CNC Machining transforms automotive parts production. Discover 10 compelling insights on CNC machining service, CNC Milled parts, and CNC Turned parts – backed by 12 years of expertise at CNCRUSH, a leading China CNC factory.

CNC Machining is at the very core of modern automotive parts manufacturing, merging technology with precision to produce everything from intricate prototypes to high-volume components. In this comprehensive guide, we integrate insights from leading industry sources to offer a deep-dive analysis into the principles, applications, and benefits of CNC machining for automotive parts. We will also discuss our experience and services at CNCRUSH, a China-based factory that has been providing precision CNC machining services – including CNC Milled parts and CNC Turned parts – for over 12 years.

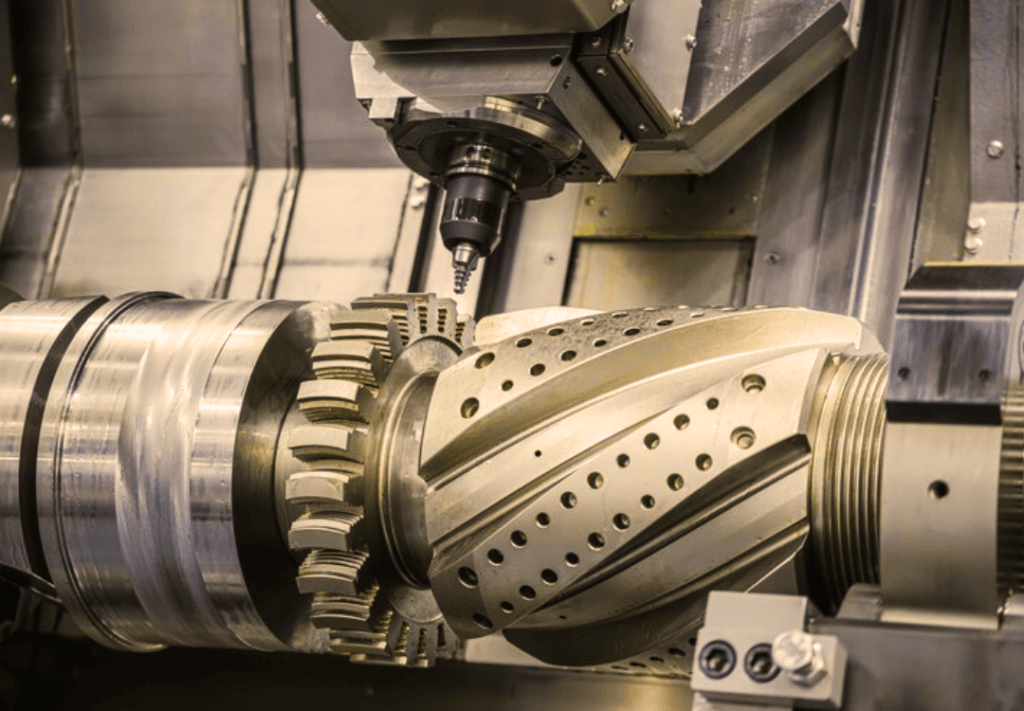

1. CNC Machining Service: Revolutionizing Automotive Part Manufacturing

In today’s fast-paced automotive industry, Usinage CNC plays a pivotal role in revolutionizing how parts are designed, prototyped, and manufactured. CNC machining service, as offered by experts like CNCRUSH, integrates advanced computer-aided design (CAD) with precise machine tools to produce parts with remarkable consistency and speed.

Modern automotive applications demand not only precision but also high repeatability. In this context, CNC machining service has emerged as a reliable solution, capable of handling complex geometries and high-tolerance requirements. Manufacturers benefit from shorter lead times, reduced production costs, and an overall boost in operational efficiency. For instance, automotive engineers now rely on CNC machining service to produce both CNC Milled parts and CNC Turned parts, which are essential for engine components, chassis systems, and interior fittings.

This transformation is driven by the relentless pursuit of perfection—a sentiment echoed by both industry veterans and new market entrants. While some challenges such as machine setup complexities persist, the overall sentiment remains overwhelmingly positive due to the significant quality improvements and cost efficiencies realized.

