CNC megmunkálás is pivotal in the aerospace industry, where precision, reliability, and performance are non-negotiable. Drawing insights from industry-leading resources, this article delves into the top 10 challenges in CNC machining for aerospace components and presents effective solutions. For over 12 years, CNCRUSH, a China-based factory, has specialized in providing high-quality CNC machining services, including CNC Milled parts and CNC Turned parts, catering to industries such as automotive, machine building, and automation.

Aerospace components demand exceptionally tight tolerances, often within microns, to ensure optimal performance and safety. Achieving such precision requires advanced CNC machining techniques and meticulous quality control.

Megoldás: Implementing high-precision CNC machines and rigorous inspection protocols ensures components meet stringent aerospace standards.

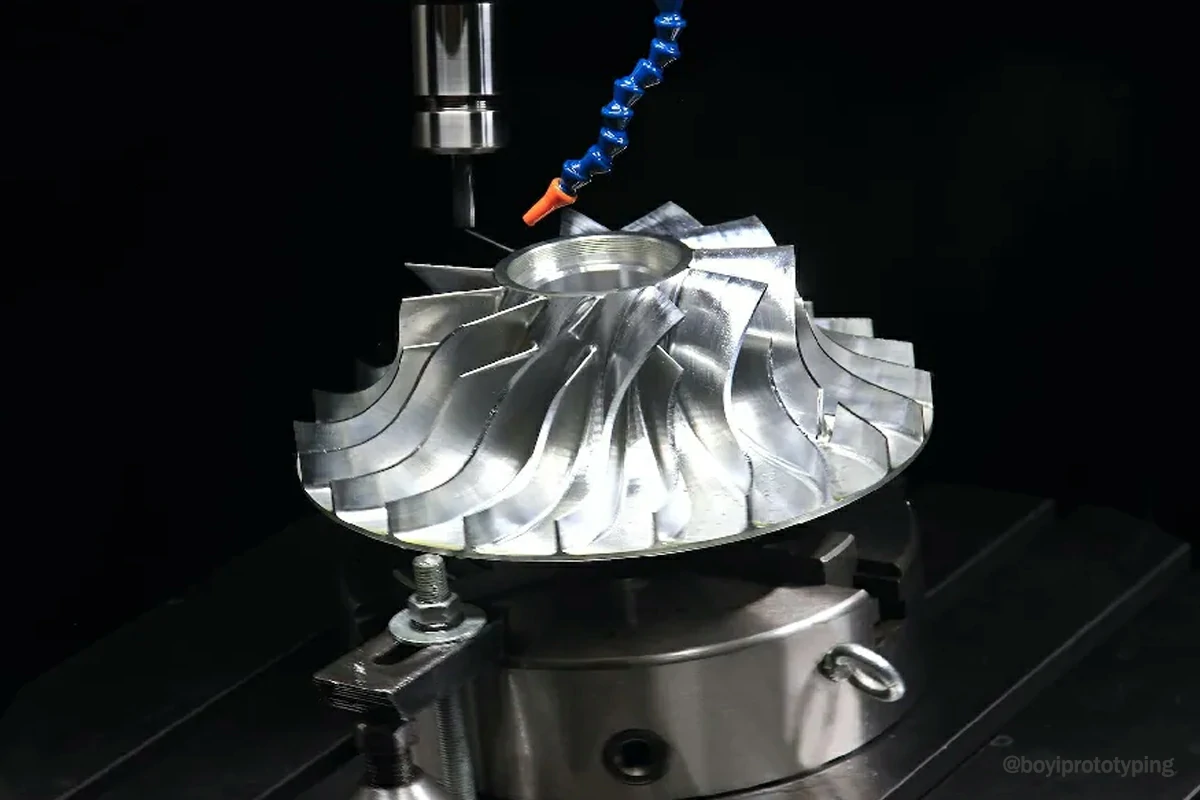

2. CNC megmunkálás: Addressing Complex Geometries in Aerospace Parts

The intricate designs of aerospace components, including undercuts and thin walls, pose significant machining challenges. These complexities necessitate advanced machining strategies to maintain structural integrity and functionality.

Megoldás: Utilizing multi-axis CNC machines and sophisticated CAD/CAM software enables the accurate production of complex geometries.

3. CNC megmunkálás: Managing Difficult-to-Machine Materials

Aerospace components often utilize materials like titanium and Inconel, known for their strength and resistance to extreme conditions but challenging to machine.

Megoldás: Employing specialized tooling, optimized cutting parameters, and appropriate cooling techniques facilitates efficient machining of these materials.

