CNC Freze is the cornerstone of modern metalworking, enabling the production of high-precision components critical for industries such as aerospace, automotive, machine building, and automotion. In this comprehensive article, we summarize insights from leading sources on CNC manufacturing, precision CNC milling basics, and the multifaceted applications of CNC machining. By integrating these insights with the expertise of CNCRUSH—a trusted China-based CNC işleme hizmeti provider with 12+ years of experience specializing in CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar—we reveal 10 powerful secrets that drive exceptional precision and efficiency in metalworking.

This guide provides a deep dive into the fundamentals, benefits, and challenges of CNC Milling, presenting 10 in-depth discussions. Each section offers detailed analysis, comparative data through tables, and a FAQ section addressing common queries. Whether you are an engineer, production manager, or a decision-maker in high-precision metal fabrication, this article will equip you with the knowledge to optimize your manufacturing processes using advanced CNC Milling techniques.

1. CNC Milling: Understanding the Basics of High-Precision Metalworking

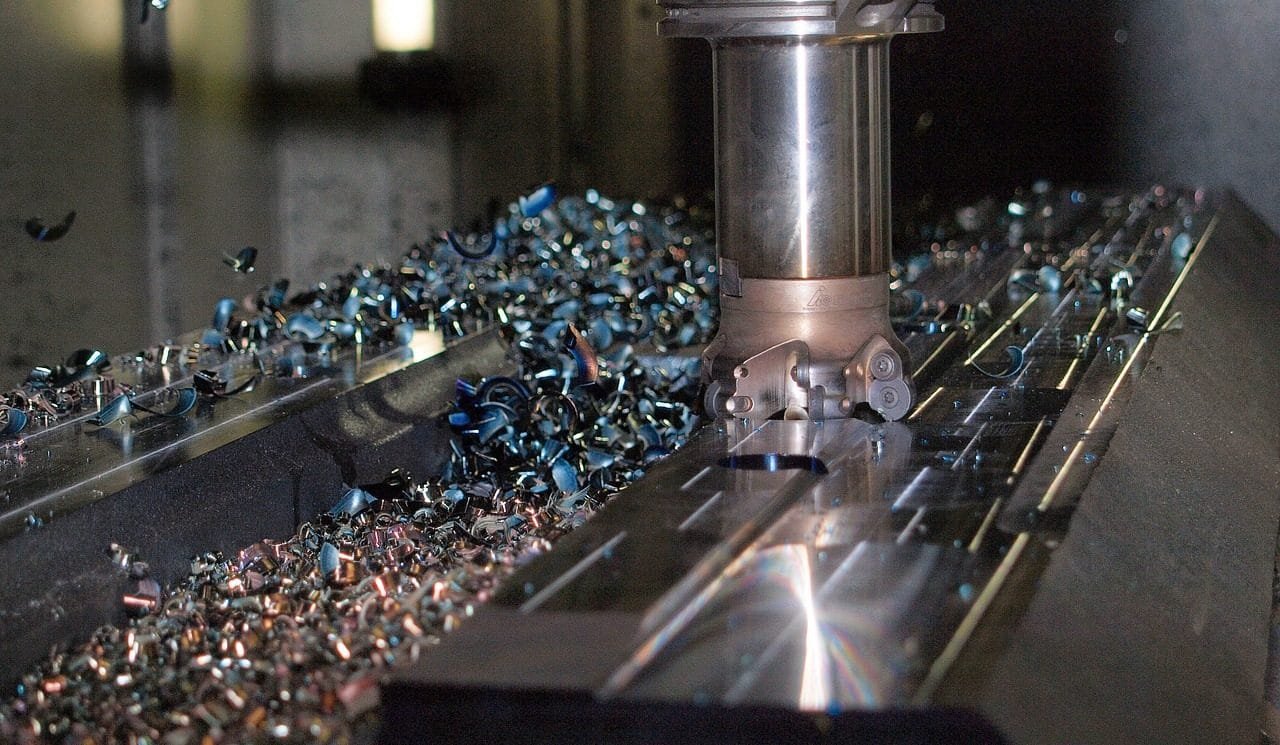

CNC Freze is a subtractive manufacturing process where material is removed from a workpiece using rotating cutting tools. This process is essential for producing complex, precise components with tight tolerances and excellent surface finishes. Its versatility makes it a preferred method for both prototyping and production across various industries.

Key Concepts:

- Subtractive Process: Material is removed from a solid block, resulting in high-precision parts.

- Automation and Consistency: CNC Milling machines offer repeatability that minimizes human error.

