CNC Milling: Basics of Cutting Speed, Feed Rate, and Depth of Cut for CNC Milled parts

CNC Milling relies on three primary cutting parameters: cutting speed, feed rate, and depth of cut. For a milling cutter of diameter D rotating at N RPM, the cutting speed is Vc=πDN/1000V_c = \pi D N / 1000 (with D in mm and N in RPM). Rychlost posuvu is the distance the cutter advances per time (mm/min or in/min) and is related to chip load per tooth. In milling, feed per tooth f_z multiplies by spindle speed and number of flutes to give the feed rate. Depth of cut is the axial thickness of material removed in one pass (often millimeters).

Adjusting these parameters is critical. Too high a cutting speed causes rapid tool wear, while too low a speed wastes time. Likewise, very high feeds boost productivity but risk poor finish; too low feeds cause rubbing rather than cutting. As American Micro Inc. explains, “Speed and feeds are two of the crucial parameters for precision cutting, and both impact tool longevity, machining speeds and surface finish”. In practice, machinists use speed-and-feed calculators or manufacturer tables to balance these effects.

CNC Milling vs CNC Turning: Key Differences in Cutting Speed for CNC Turned parts

CNC milling and CNC turning differ fundamentally in how they generate cutting speed. In milling (for CNC frézované díly), the tool rotates and the workpiece is clamped. Cutting speed is computed with the cutter’s diameter (D = tool diameter). In turning (for CNC soustružené díly), the workpiece itself spins, so D is the workpiece diameter in the same formula. These differences affect feeds and motions: milling feeds are usually set in units/minute (e.g. mm/min) because many teeth engage continuously, while turning feeds are in mm or inches per revolution (IPR) since one cutting point engages each rev.

| Aspekt | CNC frézování | CNC soustružení |

|---|---|---|

| Speed Formula | Vc=πDtool×RPM/1000V_c = \pi D_{\text{tool}} \times RPM/1000 | Vc=πDpart×RPM/1000V_c = \pi D_{\text{part}} \times RPM/1000 |

| Feed Specification | mm/min (ipm) (multi-flute tool, unit time) | mm/rev (ipr) (single-point tool, per revolution) |

| Tool Engagement | Multiple cutting edges engage consecutively | One cutting edge engages per revolution |

| Typické díly | Flat/contoured parts (automotive housings, molds) | Round parts (shafts, pistons, automotive pins) |

These differences mean that a speed-feeds combination for a milled part often needs re-calibration for turning, and vice versa. For example, a constant surface speed setting (G96) on a lathe will automatically reduce RPM as diameter shrinks, whereas on a mill the programmer sets RPM and feed directly. In milling, small cutter engagements can cause chip thinning (see below), whereas turning can suffer from vibration if RPM is too high for a slender bar.

CNC Milling Materials: Hardness and Cutting Speed for CNC Milled parts

Material properties heavily influence cutting speeds. Tvrdost in particular dictates how fast you can cut. “the softer the work material, the faster the recommended cutting speed” a “the harder the material, the slower the cutting speed”. For instance, common aluminum alloys often tolerate 300–400 m/min surface speed, while stainless steels or tool steels are often limited to 50–150 m/min. Aluminum alloys ~300–400 m/min vs. high-nickel alloys (Inconel) around 5–10 m/min. In general, machining steel (including many machine-building parts) uses lower speeds than machining aluminum (common in automotive castings).

Cutting speed also depends on the cutter material. Carbide and ceramic cutters can run at much higher speeds than high-speed steel (HSS). The harder the cutting tool material, the faster the cutting speed. For example, a carbide end mill might run 2× faster (or more) than an equivalent HSS tool in the same workpiece. When planning a cut, machinists consult material-species speed charts (surface feet/min or m/min) and then adjust feed and depth accordingly. In short: use higher speeds for soft materials and hard tools; slow down for tough materials or less-rigid setups.