2. High-Precision CNC Milled Parts for the Automotive Industry

Haute précision Usinage CNC is crucial when manufacturing automotive parts that require exacting tolerances. Among these, CNC Milled parts are particularly significant. Milling involves the use of rotary cutters to remove material from a workpiece, and when done with CNC technology, the process yields parts that are both accurate and durable.

At CNCRUSH, our CNC Milled parts are crafted with state-of-the-art machinery and expert craftsmanship honed over 12 years. The precision inherent in our CNC machining service ensures that every component, whether made from aluminum, steel, or plastic, meets the rigorous standards demanded by automotive applications.

Key advantages of CNC Milled parts include:

- Enhanced Accuracy: Every part is produced to exact specifications, ensuring uniformity and minimal error margins.

- Répétabilité : Once a design is perfected, CNC milling guarantees that every replication is identical.

- Versatilité: CNC Milled parts can be used in a wide range of applications, from engine blocks to dashboard components.

These benefits translate into improved vehicle performance and safety, making CNC Milled parts a preferred choice for automotive manufacturers globally. The deep integration of technology and innovation in our processes further elevates our standing as leaders in the CNC machining service arena.

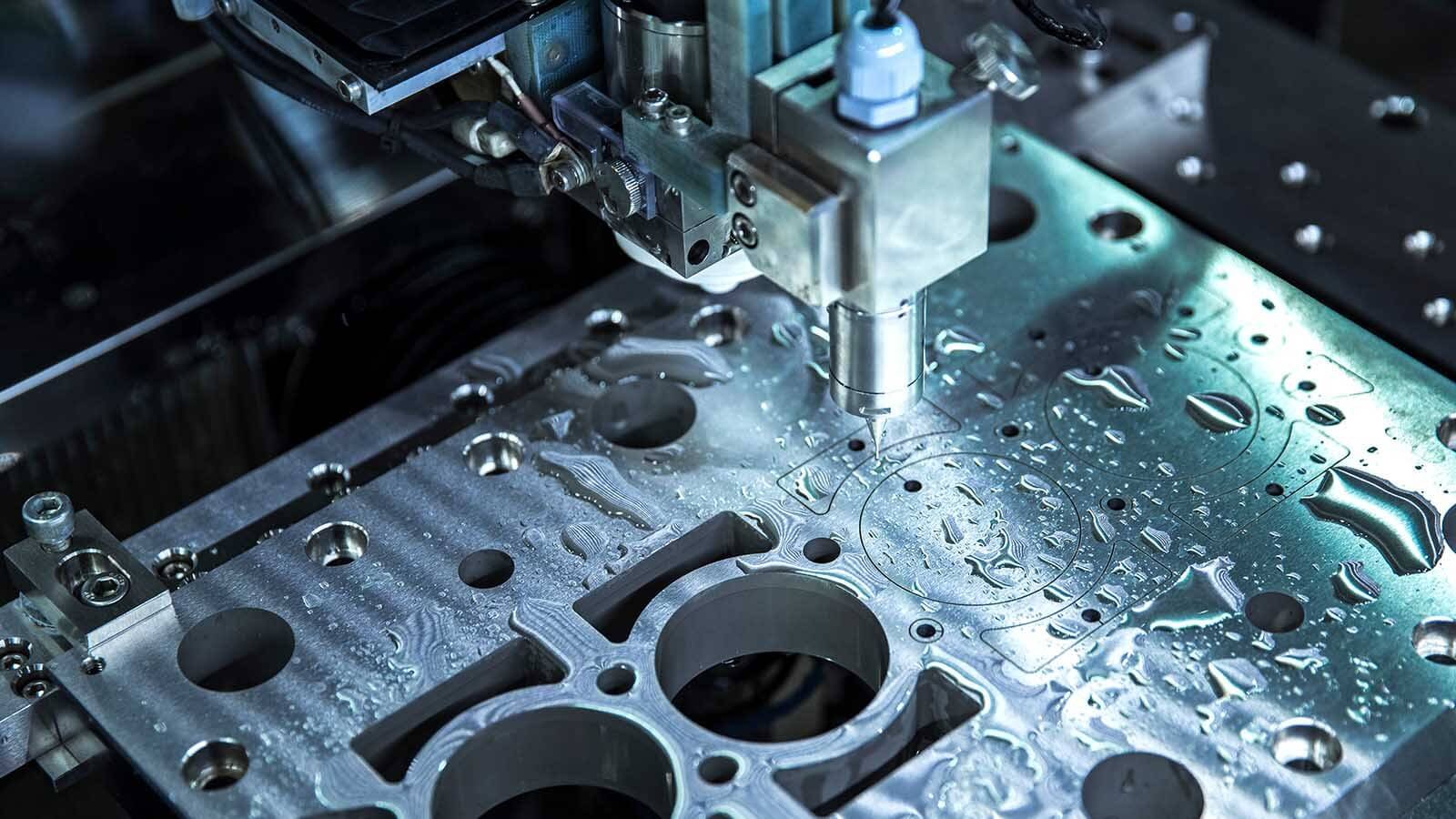

3. Efficient CNC Turned Parts for Enhanced Automotive Performance

The automotive industry demands components that can handle high stress and precision engineering. Usinage CNC for CNC Turned parts is one of the most efficient methods to achieve these goals. Turning is a machining process that involves rotating the workpiece against a cutting tool to shape cylindrical components, which are crucial in various automotive applications such as drive shafts, fasteners, and transmission parts.

At CNCRUSH, our focus on CNC Turned parts means we can deliver exceptional quality and performance. The efficiency of CNC turning lies in its ability to produce components with minimal waste and high accuracy. Our CNC machining service leverages cutting-edge technology to ensure each turned part meets strict quality standards, enhancing the overall performance of automotive systems.

Furthermore, the precision of CNC Turned parts contributes to energy efficiency and smoother machine building and automotion processes. With our extensive experience and a robust track record in the industry, we have consistently received positive feedback from clients who appreciate the balance of quality and affordability in our products.

