNC machining paves the way for more sophisticated Průmysl 4.0 and automotion solutions. Sourcing managers in sectors like automotive or electronics can rely on 5-axis providers to quickly iterate on designs. For instance, an automotive supplier could use 5-axis machining to prototype a new engine mount overnight, then seamlessly transfer that process to production with minimal human oversight. This synergy of precision CNC Machining and automation drives both quality and agility in manufacturing.

CNC Machining Cost Benefits: Efficiency and Waste Reduction

Though 5-axis CNC machines have a higher upfront cost, they often lower overall production costs in the long run. Two main factors contribute to cost savings: material efficiency and reduced labor. 5-axis centers can cut parts more closely together in the stock material, maximizing utilization. One LinkedIn analysis highlights that tighter tolerances and sophisticated nesting enabled by 5-axis reduce material scrap. In practice, CNC machined parts tend to require less rework or bailing out of defects, so raw material waste is significantly reduced.

Secondly, the time savings translate into cost savings. As noted earlier, single-setup machining and higher cutting speeds shorten cycle times. A shorter job shop time means lower machining overhead per part. Additionally, longer cutting tool life (since 5-axis often uses shorter, more robust tools) cuts tool spending. One report explicitly states that 5-axis machining “eliminates the need for constant tool replacement” and reduces labor costs through automation. Over many parts, these savings add up. For example, in automotive manufacturing, companies found “substantial savings in material costs” and less scrap after adopting 5-axis machining.

Finally, reduced waste and rework have environmental benefits. Less material usage and fewer rejected parts align with lean and green manufacturing goals. In summary, the cost-effectiveness of 5-axis CNC machining makes it attractive: it lowers per-part costs through efficiency gains and waste reduction. Manufacturers and sourcing managers should consider these savings when evaluating CNC machining services for precision projects.

CNC Machining Partnerships: Leveraging Expert Services (CNCRUSH)

With all these advantages in mind, having the right CNC machining partner is crucial. A specialized CNC machining service can maximize the benefits of 5-axis technology. CNCRUSH, for example, is a China-based provider with over 12 years of experience in precision CNC Machining. They offer advanced CNC milling and CNC turning services, producing complex CNC Milled parts and CNC Turned parts to exacting standards. Because CNCRUSH focuses on high-mix, low-volume manufacturing, they routinely use 5-axis centers for medical, automotive, and industrial components.

Partnering with a capable service like CNCRUSH means you get both the machinery and the know-how. Their engineers can optimize toolpaths for complex parts, minimizing setup time and surface defects. If your project involves intricate geometries or tight material specifications, a 5-axis machining service will ensure success. In short, readers in manufacturing and supply chain roles are encouraged to consult CNCRUSH for their precision part needs. With 5-axis CNC Machining capabilities, CNCRUSH can support rapid prototyping through production runs, delivering parts that meet your tolerance, finish, and lead-time requirements.

Table: To help visualize how part complexity influences CNC machine choice, the table below outlines some examples:

| Part/Component Example | Complexity Level | Recommended CNC Setup |

|---|---|---|

| Simple brackets, flat plates | Nízký | 3-Axis CNC Machining (basic) |

| Shafts, cylindrical parts | Střední | 4-Axis CNC Machining (added rotation) |

| Engine manifolds, turbine blades | Vysoký | 5-Axis CNC Machining (full multi-axis) |

| Medical implants (complex shapes) | Vysoký | 5osé CNC obrábění |

This table shows that as part geometry becomes more intricate, moving to 5-axis CNC machining becomes advantageous. For instance, an aerospace impeller or a sophisticated medical implant falls in the “High” complexity category where 5-axis processing excels.

Často kladené otázky (FAQ)

Q: What distinguishes 5-axis CNC machining from 3-axis or 4-axis?

A: A 5-axis machine adds two rotational axes to the standard X, Y, Z axes. This lets the cutting tool approach the workpiece from virtually any direction. As a result, 5-axis machining can handle complex 3D shapes and reduce setups compared to 3- or 4-axis machines.

Q: What are CNC Milled parts vs CNC Turned parts?

A: CNC frézované díly are made by removing material with a rotating cutting tool that moves along multiple axes, while CNC soustružené díly are made on a lathe where the workpiece rotates against a stationary tool. Many parts require both operations. Advanced 5-axis CNC machining can often incorporate turning capability (in 5-axis mill-turn machines) or produce milled features that would otherwise need turning on a lathe.

Q: When is 5-axis CNC Machining worth the investment?

A: 5-axis is most beneficial for parts with complex geometry, tight tolerances, or hard-to-reach features. If you frequently make parts with angled holes, sculpted surfaces, or require high precision and surface finish, 5-axis machines save time and improve quality. Additionally, if reducing setups and fixturing costs is important, 5-axis offers strong advantages.

Q: Can 5-axis CNC machining handle parts for the automotive or machine-building industries?

A: Absolutely. In fact, the automotive industry widely uses 5-axis machining for engine components, transmission parts, and more, achieving tighter tolerances and performance gains. Machine-building and robotics applications also rely on 5-axis machining to produce custom fixtures, housings, and automation parts with complex shapes.

Q: How can I ensure a CNC machining project is successful?

A: Partnering with an experienced CNC machining service is key. Experts can advise on design for manufacturability, select the right machine (3-, 4-, or 5-axis), and optimize tooling. For example, CNCRUSH offers professional CNC machining services (including 5-axis milling) and specializes in delivering high-quality CNC Milled parts and CNC Turned parts. Their team’s deep experience can help translate your design into a precision part efficiently.

Q: What software and skills are involved in 5-axis CNC Machining?

A: 5-axis machining requires advanced CAM software to generate the complex toolpaths and skilled programmers to plan the processes. Operators must understand multi-axis kinematics and collision avoidance. The payoff is machine efficiency and part accuracy. Many service providers have in-house expertise to handle these challenges.

Q: How does automation (automotion) relate to CNC Machining?

A: Automation can enhance CNC machining by integrating robotics and smart tooling. For example, automated part loading/unloading and real-time monitoring allow 5-axis machines to run with minimal human intervention. The term automatizace reflects the synergy of automated systems with precise CNC machining, enabling 24/7 production of CNC milled and turned parts with consistent quality.

Overall, 5-axis CNC machining delivers transformative benefits for precision production. It solves many limitations of traditional machining by combining flexibility, speed, and accuracy. For manufacturing teams looking to optimize complex part manufacturing, leveraging advanced CNC machining – and consulting experts like CNCRUSH – is a strategic move toward higher quality and efficiency.