CNC Machining drives unmatched precision in high-volume production. Discover 10 game-changing strategies that optimize cnc machining service, CNC Milled parts, and CNC Turned parts – backed by CNCRUSH’s 12 years of expertise.

Prelucrare CNC is revolutionizing the manufacturing landscape by dramatically enhancing precision in high-volume production environments. In today’s ultra-competitive market, companies demand components that not only meet tight tolerances but also maintain consistency across thousands of parts. This comprehensive guide synthesizes insights from industry-leading sources on automated production, high-precision techniques, and advanced material processing to reveal how CNC Machining is transforming mass production. By merging these insights with the expertise of CNCRUSH—a China-based factory with over 12 years of experience delivering high-quality cnc machining service, CNC Milled parts, and CNC Turned parts—we reveal 10 game-changing strategies that not only boost production efficiency but also ensure unparalleled quality for industries ranging from automotive to machine building and automotion.

Below is a detailed exploration organized into 11 in-depth sections. Each segment discusses key aspects such as automation, material handling, and quality control, with an emotional analysis of both the positive impacts and challenges faced by manufacturers. In addition, two comprehensive tables and a FAQ section provide further clarity and actionable insights. Whether you are looking to improve your production processes or searching for a reliable partner for precision CNC machining, this guide is your roadmap to success.

1. CNC Machining Service: Revolutionizing High-Volume Production

High-volume production demands consistency, speed, and uncompromising precision. Serviciu de prelucrare CNC has emerged as the backbone of modern manufacturing by replacing manual operations with automated, computer-controlled processes.

- Enhanced Consistency: Automation ensures each component meets strict tolerances, significantly reducing variability.

- Randament crescut: By drastically cutting production times, advanced cnc machining service allows companies to scale up without sacrificing quality.

- Emotional Insight: Manufacturers often express overwhelming positive sentiment when discussing reduced error rates and increased operational efficiency, though some express concerns about the initial investment in technology.

At CNCRUSH, our cnc machining service is built on 12 years of expertise. We combine cutting-edge technology with seasoned engineering practices to produce both CNC Milled parts and CNC Turned parts that consistently meet the high standards demanded in industries like automotive, machine building, and automotion.

