CNC Machining is the backbone of modern aerospace manufacturing, providing critical capabilities to produce high-performance components with micron-level accuracy, shortened lead times, and optimized costs. Below is an in-depth analysis of 10 stærke måder CNC Machining understøtter rumfartsindustrien, komplet med rig teknisk indsigt, procesdiskussioner og perspektiver på tværs af sektorer. CCRRUSH—a China-based factory with 12 years of expertise in CNC Machining Service, med speciale i CNC fræsede dele og CNC drejede dele—stands ready to meet your most demanding aerospace, automotive, machine building and automotion needs.

1. CNC-bearbejdningsservice: Præcisionsekspertise for CNC-fræsede dele

Modern aerospace brackets, ribs, and housings demand surface finishes finer than Ra 0.8 µm and dimensional tolerances down to ±0.005 mm. Our CNC machining service leverages simultaneous multi-axis control to mill free-form contours in one setup, eliminating cumulative errors from multiple fixtures. By optimizing tool paths for constant cutter engagement, we reduce deflection and thermal growth, ensuring consistent part quality across high-volume runs. This level of precision is critical til bærende komponenter i flyskrog, der udholder vibrationer, termisk cykling og udmattelse. Uanset om vi bearbejder aluminiumslegeringer for at spare vægt eller hårdere nikkellegeringer til højtemperaturzoner, blander vores tilgang til CNC-fræsede dele avancerede CAM-strategier, værktøj med høj stivhed og spindelkompensation i realtid - og leverer den repeterbarhed og overfladeintegritet, som rumfartsingeniører kræver.

2. CNC Machining Service: Quality Enhancement for CNC Turned Parts

Landing gear cylinders, actuator rods, and spline shafts require concentricity within ±0.002 mm and surface roughness below Ra 0.4 µm. Integrating live-tool turning with multi-axis machining allows us to produce complex CNC turned parts—including cross-drilling, polygon milling, and undercuts—in a single fixture. Synchronized spindle and rotary table movements optimize chip evacuation and coolant flow, preserving metallurgical integrity when processing titanium and stainless steel alloys. This unified workflow cuts scrap rates by up to 60% and slashes secondary operations, delivering positive cost impacts. With automated tool-life monitoring and adaptive feed adjustments, our CNC machining service ensures each turned component meets the tightest aerospace standards without compromise.

