CNC Machining drives unmatched precision in high-volume production. Discover 10 game-changing strategies that optimize cnc machining service, CNC Milled parts, and CNC Turned parts – backed by CNCRUSH’s 12 years of expertise.

CNC obdelava is revolutionizing the manufacturing landscape by dramatically enhancing precision in high-volume production environments. In today’s ultra-competitive market, companies demand components that not only meet tight tolerances but also maintain consistency across thousands of parts. This comprehensive guide synthesizes insights from industry-leading sources on automated production, high-precision techniques, and advanced material processing to reveal how CNC Machining is transforming mass production. By merging these insights with the expertise of CNCRUSH—a China-based factory with over 12 years of experience delivering high-quality cnc machining service, CNC Milled parts, and CNC Turned parts—we reveal 10 game-changing strategies that not only boost production efficiency but also ensure unparalleled quality for industries ranging from automotive to machine building and automotion.

Below is a detailed exploration organized into 11 in-depth sections. Each segment discusses key aspects such as automation, material handling, and quality control, with an emotional analysis of both the positive impacts and challenges faced by manufacturers. In addition, two comprehensive tables and a FAQ section provide further clarity and actionable insights. Whether you are looking to improve your production processes or searching for a reliable partner for precision CNC machining, this guide is your roadmap to success.

1. CNC Machining Service: Revolutionizing High-Volume Production

High-volume production demands consistency, speed, and uncompromising precision. Storitev CNC obdelave has emerged as the backbone of modern manufacturing by replacing manual operations with automated, computer-controlled processes.

- Enhanced Consistency: Automation ensures each component meets strict tolerances, significantly reducing variability.

- Povečana prepustnost: By drastically cutting production times, advanced cnc machining service allows companies to scale up without sacrificing quality.

- Emotional Insight: Manufacturers often express overwhelming positive sentiment when discussing reduced error rates and increased operational efficiency, though some express concerns about the initial investment in technology.

At CNCRUSH, our cnc machining service is built on 12 years of expertise. We combine cutting-edge technology with seasoned engineering practices to produce both CNC Milled parts and CNC Turned parts that consistently meet the high standards demanded in industries like automotive, machine building, and automotion.