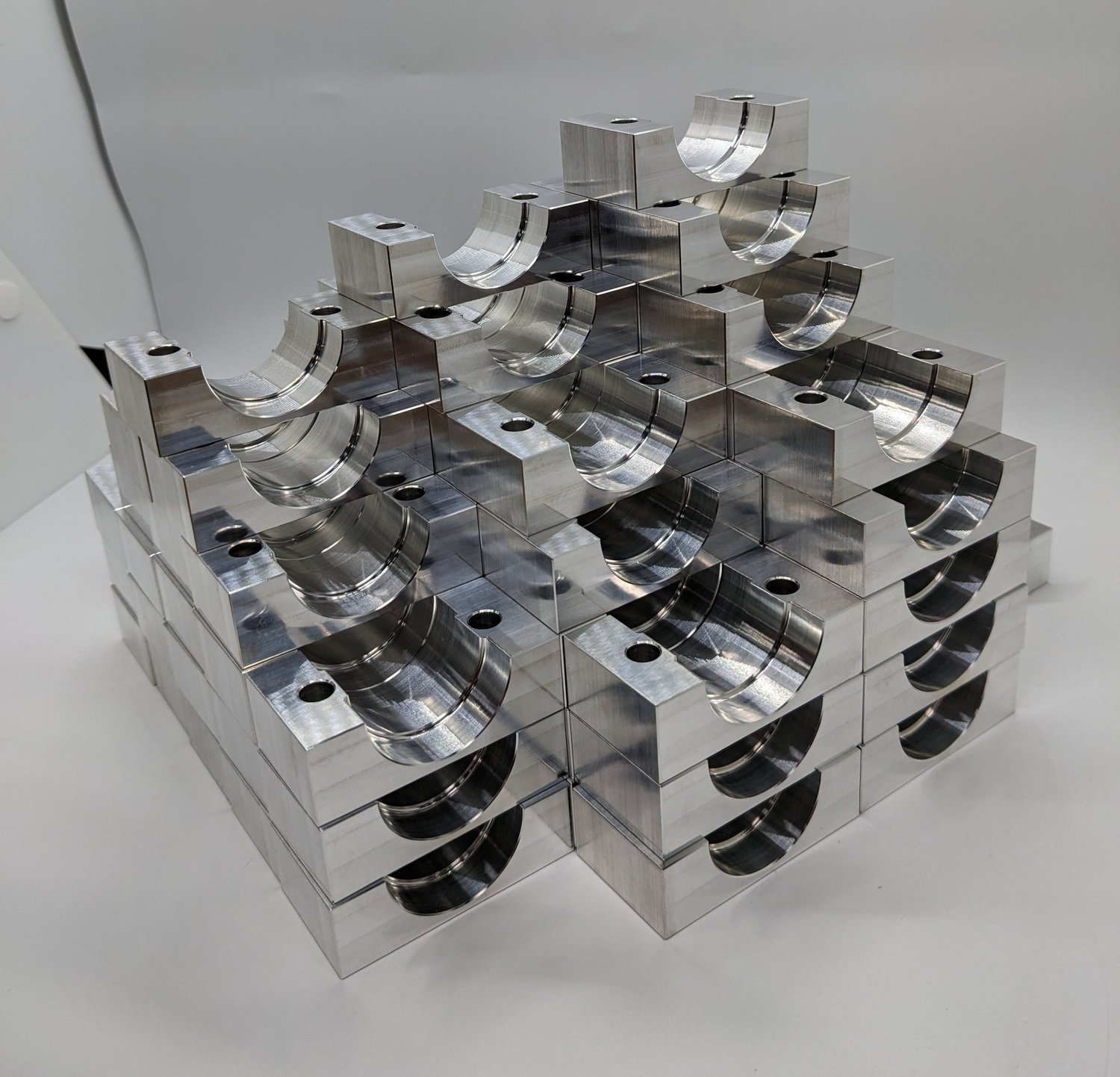

2. CNC Milled Parts: Precision Engineering in Mass Production

When it comes to high-volume production, Piese frezate CNC represent the pinnacle of precision engineering. Milling involves removing material in a controlled manner from a workpiece, and the automation inherent in CNC technology guarantees each part is produced exactly as designed.

- Unparalleled Accuracy: Utilizing advanced CAD/CAM software, CNC Milled parts are produced with extremely tight tolerances.

- Surface Quality and Detail: Fine details and intricate geometries are achieved, essential for components in critical applications.

- Emotional Insight: Engineers and production managers feel a strong sense of confidence and satisfaction when witnessing the reliability and consistency of CNC Milled parts in large-scale runs.

CNCRUSH leverages state-of-the-art equipment to produce CNC Milled parts that serve as the foundation for a wide range of industrial applications. Our expertise ensures that every milled component is not only precise but also robust enough to perform under demanding conditions.

