The advancement of 5-axis CNC machining has revolutionized the manufacturing of intricate components across various industries, including bilindustrien, maskinbygning, og automatisering. When compared to traditional 3-axis machines, 5-axis CNC systems bring significant improvements in terms of precision, efficiency, and flexibility. It is especially beneficial in industries where quality and accuracy are paramount. As a China-based CNC machining service provider with 12 års erfaring, CNCRUSH specializes in CNC fræsede dele og CNC drejede dele, der tilbyder top-notch produktionsløsninger til globale kunder. Nedenfor vil vi udforske de vigtigste fordele ved 5-akset CNC-behandling for komplekse dele, hvor vi kombinerer indsigt fra forskellige brancheartikler og CNCRUSH's ekspertise.

1. Hvad er 5-akset CNC-bearbejdning?

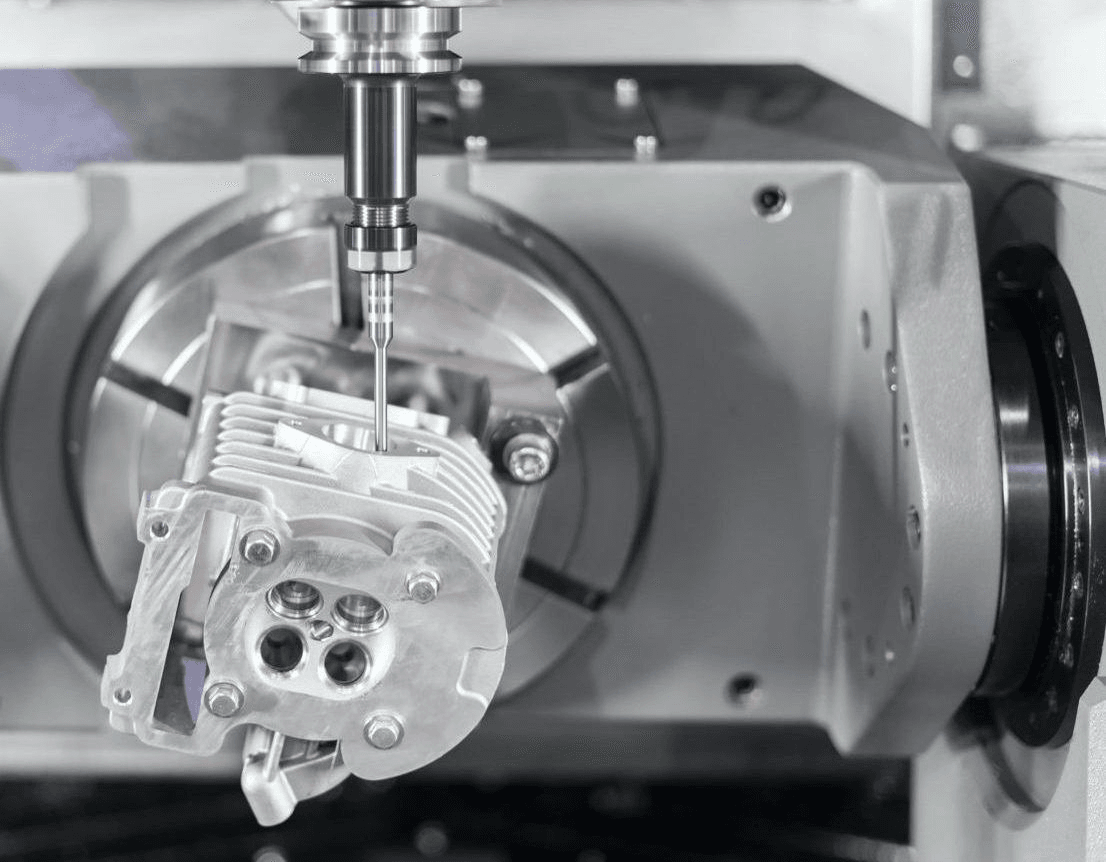

5-axis CNC machining refers to a machining process where the cutting tool moves along five different axes, enabling a higher degree of precision and complexity. Traditional 3-axis machines move along the X, Y, and Z axes, which limit the angles and depth a tool can access. However, with 5-axis CNC machines, two additional axes, the A-axis (tilting) and B-axis (rotational), enable the tool or workpiece to be machined from multiple angles in one setup.