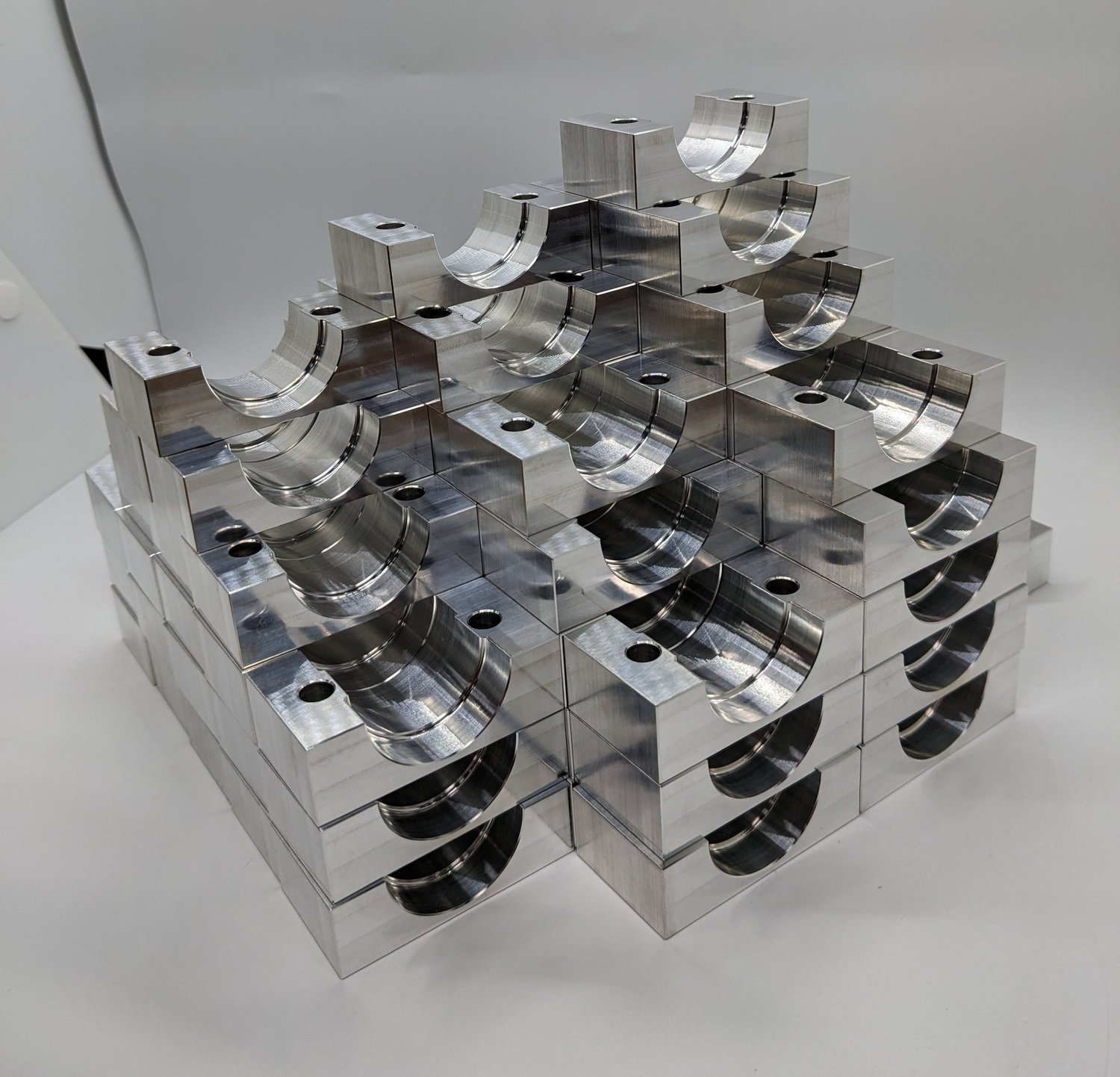

2. CNC Milled Parts: Precision Engineering in Mass Production

When it comes to high-volume production, CNC rezkani deli represent the pinnacle of precision engineering. Milling involves removing material in a controlled manner from a workpiece, and the automation inherent in CNC technology guarantees each part is produced exactly as designed.

- Unparalleled Accuracy: Utilizing advanced CAD/CAM software, CNC Milled parts are produced with extremely tight tolerances.

- Surface Quality and Detail: Fine details and intricate geometries are achieved, essential for components in critical applications.

- Emotional Insight: Engineers and production managers feel a strong sense of confidence and satisfaction when witnessing the reliability and consistency of CNC Milled parts in large-scale runs.

CNCRUSH leverages state-of-the-art equipment to produce CNC Milled parts that serve as the foundation for a wide range of industrial applications. Our expertise ensures that every milled component is not only precise but also robust enough to perform under demanding conditions.