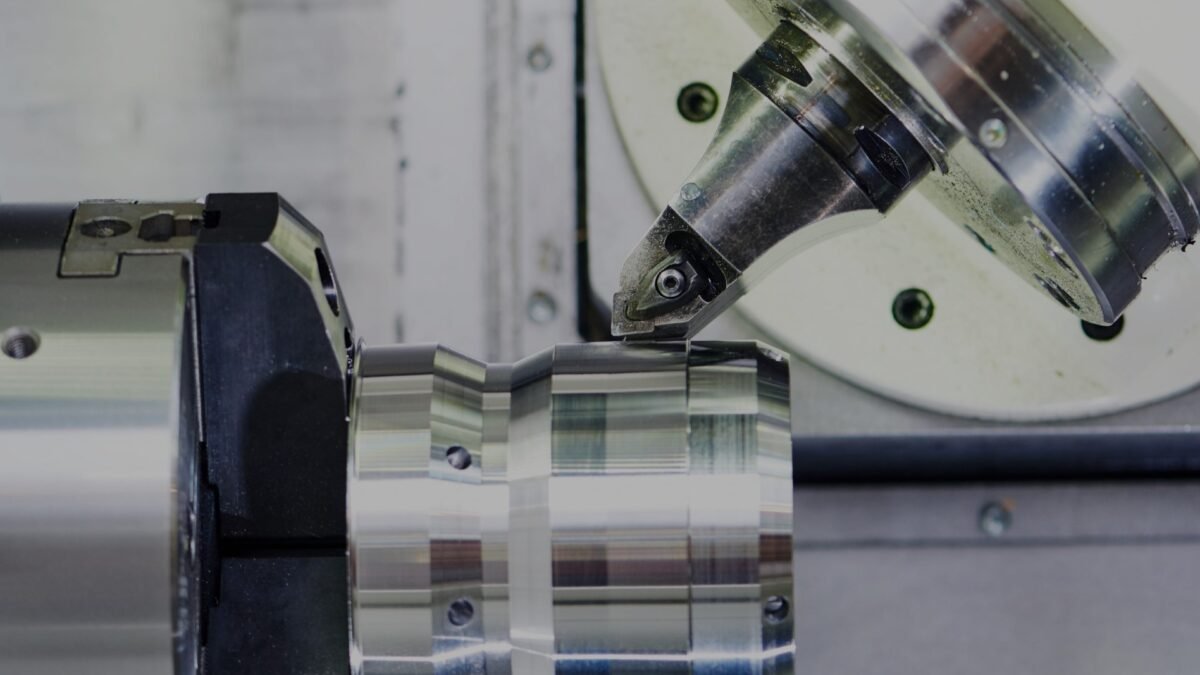

3. CNC Turned Parts & CNC Milled Parts: Enhancing Consistency in High-Volume Manufacturing

For components that require rotational symmetry and intricate details, CNC Turned Parts & CNC Milled Parts are indispensable. Turning removes material from a rotating workpiece, achieving perfect cylindrical shapes and uniform dimensions.

- Stabilitatea dimensională: Both turned and milled parts exhibit consistency across high production volumes.

- Cost-eficacitate: Optimized material removal processes result in minimal waste and reduced costs.

- Emotional Insight: Although transitioning to a fully automated system can initially evoke apprehension, the long-term benefits of consistent, high-quality parts generate an overwhelmingly positive sentiment among manufacturers.

At CNCRUSH, our dual focus on CNC Turned parts and CNC Milled parts means we are perfectly positioned to tackle the challenges of high-volume manufacturing. Our precision CNC machining processes ensure that every part contributes to overall product integrity and performance.

4. CNC Machining Service & Automation: Accelerating Production Efficiency

Integrarea CNC Machining Service & Automation is a proven strategy for accelerating production efficiency in high-volume environments.

- Streamlined Processes: Automation minimizes manual intervention, reducing errors and speeding up production cycles.

- Monitorizare în timp real: Digital systems allow for continuous feedback, ensuring that production remains within tolerance limits.

- Emotional Insight: There is a sense of optimism and excitement about the transformative power of automation, although some traditionalists may feel a tinge of nostalgia for manual craftsmanship.

At CNCRUSH, our automated cnc machining service is enhanced by robust real-time monitoring systems, ensuring every CNC Milled part and CNC Turned part meets the highest quality standards. This commitment to efficiency is vital for industries requiring fast turnaround times without compromising on quality.

5. CNC Milled Parts: Achieving Unparalleled Accuracy in High-Volume Production

The role of Piese frezate CNC in high-volume production cannot be overstated. With the ability to produce intricate designs and maintain extreme precision, milling is at the forefront of modern manufacturing.

- Precision Control: Advanced tool paths and real-time adjustments allow for extremely tight tolerances.