This capability is vital for fabricating complex parts in industries like bilindustrien og maskinbygninghvor buede overflader, flere vinkler og indviklede detaljer er almindelige. For CNCRUSH’s CNC-bearbejdningsservice, this flexibility allows us to reduce production time and ensure higher accuracy, making it ideal for producing CNC fræsede dele og CNC drejede dele for a wide range of applications.

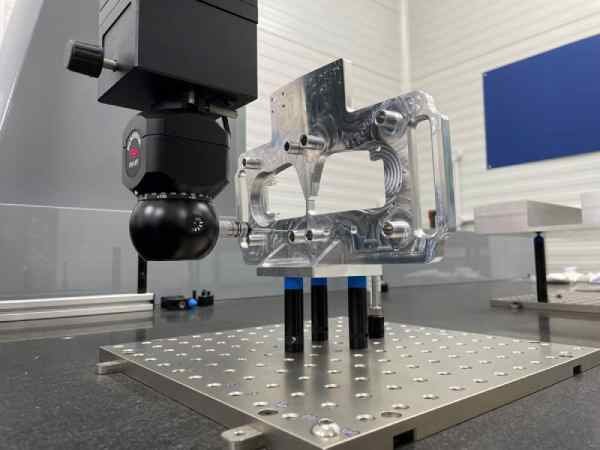

2. Higher Precision and Accuracy

Precision is critical in industries like bilindustrien og rumfart, where every millimeter counts. The primary advantage of 5-axis CNC machining is its ability to achieve tight tolerances and eliminate errors due to repositioning. By machining a part in one setup, 5-axis machines reduce human error and guarantee higher accuracy.

For CNCRUSH, providing high-precision CNC machining services is a core strength. Our experience in fabricating CNC fræsede dele ensures that each part meets the stringent quality requirements of our global clients, whether in maskinbygning, automotion, or other industries.

3. Faster Production and Reduced Setup Times

In traditional 3-axis machining, operators often need to reposition a part multiple times to machine it from different angles, leading to longer setup times. However, with 5-axis CNC machines, multiple sides of a workpiece can be machined in one go, significantly reducing the time spent on setups and allowing for faster production cycles.

For instance, when producing CNC drejede dele, 5-axis technology eliminates the need for multiple setups, resulting in shorter lead times. CNCRUSH leverages this efficiency to deliver high-quality parts on tight deadlines, making us a reliable partner for clients seeking fast, accurate CNC-bearbejdning.

4. Ability to Produce Complex Geometries

One of the key strengths of 5-axis machining is its ability to machine parts with complex geometries that would be difficult, if not impossible, to achieve with 3-axis systems. Components with intricate curves, unusual shapes, or multiple angles can be easily fabricated using 5-axis CNC machining, making it ideal for industries that require highly specialized parts, such as bilindustrien, medicinsk, og rumfart.

For CNCRUSH, producing CNC fræsede dele with intricate designs is a specialty. Our 5-axis capabilities allow us to manufacture components with complex features while maintaining high accuracy and surface finish.

5. Better Surface Finishes

A smoother surface finish is critical for parts that need to meet high aesthetic or functional standards. With 5-axis CNC machines, shorter cutting tools can be used, which reduces vibration and improves the quality of the surface finish. This is particularly important in applications where components require fine detailing or polishing.

For CNCRUSH, this means we can deliver CNC drejede dele with premium surface finishes, minimizing the need for post-machining processes like sanding or polishing. This results in parts that are ready for immediate use in demanding industries like bilindustrien og medicinsk.

6. Cost-Effectiveness and Reduced Tool Wear

Although 5-axis CNC machines are more expensive to purchase and maintain than their 3-axis counterparts, they are more cost-effective in the long run due to reduced setup times, faster production cycles, and lower tool wear. By using shorter cutting tools, 5-axis machines decrease tool deflection, which extends the life of the tool and improves machining accuracy.

At CNCRUSH, we pass these cost savings on to our clients, providing affordable yet high-quality CNC-bearbejdning. Our expertise in using 5-axis technology ensures that we can offer competitive pricing without sacrificing the precision and quality of our CNC fræsede dele og CNC drejede dele.

7. Applications in Key Industries

5-axis CNC machining is used across a wide range of industries, including:

- Automotive: Producing engine components, transmission parts, and custom-designed car parts with complex geometries.

- Luftfart: Fabricating turbine blades, airframe components, and other parts requiring tight tolerances.