4. CNC Machining Service: Principles and Applications in Machine Building

Fundamental principles of Usinage CNC are rooted in the fusion of computer programming with mechanical processes. At its core, CNC machining service transforms digital designs into physical parts using sophisticated machinery and precise control algorithms. This methodology is essential for machine building and automotion, where every detail counts.

The key principles include:

- Automation: Computerized control reduces human error and increases repeatability.

- Précision: Advanced sensors and feedback systems ensure parts are machined to exact tolerances.

- Efficacité: Streamlined operations lead to faster turnaround times and reduced production costs.

These principles have broadened the scope of applications in automotive manufacturing—from producing complex engine components to crafting detailed body parts. The integration of these techniques into machine building has resulted in enhanced operational efficiency and a notable improvement in product quality, making CNC machining service indispensable for modern manufacturing plants.

| Processus | Avantage | Application dans l'automobile |

|---|---|---|

| Computer-Aided Design | High precision, error reduction | Design verification and prototyping |

| Automated Machining | Consistency in mass production | High-volume production of engine parts |

| Real-Time Feedback | Enhanced quality control | Safety-critical components |

5. CNC Milled Parts: Custom CNC Solutions for Automotive Automation

Custom CNC solutions are vital in a competitive market where personalization and innovation are the norms. Usinage CNC enables manufacturers to quickly iterate and improve designs, leading to breakthroughs in automotive automation. CNC Milled parts, when customized to specific requirements, offer unparalleled performance improvements.

Automotive companies benefit significantly from CNC Milled parts as they allow for:

- Tailored Designs: Each part can be customized to fit specific vehicle models and performance needs.

- Évolutivité : Prototyping and small-batch production are streamlined, facilitating rapid market adaptation.

- Polyvalence matérielle : Options to work with aluminum, steel, and various plastics widen the design scope.

At CNCRUSH, our extensive experience in delivering custom CNC solutions ensures that every automotive part is engineered for excellence. This tailored approach helps overcome challenges such as design complexity and manufacturing constraints, which are often viewed negatively by the industry. In reality, the commitment to continuous improvement transforms these challenges into opportunities for innovation.