- Timpuri de configurare reduse: Automated CNC systems minimize downtime, resulting in higher throughput.

- Emotional Insight: The sense of achievement among production teams is significant when every part is milled to perfection, leading to increased customer satisfaction and trust.

CNCRUSH’s facility in China is dedicated to producing CNC Milled parts that consistently exceed industry benchmarks. Our precision CNC machining process ensures that every part is manufactured with a level of accuracy that is critical for high-volume production in sectors such as automotive, machine building, and automotion.

6. CNC Turned Parts: Overcoming Challenges in Mass Production

Piese turnate CNC are essential for components requiring uniform cylindrical geometries. The turning process is meticulously controlled to ensure every part is identical, even in high-volume runs.

- High Repetition Accuracy: CNC turning guarantees that each part is produced within precise tolerances, regardless of production volume.

- Câștiguri de eficiență: Optimized turning processes significantly cut down cycle times, enabling rapid production without compromising quality.

- Emotional Insight: While some manufacturers may worry about the learning curve associated with new turning technology, the resulting gains in efficiency and quality evoke a strong positive sentiment.

CNCRUSH specializes in producing high-quality CNC Turned parts that are crucial for various high-performance applications. Our commitment to precision and reliability makes us a trusted provider for customers who demand excellence in mass production environments.

7. CNC Machining Service: Integrating Innovation in Automotive, Machine Building and Automotion

Serviciu de prelucrare CNC plays a critical role in industries beyond traditional manufacturing, including automotive, machine building, and automotion. The principles of precision and efficiency are universally applicable.

- Cross-Industry Applications: The technology used for high-volume production in aerospace or medical devices also enhances production in automotive and machine building sectors.

- Innovative Solutions: Custom CNC solutions can be tailored to meet the specific needs of different industries, enhancing both performance and durability.

- Emotional Insight: There is a deep sense of innovation and progress among industry leaders who see CNC machining as a key driver in the next generation of manufacturing excellence.

CNCRUSH’s cnc machining service is not limited to one sector. Our expertise in producing both CNC Milled parts and CNC Turned parts has allowed us to support a wide array of industries, including automotive, machine building, and automotion. This versatility is a cornerstone of our success and a primary reason why global clients trust us.

8. CNC Milled Parts & CNC Turned Parts: Custom CNC Solutions for High-Volume Production

Custom CNC solutions are critical when standard parts no longer meet the demands of high-volume production. By combining the strengths of CNC Milled Parts & CNC Turned Parts, manufacturers can achieve unprecedented levels of customization.

- Tailored Production: Custom CNC solutions allow for the production of unique parts that precisely meet the design specifications of a client.

- Performanță îmbunătățită: Custom parts often lead to enhanced performance, as they are optimized for specific applications and stress conditions.

- Emotional Insight: There is a strong positive sentiment among customers who value the ability to innovate and create bespoke components that set them apart from competitors.

At CNCRUSH, we offer custom CNC solutions designed to deliver both CNC Milled parts and CNC Turned parts that are optimized for high-volume production. Our flexible approach ensures that every client receives a solution that meets their specific needs, regardless of the industry.

9. CNC Turned Parts: Key to Superior Quality in Industrial Manufacturing

In industrial manufacturing, achieving superior quality across millions of parts is a formidable challenge. Piese turnate CNC play a pivotal role in meeting this challenge by ensuring every component is produced with exacting precision.

- Asigurarea calității: Rigorous quality control protocols during the CNC turning process ensure that each part adheres to strict standards.

- Consistent Performance: High-quality CNC Turned parts contribute to the overall reliability and durability of the final product.

- Emotional Insight: The pride and satisfaction derived from delivering consistently high-quality products are immense, reinforcing trust between manufacturers and their clients.

CNCRUSH’s expertise in producing CNC Turned parts underpins our reputation as a leader in high-volume production. Our state-of-the-art processes ensure that every turned component not only meets but often exceeds industry expectations.