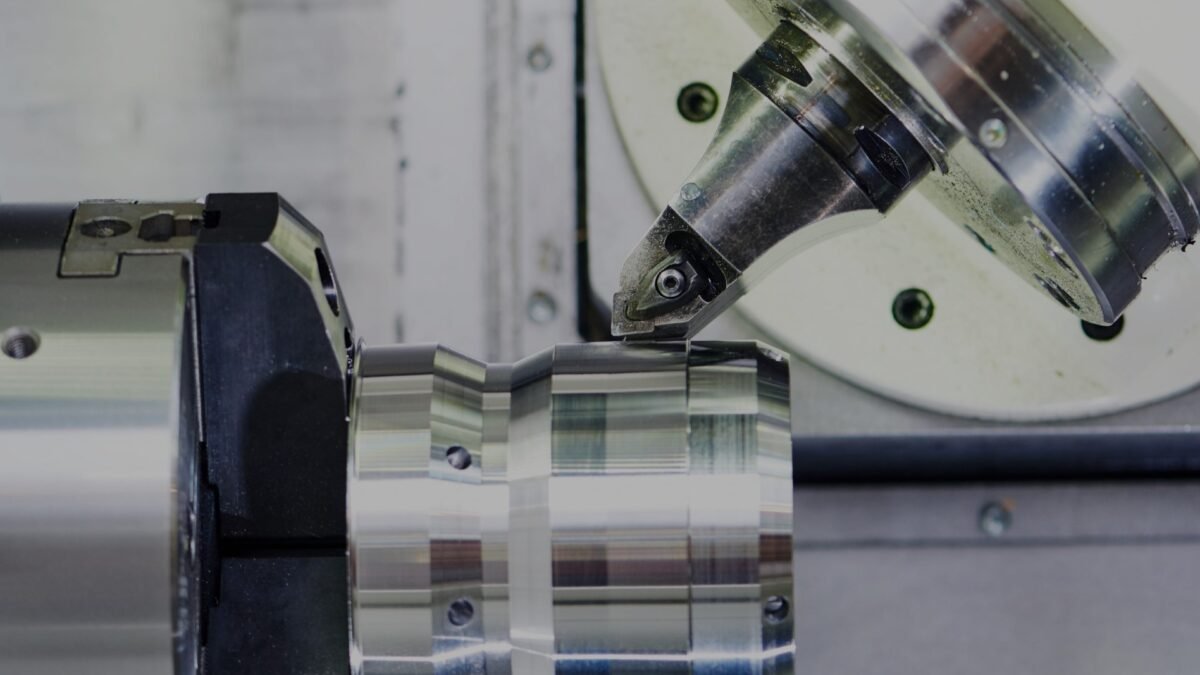

3. CNC Turned Parts & CNC Milled Parts: Enhancing Consistency in High-Volume Manufacturing

For components that require rotational symmetry and intricate details, CNC Turned Parts & CNC Milled Parts are indispensable. Turning removes material from a rotating workpiece, achieving perfect cylindrical shapes and uniform dimensions.

- Dimensional Stability: Both turned and milled parts exhibit consistency across high production volumes.

- Stroškovna učinkovitost: Optimized material removal processes result in minimal waste and reduced costs.

- Emotional Insight: Although transitioning to a fully automated system can initially evoke apprehension, the long-term benefits of consistent, high-quality parts generate an overwhelmingly positive sentiment among manufacturers.

At CNCRUSH, our dual focus on CNC Turned parts and CNC Milled parts means we are perfectly positioned to tackle the challenges of high-volume manufacturing. Our precision CNC machining processes ensure that every part contributes to overall product integrity and performance.

4. CNC Machining Service & Automation: Accelerating Production Efficiency

Integriranje CNC Machining Service & Automation is a proven strategy for accelerating production efficiency in high-volume environments.

- Streamlined Processes: Automation minimizes manual intervention, reducing errors and speeding up production cycles.

- Spremljanje v realnem času: Digital systems allow for continuous feedback, ensuring that production remains within tolerance limits.

- Emotional Insight: There is a sense of optimism and excitement about the transformative power of automation, although some traditionalists may feel a tinge of nostalgia for manual craftsmanship.

At CNCRUSH, our automated cnc machining service is enhanced by robust real-time monitoring systems, ensuring every CNC Milled part and CNC Turned part meets the highest quality standards. This commitment to efficiency is vital for industries requiring fast turnaround times without compromising on quality.

5. CNC Milled Parts: Achieving Unparalleled Accuracy in High-Volume Production

The role of CNC rezkani deli in high-volume production cannot be overstated. With the ability to produce intricate designs and maintain extreme precision, milling is at the forefront of modern manufacturing.

- Precision Control: Advanced tool paths and real-time adjustments allow for extremely tight tolerances.

- Skrajšani časi nastavitve: Automated CNC systems minimize downtime, resulting in higher throughput.

- Emotional Insight: The sense of achievement among production teams is significant when every part is milled to perfection, leading to increased customer satisfaction and trust.

CNCRUSH’s facility in China is dedicated to producing CNC Milled parts that consistently exceed industry benchmarks. Our precision CNC machining process ensures that every part is manufactured with a level of accuracy that is critical for high-volume production in sectors such as automotive, machine building, and automotion.