- Çok Yönlü Uygulamalar: Capable of machining a range of materials including aluminum, steel, brass, and plastics.

Understanding these basics sets the stage for exploring how CNC Milling transforms metalworking, making it indispensable for high-precision applications.

2. CNC Milling in Advanced Metalworking: The Impact on CNC Machining Service

High-precision metalworking demands robust and reliable processes. CNC Freze not only meets these demands but also revolutionizes production workflows. For companies looking for a professional CNC işleme hizmeti, leveraging CNC Milling means increased accuracy, reduced waste, and superior product consistency.

Benefits for CNC Machining Service Providers:

- Enhanced Precision: Achieve tighter tolerances essential for high-quality components.

- Artan Verimlilik: Reduced need for secondary finishing operations.

- Maliyet Verimliliği: Optimized processes lead to lower production costs in the long run.

By partnering with experienced providers like CNCRUSH, clients can access custom solutions that incorporate both CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar, ensuring that every component meets the highest standards required in industries such as automotive and machine building.

3. The Role of CNC Milling in Creating Superior CNC Milled Parts

CNC Freze is the foundation for producing high-quality CNC Frezelenmiş parçalar. It enables manufacturers to achieve intricate designs and fine details that are crucial for modern applications. This section explores how CNC Milling contributes to the production of durable and precise components.

Critical Advantages:

- Boyutsal Doğruluk: Ensures parts meet exact specifications.

- Surface Quality: Produces smooth finishes that often require little to no post-processing.

- Karmaşık Geometriler: Enables machining of parts with multiple curves and angles in a single setup.

For businesses requiring exceptional CNC Frezelenmiş parçalar, utilizing advanced CNC Milling techniques is vital. CNCRUSH’s extensive experience in precision metalworking guarantees that every part is produced with unmatched quality and precision.

4. CNC Milling Techniques in CNC Turned Parts Production for Enhanced Metalworking

Sırasında CNC Freze is renowned for its capabilities in subtractive manufacturing, it also plays a significant role in complementing CNC Tornalanmış parçalar production. By integrating both milling and turning processes, manufacturers can create hybrid components that benefit from the strengths of each technique.

Key Integration Strategies:

- Hybrid Machining: Combining milling and turning operations to produce components with complex features.

- Toolpath Optimizasyonu: Ensuring smooth transitions between milling and turning processes.

- Geliştirilmiş esneklik: Meeting diverse production needs by using a multi-process approach.

CNCRUSH’s dual expertise in producing both CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar allows them to offer comprehensive solutions that cover the entire spectrum of high-precision metalworking needs. This integration is particularly valuable for industries that demand intricate designs and robust performance.

5. The Advantages of CNC Milling for Metal Fabrication in Automotive and Machine Building

The automotive and machine building sectors require components that are both durable and precisely engineered. CNC Freze offers significant benefits in these industries by ensuring high repeatability, minimal deviations, and exceptional material integrity.

Industry Benefits:

- Structural Integrity: Milling produces parts that can withstand high stresses and strains.

- Özelleştirme: Tailored machining solutions meet unique design requirements.

- Yeterlik: Fast production cycles enable quick turnaround times for high-volume orders.

For automotive and machine building applications, partnering with a proficient CNC işleme hizmeti provider like CNCRUSH ensures that every part—from CNC Frezelenmiş parçalar ile CNC Tornalanmış parçalar—is manufactured to the highest quality standards.

6. CNC Milling vs. Traditional Manufacturing Methods: A Comparative Analysis

Comparing CNC Freze with traditional manufacturing methods highlights its transformative impact on metalworking. The following table summarizes the key differences and advantages:

Table 1: Traditional Manufacturing vs. CNC Milling

| Parametre | Geleneksel Yöntemler | CNC Freze |

|---|---|---|

| Kesinlik | Lower; relies on manual adjustments | High; automated with tight tolerances |

| Tekrarlanabilirlik | Inconsistent due to human error | Consistent and repeatable |

| Yüzey İşlemi | Often requires additional finishing | Superior finish with minimal post-processing |

| Üretim Hızı | Slower; multiple setups required | Faster; optimized for high-volume production |

| Esneklik | Limited to simpler geometries | Capable of complex, multi-dimensional designs |

This comparative analysis underscores why CNC Freze has become the industry standard for high-precision metal fabrication, delivering clear advantages in terms of accuracy, efficiency, and overall quality.

7. Enhancing CNC Machining Service with Advanced CNC Milling Technology

Modern CNC Freze technology integrates advanced features that significantly enhance the performance of CNC işleme hizmeti providers. These advancements drive improvements in efficiency, accuracy, and overall production capabilities.