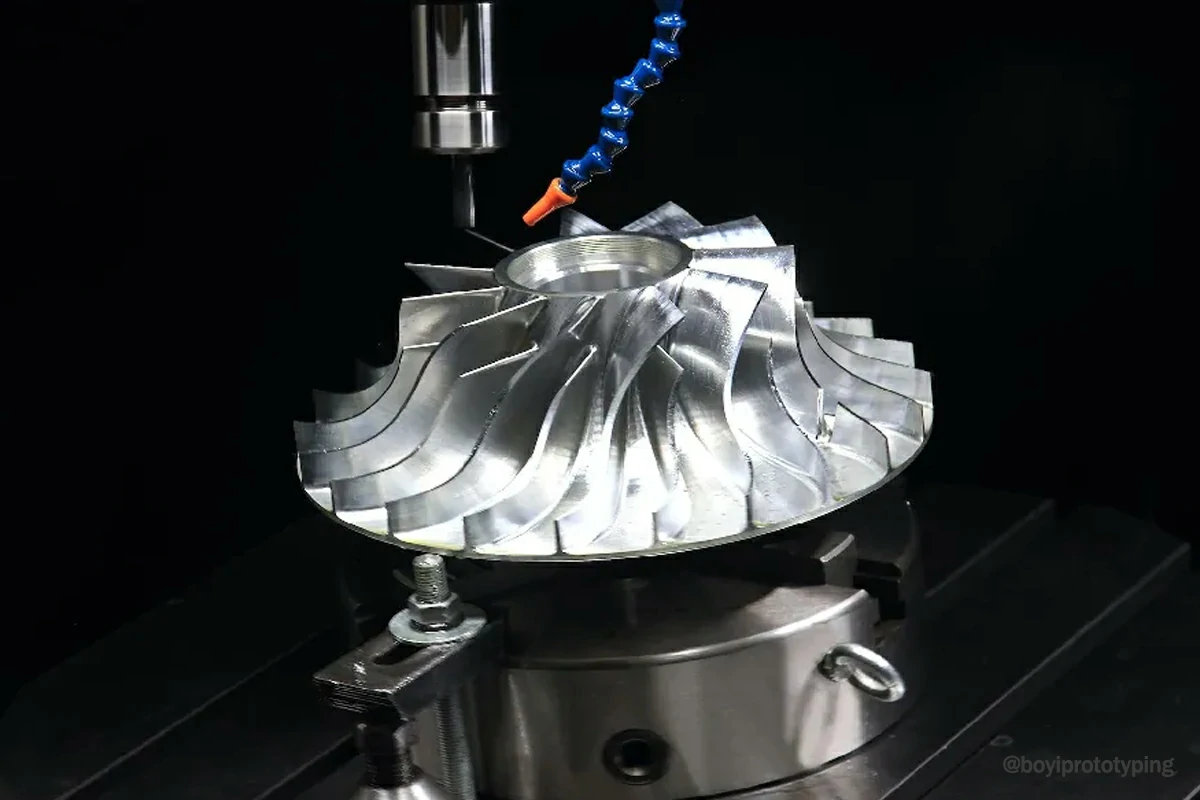

3. CNC Machining for Complex Turbine Blade Manufacturing

Turbine blades blend aerodynamic finesse with internal cooling channels, featuring compound curves and deep pockets. Conventional 3-axis mills struggle to access these features without extensive manual setups. Our 5-axis CNC machining centers approach every blade surface in one clamp, enabling precision pocketing of cooling passages and final polishing of aerofoil profiles. Advanced tool-path algorithms adjust tilt angles to maintain optimal cutter contact, reducing wear on expensive carbide and CBN inserts. The result is an extended tool life, smoother blade finishes, and consistent aerodynamic performance. This capability transforms turbine production from a multi-operation chore into a streamlined, high-precision process—boosting engine efficiency and reliability.

4. CNC-bearbejdningsservice: Hurtig prototyping og CNC-fræsede dele Leveringstider

In aerospace R&D, time is of the essence. CNCRUSH’s CNC machining service uses zero-point clamping and quick-change pallet systems to reduce non-machining time by over 50%. Engineers receive true-to-CAD CNC milled parts—such as avionics brackets and sensor housings—within days, not weeks. Our workflow integrates digital job tickets, automated nesting, and real-time production monitoring, so you can iterate designs rapidly without sacrificing accuracy. This agility is vital for validating form-fit-function on critical flight systems and accelerates the transition from prototyping to qualification testing, keeping development schedules on track.

5. CNC Machining Service: Advanced Materials for CNC Milled Parts

Aerospace applications increasingly rely on difficult-to-machine alloys like Ti6Al4V, Inconel 718, and carbon-fiber composites for their strength-to-weight benefits. These challenging materials work-harden rapidly and demand precise thermal control. Our CNC machining service employs high-pressure through-spindle coolant, ceramic-coated carbide inserts, and rest-machining strategies to maintain cutting temperatures below critical thresholds. Combined with dynamic tool-path smoothing, we prevent chatter and delamination while achieving fine surface finishes. The result is CNC milled parts that meet or exceed mechanical and fatigue life requirements, enabling designers to push performance envelopes confidently.

6. CNC Machining Service: Automation in CNC Turned Parts Production

For at understøtte høj-mix, lav-volumen fly- og bilindustrien integrerer CNCRUSH robot-loading/unloading, laser-måling i processen og automatiske værktøjsskiftere i vores CNC-bearbejdningsservice. Telemetri i realtid om spindelbelastning, vibrationer og værktøjsslid føder adaptive kontrolsystemer, der optimerer tilspændingshastigheder og spindelhastigheder i farten. Denne grad af automatisering sikrer ensartet kvalitet for både CNC-fræsede og CNC-drejede emner døgnet rundt, hvilket drastisk forbedrer gennemløbstiden og reducerer menneskelige fejl. Operatørerne skifter fra manuel indgriben til overvågning af arbejdsgange og tilføjer teknisk værdi i stedet for at overvåge maskiner.

7. CNC-bearbejdningsservice: Omkostningsoptimering for CNC-fræsede dele og CNC-drejede dele

By consolidating milling and turning into unified cell configurations and reducing fixturing steps by up to 80%, our CNC machining service cuts labor and overhead costs significantly. Material nesting algorithms maximize stock utilization, while predictive maintenance scheduling minimizes unplanned downtime. This holistic approach delivers a positive return on investment—even for small-batch aerospace contracts—while ensuring AS9100-level process control. Clients benefit from transparent cost breakdowns, competitive unit pricing, and the ability to scale without capital-intensive infrastructure expansions.