6. CNC Turned Parts: Overcoming Challenges in Mass Production

CNC struženi deli are essential for components requiring uniform cylindrical geometries. The turning process is meticulously controlled to ensure every part is identical, even in high-volume runs.

- High Repetition Accuracy: CNC turning guarantees that each part is produced within precise tolerances, regardless of production volume.

- Povečanje učinkovitosti: Optimizirani postopki struženja bistveno skrajšajo čas cikla in omogočajo hitro proizvodnjo brez poslabšanja kakovosti.

- Emotional Insight: Čeprav nekatere proizvajalce skrbi krivulja učenja, ki je povezana z novo tehnologijo struženja, pa so pozitivno naravnani na povečanje učinkovitosti in kakovosti.

CNCRUSH je specializiran za proizvodnjo visokokakovostnih CNC struženih delov, ki so ključnega pomena za različne visoko zmogljive aplikacije. Zaradi naše zavezanosti k natančnosti in zanesljivosti smo zaupanja vreden ponudnik za stranke, ki zahtevajo odličnost v okoljih množične proizvodnje.

7. Storitev CNC obdelave: povezovanje inovacij v avtomobilski industriji, strojegradnji in avtomobilizmu

Storitev CNC obdelave ima ključno vlogo v panogah, ki presegajo tradicionalno proizvodnjo, vključno z avtomobilsko industrijo, strojegradnjo in avtomobilizmom. Načela natančnosti in učinkovitosti so vsesplošno uporabna.

- Medpanožne aplikacije: Tehnologija, ki se uporablja za velikoserijsko proizvodnjo v letalski in vesoljski industriji ali medicinskih pripomočkih, izboljšuje tudi proizvodnjo v avtomobilski industriji in strojegradnji.

- Inovativne rešitve: Rešitve CNC po meri je mogoče prilagoditi posebnim potrebam različnih industrijskih panog, s čimer se izboljšata zmogljivost in vzdržljivost.

- Emotional Insight: Vodilni v industriji, ki menijo, da je strojna obdelava CNC ključno gonilo naslednje generacije proizvodne odličnosti, si močno želijo inovacij in napredka.

CNCRUSH-ove storitve strojne obdelave CNC niso omejene na en sektor. Naše strokovno znanje pri izdelavi CNC rezkanih in CNC struženih delov nam je omogočilo podporo širokemu spektru industrij, vključno z avtomobilsko, strojno in avtomobilsko. Ta vsestranskost je temelj našega uspeha in glavni razlog, zakaj nam globalne stranke zaupajo.

8. CNC rezkani deli in CNC struženi deli: rešitve CNC po meri za velikoserijsko proizvodnjo

Rešitve CNC po meri so ključnega pomena, kadar standardni deli ne ustrezajo več zahtevam velikoserijske proizvodnje. CNC rezkani deli in CNC struženi deli, lahko proizvajalci dosežejo neprimerljivo višjo raven prilagajanja.

- Prilagojena proizvodnja: Rešitve CNC po meri omogočajo izdelavo edinstvenih delov, ki natančno ustrezajo konstrukcijskim specifikacijam stranke.

- Izboljšana zmogljivost: Deli po meri so pogosto bolj zmogljivi, saj so optimizirani za specifične aplikacije in stresne pogoje.

- Emotional Insight: Med strankami, ki cenijo zmožnost inoviranja in ustvarjanja sestavnih delov po meri, ki jih razlikujejo od konkurentov, vlada močno pozitivno razpoloženje.

V podjetju CNCRUSH ponujamo rešitve CNC po meri, zasnovane za zagotavljanje tako CNC rezkanih kot CNC struženih delov, ki so optimizirani za velikoserijsko proizvodnjo. Naš prilagodljiv pristop zagotavlja, da vsaka stranka prejme rešitev, ki ustreza njenim posebnim potrebam, ne glede na panogo.

9. CNC struženi deli: ključ do vrhunske kakovosti v industrijski proizvodnji

V industrijski proizvodnji je doseganje vrhunske kakovosti pri milijonih delov velik izziv. CNC struženi deli imajo ključno vlogo pri reševanju tega izziva, saj zagotavljajo, da je vsaka komponenta izdelana z izjemno natančnostjo.