CNC Milling and Tool Material: Speed Considerations for CNC Turned parts

The tool’s composition and geometry also set speed limits. Harder, wear-resistant tools permit higher speeds: polycrystalline diamond (PCD) or cubic-boron nitride (CBN) inserts excel at high-SFM cutting of non-ferrous or abrasive materials. In contrast, softer tools like HSS suffer rapid wear at high heat. For higher cutting speeds, tools made of high-strength materials like diamond and boron nitride can be used; for lower cutting speeds, high-speed steel is suitable. In practice, a machinist choosing tooling for CNC milling parts of aluminum might pick carbide and run at top RPM; for steel, they might use tougher steel or cermet at more moderate RPM.

These principles apply equally to turning. A carbide lathe insert will allow faster SFM than an HSS tool. Higher speeds generate more heat, so tool coatings (TiN, TiAlN, etc.) are often used to extend tool life. It’s common in manufacturing to reduce speed if the tool starts to smoke or chatter. As one machinist explains, “Tools with a fixed diameter need to be programmed to that one RPM that brings them to the speed they need to be at for that material… on a lathe you will likely see speed in SFM and feed in IPR.” In short, always consider tool hardness and cutter diameter when setting speeds for both milled and turned parts.

CNC Milling: Chip Thinning, Feed Rate, and CNC Milled parts

In milling, ředění třísek is a common phenomenon when making shallow side cuts. If the radial depth of cut (width) is less than about half the cutter’s diameter, the chip becomes thinner than the programmed feed per tooth. This reduces material removal per tooth and can lead to rubbing. For example, if you cut with only 25% engagement of a cutter, each tooth takes a much lighter chip. The solution is to increase the programmed feed (or overlap passes) to maintain effective chip thickness. Chip thinning “reduces chip load (the amount of material removed during one revolution)… resulting in longer lead times.

Any cut width less than half the diameter causes chip thinning… increasing the feed rate will help mitigate [chip thinning], increase productivity, and extend the tool’s lifespan.”. In effect, feeding faster (or lowering RPM) under these conditions restores the intended chip thickness. High feed rates with multiple passes are often preferred over one heavy pass, as they keep the cutter engaged and maintain speed. In practice, machinists monitor chip size visually: a very thin or powdery chip signals that feed should be raised or cutting width increased.

Adjusting cutting speed can also help with chip thinning. Running the tool at a somewhat higher speed (while keeping chip load constant) can improve shearing and reduce the tendency for chips to tear. However, this must be balanced against heat buildup. Overall, understanding chip thinning is critical in CNC milling with small features or multiple passes.

CNC Milling: Depth of Cut vs Cutting Speed in CNC Turned parts

Depth of cut (axial engagement) and cutting speed must be balanced. In general, “deeper cuts [remove] more material, increasing the load on the tool and increasing heat. To compensate, reduce cutting speed,” . In practical terms, a very heavy cut (deep slot or roughing pass) usually requires slowing the spindle to avoid breaking the tool. Conversely, finishing passes with minimal depth of cut can often run at much higher speeds.

This principle applies to turning as well. On a lathe (CNC soustružené díly), a heavy roughing pass on a large diameter will need lower SFM, whereas a light finishing pass on a smaller diameter can use higher SFM (if the machine allows). For example, if you bore a 0.5″ deep cut versus a 0.1″ cut, you might drop speed by 20–30% on the deeper cut. Many CAM systems and machinists use “speed multipliers” for different pass types. The key insight is: depth of cut and cutting speed are interlinked. There is no one-size-fits-all: the ideal speed depends on depth of cut, tool, material, and desired surface finish.

CNC Milling: Optimizing Cutting Speed for CNC Milled parts Quality

Optimal cutting speed maximizes efficiency without sacrificing quality. Spindle speed and feed rate impact tool longevity, machining speeds and surface finish. Too low a speed or feed wastes machine time; too high risks tool failure. For precision CNC millingparts, finding the sweet spot is essential. For instance, when CNC milling a fine surface feature, a slightly slower feed (say 50% chip load) can yield a mirror finish, while allowing a higher RPM (surface speed) can complete the cut quickly without overheating.