Key Technological Advancements:

- Yüksek hızlı işleme (HSM): Enables rapid cutting speeds without compromising accuracy.

- Multi-Axis Control: Allows for the simultaneous movement of cutting tools along multiple axes, reducing setup times.

- Uyarlanabilir Kontrol Sistemleri: Utilize real-time feedback to adjust cutting parameters dynamically.

- Computer-Aided Design/Manufacturing (CAD/CAM): Streamlines the production process by integrating design and manufacturing workflows.

For companies that rely on high-quality CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar, these technological innovations ensure that production processes remain efficient and competitive. CNCRUSH’s investment in state-of-the-art CNC Milling technology reflects its commitment to delivering top-tier CNC işleme hizmeti çözümler.

8. CNC Milling: Key Challenges and How to Overcome Them in High-Precision Metalworking

Despite its many advantages, CNC Freze comes with its own set of challenges. These can include issues related to tool wear, thermal distortion, and programming complexities. Addressing these challenges is essential for maintaining high precision in metalworking.

Ortak Zorluklar:

- Tool Wear and Tear: Regular maintenance and the use of advanced coatings can mitigate tool degradation.

- Thermal Distortion: Implementing proper coolant systems and optimized cutting speeds helps control heat buildup.

- Programming Complexity: Utilizing advanced CAM software and experienced programmers ensures accurate tool paths.

- Material Variability: Different metals require tailored machining parameters to achieve optimal results.

By proactively addressing these challenges, manufacturers can achieve more consistent results and extend the longevity of their CNC Milling equipment. CNCRUSH’s robust quality control and maintenance practices ensure that potential issues are identified and resolved before they impact production.

9. Future Trends in CNC Milling: Innovation and Sustainability in Metalworking

geleceği CNC Freze is marked by rapid technological innovation and a growing focus on sustainable practices. Emerging trends are set to transform the way high-precision metalworking is performed, making production even more efficient and environmentally friendly.

Ortaya çıkan trendler:

- Yapay zeka ve makine öğrenimi: Predictive analytics to optimize tool paths and maintenance schedules.

- Dijital İkiz Teknolojisi: Virtual simulations of machining processes to preemptively identify and resolve issues.

- Eco-Friendly Machining: Techniques designed to reduce energy consumption and material waste.

- Hibrit Üretim: Combining CNC Milling with additive manufacturing (3D printing) for enhanced design flexibility.

CNCRUSH is committed to staying ahead of these trends by continuously updating its processes and equipment. As a leading CNC işleme hizmeti provider, CNCRUSH leverages the latest advancements to deliver innovative solutions for CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar, ensuring sustainable and cutting-edge production practices.

10. How to Choose the Right CNC Milling Partner: Insights from a Leading CNC Machining Service Provider

Selecting the right partner for high-precision CNC precision Milling is critical for achieving manufacturing excellence. Companies must evaluate potential partners based on several factors including experience, technological capabilities, and customer support.

Key Selection Criteria:

- Experience and Expertise: Look for providers with a proven track record in high-precision metalworking.

- İleri Teknoloji: Ensure the provider uses state-of-the-art CNC precision Milling machines and integrated CAM systems.

- Kalite Güvencesi: Certifications such as ISO and stringent quality control measures are essential.

- Özelleştirme Yetenekleri: The ability to produce tailored CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar for specific industry needs.

- Müşteri Geri Bildirimi: Positive testimonials and case studies from industries like automotive, machine building, and automotion.

CNCRUSH meets all these criteria with over 12 years of experience and a commitment to continuous improvement. Their comprehensive CNC işleme hizmeti covers everything from prototype development to full-scale production, ensuring that every component is manufactured to the highest standards.

Comparative Analysis: CNC Milling vs. Other CNC Machining Techniques

To illustrate the unique benefits of CNC Freze, the following tables offer a side-by-side comparison of CNC Milling with other common machining techniques.