10. CNC Machining Service: Why CNCRUSH is Your Trusted Partner in High-Volume Production

Selecting the right partner for precision manufacturing is crucial. Serviciu de prelucrare CNC from CNCRUSH combines decades of experience with cutting-edge technology to provide unmatched value.

- Bilanț dovedit: With over 12 years of experience, CNCRUSH has built a reputation for excellence in CNC machining.

- HTTPError: Response code 429 (Too Many Requests) We specialize in producing both CNC Milled parts and CNC Turned parts, tailored to the specific needs of high-volume production.

- Emotional Insight: Clients express strong positive sentiment regarding our commitment to quality, reliability, and continuous innovation, which has made us a trusted partner globally.

Our facility in China is equipped to handle the demands of modern high-volume production. From automotive components to machine building and automotion parts, our cnc machining service delivers precision, efficiency, and custom solutions that drive success.

11. CNC Machining Service: The Future of High-Volume Production with CNC Milled Parts & CNC Turned Parts

Looking ahead, the future of high-volume production will be defined by continuous innovation in Serviciu de prelucrare CNC. Advanced techniques and emerging technologies are set to further enhance the precision of both CNC Milled parts and CNC Turned parts.

- Emerging Technologies: Innovations such as digital twin technology, IoT integration, and AI-driven process optimization are paving the way for even more precise and efficient production.

- Sustainability and Efficiency: Future advancements will focus on reducing waste and energy consumption, ensuring that high-volume production is both cost-effective and environmentally responsible.

- Emotional Insight: While the pace of technological change may generate apprehension among some traditional manufacturers, the overall sentiment is overwhelmingly positive, with optimism about the future of manufacturing precision.

At CNCRUSH, we remain committed to investing in advanced CNC machining technologies to ensure that our customers continue to benefit from the latest innovations. Our integrated approach combines CNC Milled parts, CNC Turned parts, and our robust cnc machining service to deliver the future of high-volume precision production.

Data Analysis: Benchmarking Precision and Efficiency in High-Volume Production

| Metric | Media industriei | Avantajul CNCRUSH |

|---|---|---|

| Toleranță de precizie | ± 0,005 inci | ±0.002 inches for both CNC Milled parts and CNC Turned parts |

| Timp de ciclu per parte | 3-4 minutes | 2-3 minutes through optimized cnc machining service |

| Deșeuri materiale | 5-8% | Less than 3% due to precise tool paths and real-time adjustments |

| Production Lead Time | 3-4 săptămâni | 2-3 weeks with streamlined automated processes |

This table highlights how CNCRUSH consistently outperforms industry averages, providing higher precision and faster turnaround times while reducing material waste.

Analiza datelor: Eficiența costurilor și personalizarea în producția de volum mare

| Parametru | Producție standard | Soluții CNC personalizate CNCRUSH |

|---|---|---|

| Opțiuni de personalizare | Limitat la modele standard | Soluții CNC complet personalizabile pentru cerințe unice |

| Cost pe parte | Moderat spre ridicat | Mai mici datorită proceselor optimizate și a deșeurilor minime |

| Scalabilitate | Mai puțin flexibil | Extrem de scalabil pentru producția de masă fără a compromite calitatea |

| Integrarea cu sistemele digitale | Nivel de bază | Integrare avansată IoT și digital twin pentru monitorizare în timp real |

Această analiză comparativă ilustrează angajamentul CNCRUSH de a oferi soluții eficiente din punct de vedere al costurilor și foarte personalizabile, care sunt esențiale pentru producția de volum mare.

Întrebări frecvente (FAQ)

Q1: Ce este prelucrarea CNC și de ce este esențială în producția de volum mare?

A1: Prelucrarea CNC este un proces controlat de computer care fabrică cu precizie componente cu o variabilitate minimă. Este esențială în producția de volum mare, deoarece asigură o calitate constantă, un randament rapid și capacitatea de a gestiona geometrii complexe, ceea ce o face ideală pentru industrii precum industria auto, construcția de mașini și automobile.