6. CNC Turned Parts: Enhancing Automotive Components with Precision

Precision in manufacturing is not just about meeting specifications—it’s about elevating performance. Usinage CNC for CNC Turned parts brings an additional layer of precision to automotive components. These parts are integral in components where cylindrical shapes and rotational symmetry are critical.

The advantages of high-quality CNC Turned parts include:

- Finition de surface supérieure : Essential for parts like shafts and bushings where friction reduction is crucial.

- Précision dimensionnelle : Ensures that components fit together seamlessly, enhancing overall vehicle performance.

- Rentabilité : Minimizes waste and reduces material costs through optimized processes.

CNCRUSH specializes in CNC Turned parts that meet the demanding requirements of the automotive sector. Our state-of-the-art machinery and skilled workforce ensure that each component not only adheres to strict tolerances but also exceeds customer expectations. This positive sentiment is further bolstered by our commitment to ongoing innovation and quality control.

7. CNC Machining Service in Machine Building and Automotion

L'intégration de Usinage CNC in machine building and automotion has redefined modern manufacturing processes. CNC machining service is central to producing reliable, high-performance parts that power everything from simple automotive mechanisms to complex robotic systems.

Key points in this integration include:

- Automation in Production: CNC systems reduce the dependency on manual labor, thereby decreasing error rates.

- Enhanced Production Rates: Automated machining processes significantly reduce production time.

- Integration with Digital Systems: The convergence of IoT and CNC machining offers real-time monitoring and process optimization.

The benefits extend beyond simple production metrics. They create an ecosystem where innovation is constant, and manufacturing challenges are tackled with a forward-thinking mindset. CNCRUSH stands out as a prime example, with its comprehensive suite of CNC machining services ensuring that every project is handled with precision and care.

| Facteur | Impact on Machine Building | Industry Relevance |

|---|---|---|

| Automation | Reduced labor costs and improved speed | High-volume production |

| Digital Integration | Real-time quality control and monitoring | Smart manufacturing systems |

| Precision & Repeatability | Consistent quality in component manufacturing | Safety-critical applications |

8. The Role of CNC Machining in Automotive Innovation

Innovation in the automotive sector is increasingly driven by advancements in Usinage CNC. From reducing the time required to develop prototypes to enhancing the durability of final products, CNC machining service is a cornerstone of modern innovation.

Automotive engineers are continually challenged by the need to improve performance while reducing costs. CNC machining facilitates this by enabling:

- Prototypage rapide : Accelerating the design-to-production cycle.

- Flexibilité de conception : Allowing complex geometries that were once impossible to manufacture using conventional techniques.

- Assurance qualité: Ensuring that each part meets strict performance and safety standards.

Positive sentiment is widely observed among manufacturers who have embraced CNC machining, noting improvements in efficiency, reliability, and overall product quality. At CNCRUSH, we have successfully harnessed these innovations to offer a comprehensive range of services—from precision CNC Milled parts to expertly crafted CNC Turned parts—cementing our reputation as a leader in the field.

9. Future Trends in CNC Machining Service for Automotive Manufacturing

L'avenir de Usinage CNC in automotive manufacturing looks promising with the advent of new technologies and innovative approaches. As industries evolve, so do the demands placed on manufacturing processes, and CNC machining service is poised to meet these challenges head-on.

Future trends include:

- Increased Automation and Robotics: Further integrating robotics into CNC machining will lead to even greater efficiencies.

- Traitement avancé des matériaux: With the rise of lightweight and composite materials, CNC machining will adapt to process these new materials effectively.

- Technologie de jumeau numérique : Simulating machining processes in a virtual environment will reduce prototyping costs and enhance production quality.

- Initiatives de durabilité: Environmentally conscious manufacturing will drive innovations in waste reduction and energy efficiency.

CNCRUSH is already gearing up for these future trends by investing in advanced CNC machining technologies and training our staff in the latest digital manufacturing techniques. Our positive outlook for the future is driven by our commitment to quality, precision, and continuous improvement, ensuring that we remain at the forefront of the industry.