8. CNC Machining Service: Scalability Across Automotive, Machine Building and Automotion

Selv om rumfart kræver den højeste præcision, kan de samme arbejdsgange for CNC-bearbejdningsservice problemfrit anvendes til motorkomponenter til biler, gearkassehuse og værktøj til industriel automatisering. CNCRUSH udnytter ekspertise på tværs af sektorer til at afskrive investeringer i opspænding og programmering, hvilket giver besparelser til kunder på både højvolumen- og nichemarkeder. Vores anlæg håndterer partier fra en enkelt prototype til 10.000 stykker og opretholder ensartede leveringstider og kvalitetsmålinger. Denne skalerbarhed i CNC-fræsede dele og CNC-drejede dele sikrer, at du oplever den samme pålidelighed og omkostningseffektivitet, uanset om du bygger et næste generations fly eller en robot-endeeffektor.

9. CNC Machining Service: Metrology and Quality Assurance

Every part we machine undergoes in-process inspection via integrated CMM probes and laser scanners. Dimensional data is captured in real time, feeding back to the CNC controller for adaptive corrections. This closed-loop metrology ensures that each feature—hole position, surface contour, thread form—stays within specified tolerances without manual post-inspection. Digital inspection reports are delivered with each batch, supporting traceability and regulatory compliance. The result is an unwavering commitment to quality across CNC Milled parts and CNC Turned parts, backed by data-driven assurance.

10. CNC Machining Service: Sustainable Practices in Aerospace Manufacturing

Miljømæssig ansvarlighed er kernen i vores CNC-bearbejdningsservice. Optimerede værktøjsbaner reducerer luftskærende bevægelser med op til 30%, hvilket sænker energiforbruget pr. emne. Vi genbruger hårdmetalværktøj og anvender biologisk nedbrydelige, vandbaserede kølemidler for at minimere den økologiske påvirkning. Derudover identificerer realtidsovervågning muligheder for at konsolidere opsætninger eller samle lignende job, hvilket yderligere reducerer strømforbruget. Denne bæredygtige praksis er i tråd med grønne produktionsinitiativer inden for rumfart og andre områder og viser, at præcisionsteknik og miljøforvaltning kan gå hånd i hånd.

Table 1: CNC Machining Process Comparison

| Aspekt | Konventionel CNC | Advanced Multi-Axis CNC |

|---|---|---|

| Setup Count | 3-5 separate operationer | 1 enkelt opsætning |

| Typisk tolerance | ±0,01 mm | ±0,001 mm |

| Prototype Lead Time | Weeks | Days |

| Materialekapacitet | Aluminium, stål | Titanium, Inconel, kompositter |

| Automationsintegration | Begrænset | Full IoT & Robotics |

Table 2: Material-Process Recommendations

| Materiale | Anbefalet proces | Nøglefordel |

|---|---|---|

| Aluminiumslegeringer | 3-akset og 5-akset fræsning | Fast removal, excellent surface finish |

| Titanium legeringer | 5-Axis High-Speed Milling | Kontrolleret varme, forlænget værktøjslevetid |

| Nikkel-baserede superlegeringer | 5-Axis Rest Machining | Reduced work-hardening, high integrity |

| Kulfiber-kompositter | 5-Axis Specialized Milling | Minimal delamination, precise contours |

| Hærdet stål | Live-Tool Turning & Milling | Tæt rundløb, fin overfladefinish |

FAQ

Q1: Why is CNC Machining essential for aerospace manufacturing?

CNC-bearbejdning leverer præcision på mikroniveau, mulighed for kompleks geometri i en enkelt opsætning og alsidighed i materialer - krav, der er critical for turbine blades, landing gear, and hydraulic components.

Q2: What services does CNCRUSH provide?

CNCRUSH offers turnkey CNC Machining Service, specializing in high-precision CNC fræsede dele og CNC drejede deleog understøttes af AS9100-overholdelse og 12 års brancheerfaring.

Q3: Can CNCRUSH handle both prototypes and production batches?

Yes—our automated workflows and quick-change tooling deliver finished CNC Milled parts in days for prototypes and scale to 10,000 pcs for production volumes with the same precision.

Q4: Hvilke brancher har gavn af CNCRUSH's CNC-bearbejdningsservice?

Beyond aerospace, sectors such as automotive, machine building and automotion, medical devices, and electronics leverage our capabilities for complex, high-precision parts.

Q5: How do I start a project with CNCRUSH?

Request a quote via our inquiry form; our engineering team will optimize your design for manufacturability and recommend the ideal CNC Machining workflow.