Q2: Cum contribuie piesele frezate CNC și piesele strunjite CNC la eficiența producției?

A2: Piesele frezate CNC sunt produse prin frezare pe mai multe axe care asigură o precizie ridicată și detalii complexe, în timp ce piesele strunjite CNC asigură o simetrie și o consistență rotațională perfectă. Ambele procese minimizează risipa de material și reduc timpii de ciclu, îmbunătățind semnificativ eficiența generală a producției.

Q3: Ce avantaje oferă CNCRUSH în serviciile de prelucrare CNC pentru producția de volum mare?

A3: CNCRUSH are peste 12 ani de experiență, tehnologie de ultimă oră și expertiză în producerea atât a pieselor frezate CNC, cât și a pieselor strunjite CNC. Serviciul nostru avansat de prelucrare cnc oferă precizie superioară, timpi de răspuns mai rapizi și soluții complet personalizabile adaptate nevoilor dvs. de producție.

Q4: Poate CNCRUSH să sprijine alte industrii în afară de industria medicală și aerospațială?

A4: Da. Expertiza CNCRUSH se extinde la industria auto, construcția de mașini și automobile, printre alte sectoare. Serviciul nostru de prelucrare cnc este versatil și capabil să îndeplinească standardele ridicate cerute în diverse industrii.

Q5: Cum pot începe să folosesc serviciul de prelucrare CNC al CNCRUSH pentru nevoile mele de producție de volum mare?

A5: Puteți vizita CNCRUSH pentru a explora serviciile noastre complete, pentru a solicita o ofertă sau pentru a contacta echipa noastră pentru o consultare adaptată cerințelor dvs. specifice de producție.

Concluzie

Prelucrare CNC Acest ghid cuprinzător a examinat 11 strategii de schimbare a jocului care demonstrează modul în care serviciile avansate de prelucrare cnc - care includ atât piese frezate CNC, cât și piese strunjite CNC - conduc la consecvență, precizie și randament rapid în producția de masă. De la valorificarea automatizării și monitorizării în timp real la integrarea soluțiilor personalizate pentru diverse sectoare, cum ar fi cel auto, construcția de mașini și automobile, beneficiile prelucrării CNC moderne sunt atât profunde, cât și transformatoare.

CNCRUSH, cu peste 12 ani de experiență dedicată, este un partener de încredere pentru întreprinderile care doresc să își îmbunătățească capacitățile de producție de volum mare. Instalația noastră de ultimă generație din China produce componente de precizie care depășesc în mod constant standardele industriei. Fie că aveți nevoie de piese complicate frezate CNC, de piese robuste strunjite CNC sau de servicii complete de prelucrare cnc care pot crește odată cu operațiunile dumneavoastră, angajamentul nostru față de calitate și inovare este de neegalat.

Datele și analizele comparative prezentate aici demonstrează modul în care CNCRUSH depășește mediile din industrie în ceea ce privește parametrii cheie, cum ar fi toleranța de precizie, timpul de ciclu și eficiența costurilor. Soluțiile noastre personalizate sunt concepute pentru a satisface cerințele unice ale producției de volum mare, asigurând în același timp un control excepțional al calității în fiecare etapă.

Pentru producătorii care doresc să valorifice puterea prelucrării CNC pe o piață globală competitivă, adoptarea acestor strategii de schimbare a jocului este esențială. Vă invităm să explorați posibilitățile cu CNCRUSH, unde expertiza noastră în prelucrarea CNC vă transformă provocările de producție în oportunități de succes.

Vizita CNCRUSH astăzi pentru a afla mai multe despre serviciile noastre de prelucrare cnc de înaltă calitate și pentru a descoperi cum soluțiile noastre avansate în domeniul pieselor frezate CNC și al pieselor strunjite CNC vă pot duce producția la noi înălțimi.