Surface finish is particularly sensitive to these settings. Cutting speed itself “doesn’t have any role in deviating the chip direction” or scallop marks; instead, feed rate sets the scallop height on the part. Thus, a high spindle speed with a fine feed is a common strategy for a smooth finish. However, speed cannot be increased indefinitely: higher RPM increases vibration and chatter, especially with long end mills. Machinists often perform “test cuts” or rely on tooling guides to dial in the best speed for the given tool and depth. In summary, optimizing cutting speed is about balancing material removal rate with tool life and surface requirements.

CNC Milling vs CNC Turning: Tool Life and Heat in CNC Turned parts

Cutting speed is the dominant factor affecting heat and tool wear. Higher cutting temperatures can severely shorten tool life, while feed rate has a lesser effect. In CNC soustružené díly, this is especially true: a small error in SFM on a hard material can cause tool failure. For example, if a lathe tries to maintain a constant SFM (G96) on a diameter that shrinks below machine limits, the spindle may hit max RPM and “tear” the cut instead of cleanly shearing it.

Harder materials (like Inconel or titanium) have a smaller margin for speed and feed errors. In practice, machinists often reduce speed significantly when encountering unusual tool wear or burn. Conversely, for softer materials (aluminum, plastics), there is more tolerance for aggressive speeds. The key takeaway is: high cutting speed → high heat → faster wear. In a production setting (automotive shafts, for example), tools are routinely changed or recoated once wear exceeds a threshold, which often correlates to the chosen SFM. CNC milling machines mitigate this through coolant, but lathe (turning) operations can still see rapid wear if speeds are too high.

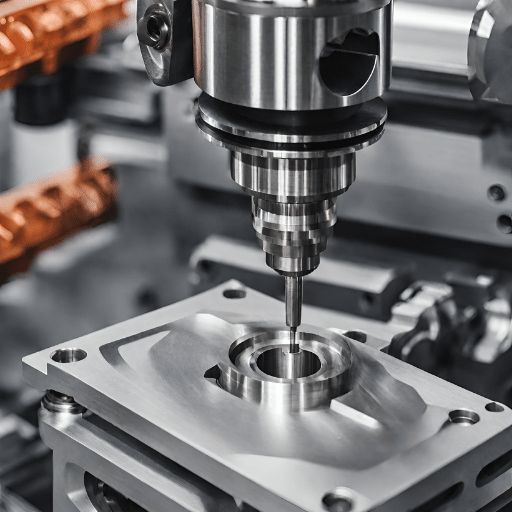

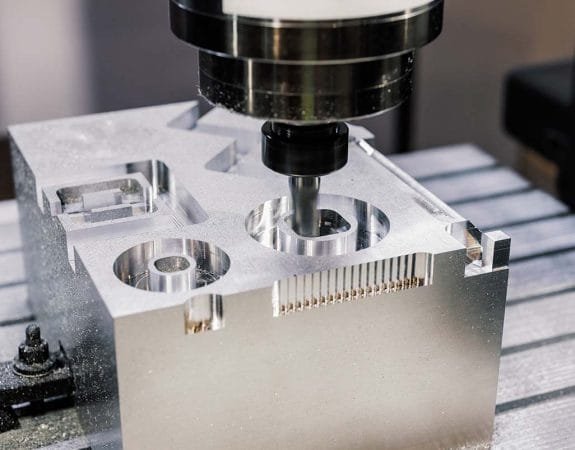

CNC Milling in Industry: Automotive, Machine Building, and CNC Milled parts

CNC milling is ubiquitous in industries like automotive, aerospace, machine building, and general automation. In these sectors, part tolerances are tight and even small surface defects can be critical. For example, engine brackets or transmission housings (CNC milling parts) must meet exact specifications to function reliably. CNC milling is used for manufacturing parts for industries like automotive… the slightest error or flaw in the components can have a significant impact on [their] reliability and even safety.