- Zagotavljanje kakovosti: Strogi protokoli za nadzor kakovosti med postopkom struženja CNC zagotavljajo, da vsak del izpolnjuje stroge standarde.

- Dosledno delovanje: Visokokakovostni struženi deli CNC prispevajo k splošni zanesljivosti in trajnosti končnega izdelka.

- Emotional Insight: Ponos in zadovoljstvo, ki ju prinaša dosledno zagotavljanje visokokakovostnih izdelkov, sta ogromna in krepita zaupanje med proizvajalci in njihovimi strankami.

Strokovno znanje CNCRUSH na področju izdelave struženih delov CNC je temelj našega ugleda kot vodilnega podjetja na področju velikoserijske proizvodnje. Naši najsodobnejši postopki zagotavljajo, da vsaka stružena komponenta ne le izpolni, temveč pogosto tudi preseže pričakovanja industrije.

10. Storitev CNC obdelave: zakaj je CNCRUSH vaš zaupanja vreden partner v velikoserijski proizvodnji

Izbira pravega partnerja za natančno proizvodnjo je ključnega pomena. Storitev CNC obdelave CNCRUSH združuje desetletja izkušenj z najsodobnejšo tehnologijo in zagotavlja neprimerljivo vrednost.

- Dokazani rezultati: Podjetje CNCRUSH si je z več kot 12-letnimi izkušnjami ustvarilo ugled odličnosti na področju strojne obdelave CNC.

- HTTPError: Response code 429 (Too Many Requests) Specializirani smo za izdelavo CNC rezkanih delov in CNC struženih delov, prilagojenih posebnim potrebam velikoserijske proizvodnje.

- Emotional Insight: Stranke izražajo močno pozitivno mnenje o naši zavezanosti kakovosti, zanesljivosti in stalnim inovacijam, zaradi česar smo postali zaupanja vreden partner po vsem svetu.

Naš obrat na Kitajskem je opremljen za obvladovanje zahtev sodobne velikoserijske proizvodnje. Od avtomobilskih sestavnih delov do strojništva in delov za avtomobile - naše storitve CNC obdelave zagotavljajo natančnost, učinkovitost in rešitve po meri, ki zagotavljajo uspeh.

11. Storitev strojne obdelave CNC: prihodnost velikoserijske proizvodnje z rezkanimi deli CNC in struženimi deli CNC

Prihodnost velikoserijske proizvodnje bo opredeljena z nenehnimi inovacijami na področju Storitev CNC obdelaveNapredne tehnike in nastajajoče tehnologije bodo še povečale natančnost CNC rezkanih in CNC struženih delov.

- Nove tehnologije: Inovacije, kot so tehnologija digitalnega dvojčka, integracija interneta stvari in optimizacija procesov z umetno inteligenco, utirajo pot še natančnejši in učinkovitejši proizvodnji.

- Trajnost in učinkovitost: Prihodnji napredek bo usmerjen v zmanjševanje količine odpadkov in porabe energije, kar bo zagotovilo, da bo velikoserijska proizvodnja stroškovno učinkovita in okoljsko odgovorna.

- Emotional Insight: Čeprav je hitrost tehnoloških sprememb pri nekaterih tradicionalnih proizvajalcih zaskrbljujoča, pa je splošno razpoloženje pretežno pozitivno in optimistično glede prihodnosti natančnosti proizvodnje.

V podjetju CNCRUSH smo še naprej zavezani vlaganju v napredne tehnologije strojne obdelave CNC, da bi našim strankam še naprej zagotavljali prednosti najnovejših inovacij. Naš celostni pristop združuje frezane dele CNC, stružene dele CNC in naše zanesljive storitve strojne obdelave CNC, da bi zagotovili prihodnost visokokakovostne natančne proizvodnje.