Table 2: CNC Milling Compared to Other Techniques

| Parametre | CNC Freze | Other CNC Machining (e.g., Turning, 3-Axis) |

|---|---|---|

| Kesinlik | High; capable of complex geometries | Moderate; limited by fewer axes |

| Yüzey İşlemi | Excellent; minimal post-processing needed | Often requires additional finishing |

| Esneklik | Versatile; suitable for intricate designs | Less versatile; simpler geometries |

| Döngü Süresi | Optimized for high efficiency | Çoklu kurulumlar nedeniyle daha uzun |

| Tool Utilization | Advanced tool paths reduce wear | Higher wear and tear with repetitive cuts |

Table 3: Benefits of Partnering with CNCRUSH for CNC Milling

| Bakış açısı | General Providers | CNCRUSH Advantages |

|---|---|---|

| Deneyim | Değişken | 12+ years of high-precision expertise |

| Özelleştirme | Standardized solutions | Tailored CNC Milled parts and CNC Turned parts |

| Technological Integration | Basic CNC setups | State-of-the-art CNC Milling & Turning equipment |

| Kalite Kontrol | Inconsistent quality | Rigorous, ISO-certified quality protocols |

| Industry Compliance | Often limited | Comprehensive solutions for automotive, machine building, and automotion |

FAQ: CNC Milling in High-Precision Metalworking

Q1: What is CNC Milling and why is it important for metalworking?

A1: CNC Freze is a subtractive manufacturing process that uses rotating cutting tools to remove material from a workpiece. It is crucial for producing high-precision components with complex geometries and excellent surface finishes, making it essential in industries like aerospace, automotive, and machine building.

S2: CNC Frezeleme, CNC Frezelenmiş parçaların ve CNC Tornalanmış parçaların üretimini nasıl geliştirir?

A2: CNC Frezeleme, dar toleranslara sahip karmaşık tasarımların oluşturulmasını sağlayarak birden fazla kurulum ve ikincil son işlem ihtiyacını azaltır. CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar yüksek kalite ve hassasiyet standartlarını karşılamaktadır.

S3: CNC Frezeleme genel üretim maliyetlerini azaltabilir mi?

A3: Evet, CNC hassas Frezeleme daha yüksek bir ilk yatırıma sahip olsa da, kurulum sürelerini azaltma, malzeme israfını en aza indirme ve üretim verimliliğini artırma yeteneği, sonuçta yüksek hacimli üretimde genel maliyetleri düşürür.

S4: CNC Frezelemeden en çok hangi sektörler yararlanıyor?

A4: Havacılık, otomotiv, makine yapımı ve otomotiv gibi endüstriler, güvenlik ve performans için gerekli olan karmaşık, yüksek hassasiyetli bileşenleri üretme kabiliyeti nedeniyle CNC hassas Frezelemeden önemli ölçüde yararlanmaktadır.

S5: CNCRUSH'un CNC Frezeleme hizmetlerine nasıl başlayabilirim?

A5: Ziyaret CNCRUSH hakkında daha fazla bilgi edinmek için CNC işleme hizmeti için özel çözümler de dahil olmak üzere teklifler CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalarDeneyimli ekibimiz sürecin her adımında size rehberlik edecektir.

Sonuç: CNC Frezeleme Mükemmelliği ile Metal İşlemede Dönüşüm

Sonuç olarak, CNC Freze eşsiz doğruluk, verimlilik ve çok yönlülük sunarak yüksek hassasiyetli metal işlemede vazgeçilmez bir rol oynar. Bu teknoloji, havacılık ve otomotivden makine imalatına ve otomotive kadar modern endüstrilerin zorlu taleplerini karşılayan karmaşık bileşenlerin üretilmesini sağlar. Bu kılavuzda ele alınan bilgiler, temel süreçlerini anlamaktan gelişmiş teknolojilerden yararlanmaya ve yaygın zorlukların üstesinden gelmeye kadar CNC hassas Frezelemede ustalaşmanın 10 güçlü sırrını vurgulamaktadır.

Üreticiler, CNCRUSH gibi güvenilir bir sağlayıcı ile ortaklık kurarak uzmanlara erişim kazanırlar CNC işleme hizmeti üstün performans sunan CNC Frezelenmiş parçalar Ve CNC Tornalanmış parçalar Özel üretim ihtiyaçlarına göre uyarlanmıştır. 12 yılı aşkın deneyimi ve kaliteye olan bağlılığı ile CNCRUSH, metal imalatında yenilik ve mükemmelliği teşvik etmeye kendini adamıştır.

Gelişmiş CNC hassas Frezeleme teknolojisi ile yüksek hassasiyetli metal işlemenin geleceğini kucaklayın. Her seferinde olağanüstü sonuçlar veren son teknoloji çözümlerle avantajları keşfedin, zorlukların üstesinden gelin ve üretim sürecinizi dönüştürün. CNCRUSH'ın üretim kapasitenizi nasıl artırabileceği hakkında daha fazla bilgi için şu adresi ziyaret edin CNCRUSH bugün ve gerçek hassasiyetin yaratabileceği farkı keşfedin.