Machine-building companies similarly rely on CNC milling parts for frames, gears, and tooling components. Cutting speed choices here often balance productivity and cost: steel structural parts may be cut at moderate speeds to extend cutter life, while non-critical components can be rough-machined at higher feeds. Notably, many European and U.S. manufacturers now adopt high-speed milling (trochoidal cutting, dynamic milling) to increase throughput, which involves extremely high RPM and low depth of cut. These advanced strategies still follow the same speed/feed principles outlined above. For those needing large-volume or complex CNC milled parts, specialized CNC machining services (like CNCRUSH, with 12+ years in precision machining) supply high-quality parts for the global automotive and machine-building markets.

CNC Milling: Balancing Speed and Feed in CNC Turned parts

Ultimately, CNC machining is a compromise. Spindle speed (RPM) and feed rate work together to produce each chip. Running at too low a speed with too high a feed can overload the tool; too high a speed with too low a feed can cause rubbing. In both milling and turning, machinists often rely on recipes: start with manufacturer recommendations (chip load per tooth and SFM) and then fine-tune. Computer software (like feed/speed calculators or CAM simulation) is frequently used to optimize efficiency and avoid trial-and-error.

For example, increasing feed increases material removed per time but also heat and cutting force. Some machinists employ variable-speed strategies (like constant surface speed on lathes) to balance this as diameters change. The key rule is to never exceed machine or tool limits: if either the feedrate or RPM hits the maximum allowed (e.g., the machine’s gearbox limit), then adjust the other parameter. In practice, experts will often set speeds for tool life (often slower) and adjust feeds for cycle time (often higher) until the machine or tool is the bottleneck. This balance of speed and feed is what delivers precision CNC milling parts a CNC soustružení dílů efficiently and economically.

FAQ

Q: What is the difference between cutting speed and feed rate?

A: Cutting speed (Vc) is the linear speed of the cutting tool’s edge against the workpiece surface (often ft/min or m/min). Feed rate is the distance the tool advances per spindle revolution or per minute (mm/rev or mm/min). In simple terms, rychlost dictates how fast the material moves past the cutter, while feed dictates how much material is engaged per pass. Speed mainly affects heat and tool life, while feed affects machining time and surface roughness.

Q: How does cutting speed affect tool life?

A: Higher cutting speeds generate more heat and friction, which accelerates tool wear and shortens tool life. A tool cutting at double the speed might wear out several times faster. Cutting speed is a primary driver of cutting temperature; a high speed on a hard material can cause rapid wear or even burning. Conversely, reducing speed prolongs tool life but reduces productivity. The optimal speed is often a trade-off guided by tool manufacturer data.

Q: Why is chip thinning important in CNC milling?

A: Chip thinning occurs when the radial cut is shallow (less than half the cutter diameter). In that case, the chip thickness is less than the feed per tooth, so each tooth removes less material than intended. This can lead to rubbing and inefficiency. To compensate, the feed per tooth of cnc milling should be increased or overlapping passes used. As discussed above, raising the feed rate under chip-thinning conditions restores proper chip thickness and improves tool life.

Q: How do I choose cutting speed for different materials?

A: Consult material-specific speed charts (often given in SFM or m/min). Softer materials like aluminum can be cut at higher speeds (hundreds of m/min), while steels and nickel alloys need much lower speeds. For example, aluminum (~300–400 m/min), mild steel (~100 m/min), and titanium (~20–60 m/min) are typical guidelines. Then adjust feed and depth for the tool and setup. Tool material also matters: with carbide cutters you might double these speeds versus an HSS tool.

Q: What industries use CNC milling and turning?

A: Nearly every manufacturing industry uses CNC machining. Automobilový průmysl a strojírenství are especially prominent. Cars, trucks, and construction machines have countless milled and turned metal parts, from engine blocks to hydraulic valves. Aerospace, medical, electronics, and defense also use CNC milled parts for high-precision components. In all these fields, small mistakes can be very costly, which is why companies trust experienced CNC machining service providers (such as CNCRUSH) to deliver precise CNC frézované díly a CNC soustružené díly reliably.