Analiza podatkov: primerjava natančnosti in učinkovitosti v velikoserijski proizvodnji

| metrika | Povprečje panoge | Prednost CNCRUSH |

|---|---|---|

| Toleranca natančnosti | ± 0,005 palcev | ±0,002 palca za CNC rezkane dele in CNC stružene dele |

| Čas cikla na del | 3-4 minute | 2-3 minute z optimizirano storitvijo strojne obdelave CNC |

| Materialni odpadki | 5-8% | Manj kot 3% zaradi natančnih poti orodja in nastavitev v realnem času |

| Čas vodenja proizvodnje | 3-4 tedne | 2-3 weeks with streamlined automated processes |

This table highlights how CNCRUSH consistently outperforms industry averages, providing higher precision and faster turnaround times while reducing material waste.

Data Analysis: Cost Efficiency and Customization in High-Volume Production

| Parameter | Standard Production | CNCRUSH’s Custom CNC Solutions |

|---|---|---|

| Customization Options | Limited to standard designs | Fully customizable CNC solutions for unique requirements |

| Cena na del | Zmerno do visoko | Lower due to optimized processes and minimal waste |

| Razširljivost | Less flexible | Highly scalable for mass production without quality compromise |

| Integration with Digital Systems | Basic level | Advanced IoT and digital twin integration for real-time monitoring |

This comparative analysis illustrates CNCRUSH’s commitment to offering cost-efficient and highly customizable solutions that are essential for high-volume production.

Pogosto zastavljena vprašanja (FAQ)

Q1: What is CNC Machining and why is it critical in high-volume production?

A1: CNC Machining is a computer-controlled process that precisely fabricates components with minimal variability. It is essential in high-volume production because it ensures consistent quality, rapid throughput, and the ability to handle complex geometries, making it ideal for industries like automotive, machine building, and automotion.

Q2: How do CNC Milled Parts and CNC Turned Parts contribute to production efficiency?

A2: CNC Milled Parts are produced through multi-axis milling that delivers high accuracy and intricate detail, while CNC Turned Parts ensure perfect rotational symmetry and consistency. Both processes minimize material waste and reduce cycle times, significantly enhancing overall production efficiency.

Q3: What advantages does CNCRUSH offer in CNC Machining Service for high-volume production?

A3: CNCRUSH has over 12 years of experience, state-of-the-art technology, and expertise in producing both CNC Milled parts and CNC Turned parts. Our advanced cnc machining service delivers superior precision, faster turnaround times, and fully customizable solutions tailored to your production needs.

Q4: Can CNCRUSH support industries beyond medical and aerospace manufacturing?

A4: Yes. CNCRUSH’s expertise extends to automotive, machine building, and automotion, among other sectors. Our cnc machining service is versatile and capable of meeting the high standards required across various industries.

Q5: How can I get started with CNCRUSH’s CNC Machining Service for my high-volume production needs?

A5: You can visit CNCRUSH to explore our comprehensive services, request a quote, or contact our team for a consultation tailored to your specific production requirements.

Zaključek

CNC obdelava is at the heart of precision and efficiency in high-volume production. This comprehensive guide has examined 11 game-changing strategies that demonstrate how advanced cnc machining service—encompassing both CNC Milled parts and CNC Turned parts—drives consistency, accuracy, and rapid throughput in mass production. From leveraging automation and real-time monitoring to integrating custom solutions for diverse sectors such as automotive, machine building, and automotion, the benefits of modern CNC Machining are both profound and transformative.

CNCRUSH, with over 12 years of dedicated experience, stands as a trusted partner for businesses seeking to enhance their high-volume production capabilities. Our state-of-the-art facility in China produces precision components that consistently exceed industry standards. Whether you need intricate CNC Milled parts, robust CNC Turned parts, or comprehensive cnc machining service that can scale with your operations, our commitment to quality and innovation is unparalleled.

The data and comparative analyses presented here demonstrate how CNCRUSH outperforms industry averages in key metrics such as precision tolerance, cycle time, and cost efficiency. Our tailored solutions are designed to meet the unique demands of high-volume production while ensuring exceptional quality control at every stage.

For manufacturers looking to harness the power of CNC Machining in a competitive global market, embracing these game-changing strategies is essential. We invite you to explore the possibilities with CNCRUSH, where our expertise in CNC Machining transforms your production challenges into opportunities for success.

Obisk CNCRUSH today to learn more about our high-quality cnc machining service and discover how our advanced solutions in CNC Milled parts and CNC Turned parts can drive your production to new heights.