- Medicinsk: Manufacturing surgical instruments, implants, and devices with high precision.

- Energy: Producing parts for wind turbines and oil and gas equipment that require complex machining.

CNCRUSH has a deep understanding of these industry needs, and our 12 års erfaring allow us to deliver customized CNC-bearbejdning for complex parts in various sectors, ensuring top-tier quality and reliability.

8. Improved Drilling Capabilities

5-axis CNC machines can drill holes at precise angles that are difficult to achieve with 3-axis systems. This capability is essential for parts that require angled holes or slots, such as those used in maskinbygning eller bilindustrien applikationer.

For CNCRUSH, this means we can offer CNC fræsede dele og CNC drejede dele with highly accurate drilling patterns, meeting the specific requirements of industries like bilindustrien og automatisering.

9. Greater Flexibility and Customization

Alsidigheden af 5-akser CNC-maskiner giver producenter mulighed for at fremstille meget tilpassede dele. Denne fleksibilitet er afgørende for kunder, der har brug for dele med unikke specifikationer eller kræver små produktionskørsler. Uanset om det er prototypning eller lavvolumenproduktion, kan 5-akser bearbejdning håndtere kompleksiteten med lethed.

Hos CNCRUSH er vi specialiseret i tilpassede CNC-løsninger, tilbyder skræddersyet CNC-bearbejdning der opfylder vores kunders unikke behov. Vores 5-akse muligheder sikrer, at selv de mest komplekse designs kan bringes til live med præcision og hastighed.

10. Fremtidssikre din fremstillingsproces

Efterhånden som industrierne udvikler sig, vil efterspørgslen efter mere komplekse, præcise og effektive produktionsløsninger kun vokse. Investering i 5-akset CNC-bearbejdning sikrer, at dine produktionskapaciteter forbliver konkurrencedygtige og klar til fremtidens udfordringer. Uanset om du producerer dele til bilindustrien industri eller højpræcisionskomponenter til medicinsk enheder, 5-akset bearbejdning er teknologien, der vil hjælpe dig med at være på forkant.

CNCRUSH er forpligtet til at forblive på forkant med CNC-teknologi. Ved at tilbyde banebrydende CNC-bearbejdning, hjælper vi vores kunder med at fremtidssikre deres drift og sikre, at de kan opfylde kravene fra et marked i konstant forandring.

Tabel: Sammenligning af 3-akset vs. 5-akset CNC-bearbejdning

| Feature | 3-akset bearbejdning | 5-akset bearbejdning |

|---|---|---|

| Antal økser | 3 (X, Y, Z) | 5 (X, Y, Z, A, B) |

| Opsætningstid | Længere på grund af flere opsætninger | Kortere på grund af enkelt opsætning |

| Præcision | Sænke | Højere |

| Evne til at håndtere komplekse dele | Begrænset | Fremragende |

| Overfladefinish | Gennemsnit | Overlegen |

FAQ: Almindelige spørgsmål om 5-akset CNC-bearbejdning

Q: Hvad er de vigtigste fordele ved 5-akset CNC-bearbejdning til komplekse dele?

A: 5-akset CNC-bearbejdning giver højere præcision, hurtigere produktionstider, bedre overfladefinish og evnen til at skabe komplekse geometrier, der er vanskelige eller umulige med 3-akse systemer.

Q: Hvordan forbedrer 5-akset CNC-bearbejdning produktionshastigheden?

A: Ved at tillade dele at blive bearbejdet fra flere vinkler i én opsætning, reducerer 5-akset CNC-bearbejdning behovet for ompositionering, hvilket fører til hurtigere produktionscyklusser og kortere gennemløbstider.

Spørgsmål: Hvilke industrier har mest gavn af 5-akset CNC-bearbejdning?

A: Industrier som f.eks bilindustrien, rumfart, medicinsk, og energi drage stor fordel af 5-akset CNC-bearbejdning på grund af dens evne til at producere meget præcise, komplekse komponenter.

Som konklusion er 5-akset CNC-behandling en banebrydende teknologi til fremstilling af komplekse dele med større effektivitet, nøjagtighed og overfladekvalitet. CNCRUSH's ekspertise på dette område, kombineret med vores avancerede teknologi, CNC-bearbejdning, gør os til den ideelle partner for virksomheder, der søger CNC fræsede dele, CNC drejede dele, og skræddersyede løsninger skræddersyet til deres specifikke behov.