4. CNC megmunkálás: Ensuring Surface Integrity and Finish

Surface finish is critical in aerospace components to reduce friction and prevent fatigue. Achieving the desired finish requires precise control over machining processes.

Megoldás: Implementing fine-tuned machining parameters and post-processing techniques like polishing and anodizing ensures optimal surface quality.

5. CNC megmunkálás: Maintaining Consistency in Low-Volume Production

Aerospace manufacturing often involves low-volume production runs, where consistency across parts is crucial.

Megoldás: Standardizing machining processes and thorough documentation ensure uniformity in every component produced.

6. CNC megmunkálás: Adhering to Stringent Quality Standards

Compliance with aerospace quality standards like AS9100 is essential. This involves comprehensive quality management systems and continuous improvement practices.

Megoldás: Implementing robust quality assurance protocols and regular audits ensures adherence to industry standards.

7. CNC megmunkálás: Optimizing Tool Life and Performance

Machining aerospace materials can lead to rapid tool wear, affecting productivity and part quality.

Megoldás: Using high-quality tooling materials and monitoring tool conditions prolong tool life and maintain machining efficiency.

8. CNC megmunkálás: Integrating Advanced Technologies

Incorporating technologies like automation and real-time monitoring enhances machining precision and efficiency.

Megoldás: Adopting Industry 4.0 practices, including IoT-enabled machines and data analytics, optimizes CNC machining operations.

9. CNC megmunkálás: Managing Supply Chain and Lead Times

Timely delivery of aerospace components is critical. Delays can disrupt assembly lines and project timelines.

Megoldás: Establishing reliable supply chains and implementing just-in-time manufacturing practices ensure timely component delivery.

10. CNC megmunkálás: Collaborating with Experienced CNC Machining Service Providers

Partnering with seasoned CNC machining service providers like CNCRUSH ensures access to expertise, advanced equipment, and quality assurance practices essential for aerospace component manufacturing.

Megoldás: A CNCRUSH 12 éves tapasztalatának kiaknázása a CNC marás és CNC esztergálás területén garantálja a repülőgépipar igényeinek megfelelő, magas színvonalú alkatrészeket.

Table 1: Common Aerospace Materials and Machining Considerations

| Anyag | Tulajdonságok | Machining Considerations |

|---|---|---|

| Titán | High strength-to-weight ratio, corrosion-resistant | Requires sharp tools, low cutting speeds |

| Inconel | Heat-resistant, maintains strength at high temperatures | Needs specialized tooling, slow feed rates |

| Alumíniumötvözetek | Könnyű, jó megmunkálhatóság | Suitable for high-speed machining |

| Kompozitok | Nagy szilárdságú, könnyű | Requires specialized cutting techniques |

Table 2: CNC Machining Techniques for Aerospace Components

| Technika | Leírás | Alkalmazás |

|---|---|---|

| 5-tengelyes megmunkálás | Allows movement along five axes for complex geometries | Turbine blades, structural components |

| Swiss Turning | Precision machining for small, intricate parts | Rögzítők, csatlakozók |

| Electrical Discharge Machining (EDM) | Uses electrical discharges to shape hard materials | Tooling, dies |

| Laser Cutting | High-precision cutting using laser beams | Thin sheet components |

Gyakran Ismételt Kérdések (GYIK)

Q1: Why is CNC machining preferred in aerospace manufacturing?

A1: CNC precision machining offers high precision, repeatability, and the ability to work with a variety of materials, making it ideal for aerospace components that require strict tolerances and reliability.

Q2: What are the challenges of machining aerospace-grade materials?

A2: Aerospace materials like titanium and Inconel are tough and heat-resistant, making them difficult to machine. They require specialized tooling and machining strategies to ensure quality and efficiency.

Q3: How does CNCRUSH ensure the quality of aerospace components?

A3: CNCRUSH employs advanced CNC machines, experienced technicians, and rigorous quality control measures to produce high-precision CNC Milled parts and CNC Turned parts that meet aerospace industry standards.

Q4: Can CNCRUSH handle low-volume aerospace component production?

A4: Yes, CNCRUSH is equipped to manage both low and high-volume production runs, ensuring consistent quality and timely delivery for aerospace components.

Q5: What industries does CNCRUSH serve besides aerospace?

A5: In addition to aerospace, CNCRUSH provides CNC precision machining services for the automotive, machine building, and automation industries, offering customized solutions to meet diverse manufacturing needs.

For reliable and high-quality CNC machining services tailored to the aerospace industry, trust CNCRUSH. With over 12 years of experience in producing precision CNC Milled parts and CNC Turned parts, CNCRUSH is your go-to partner for all your aerospace component manufacturing needs.