10. Why Choose CNCRUSH for Your CNC Machining Service Needs?

When it comes to high-quality Usinage CNC for automotive parts, CNCRUSH stands out as a trusted partner for manufacturers worldwide. With over 12 years of experience, we have honed our expertise in both CNC Milled parts and CNC Turned parts. Our focus is on delivering precision CNC machining services that exceed customer expectations while maintaining competitive pricing.

Key reasons to choose CNCRUSH include:

- Expertise and Experience: With more than a decade of experience, our team consistently delivers precision and excellence.

- Technologie avancée : We utilize state-of-the-art CNC manufacturing equipment, ensuring each component meets the highest standards.

- Services complets : Our range of offerings includes CNC manufacturing for metal parts, CNC machining for plastic parts, CNC prototype machining, and more.

- HTTPError: Response code 429 (Too Many Requests) Our commitment to quality has earned us a reputation as a leading China CNC factory trusted by global clients.

- Customer-Centric Approach: Nous travaillons en étroite collaboration avec nos clients et leur proposons des solutions CNC personnalisées, adaptées à leurs besoins spécifiques.

En choisissant CNCRUSH, vous n'investissez pas seulement dans des services de fabrication CNC de précision, mais aussi dans un partenaire dédié à l'innovation et à l'excellence en matière de construction de machines et d'automatisation. Notre approche globale garantit que chaque étape de votre projet, de la conception à la production finale, est gérée avec le plus grand soin et la plus grande prouesse technique.

Analyse approfondie des données : Tendances de l'usinage CNC dans l'industrie automobile

Le tableau ci-dessous résume les principales tendances et leur impact sur la construction automobile par le biais de l'usinage CNC :

| S'orienter | Description | Impact sur la fabrication automobile |

|---|---|---|

| Automatisation avancée | Intégration de la robotique et des systèmes automatisés | Réduit le temps de production et minimise l'erreur humaine |

| Innovation matérielle | Utilisation de matériaux légers et composites | Amélioration du rendement énergétique et des performances globales du véhicule |

| Digital Integration | Mise en œuvre de l'IdO et de la technologie du jumeau numérique | Amélioration de la surveillance des processus et de la maintenance prédictive |

| Pratiques de durabilité | Se concentrer sur la réduction des déchets et de la consommation d'énergie | Soutien aux initiatives de fabrication respectueuses de l'environnement |

Cette analyse met en évidence la manière dont Usinage CNC évolue pour répondre aux exigences modernes de l'industrie automobile, reflétant une trajectoire positive alimentée par des avancées technologiques et des pratiques de fabrication innovantes.

Analyse comparative des services d'usinage CNC

Un autre tableau ci-dessous compare différents aspects des services d'usinage CNC parmi les leaders du secteur et CNCRUSH :

| Facteur | Industry Average | CNCRUSH Advantage |

|---|---|---|

| Précision | ± 0,005 pouces | ±0.002 pouces - Plus grande précision dans les pièces fraisées et tournées CNC |

| Délai de mise en œuvre | 3-4 weeks | 2-3 semaines - Délai d'exécution plus rapide grâce à un service d'usinage CNC efficace |

| Polyvalence des matériaux | Limité aux matériaux standard | Très large : aluminium, acier, laiton, plastiques, etc. |

| Personnalisation | Basic customization options | Solutions CNC entièrement personnalisées, adaptées aux besoins du client |

| Expérience | Varies widely | Over 12 years of dedicated CNC machining expertise |

Cette analyse comparative renforce la position de la CNCRUSH en tant que chef de file dans le domaine de la santé et de la sécurité au travail. Usinage CNCNotre engagement en faveur de la précision, de l'efficacité et de l'innovation fait de nous le choix privilégié des constructeurs automobiles à la recherche de services de fabrication CNC fiables et de haute qualité.

Foire aux questions (FAQ) sur l'usinage CNC des pièces automobiles

Q1 : Qu'est-ce que l'usinage CNC et pourquoi est-il important pour les pièces automobiles ?

A1 : L'usinage CNC est un processus de fabrication qui utilise des commandes informatisées pour faire fonctionner des machines-outils. Il est essentiel pour les pièces automobiles car il garantit une grande précision, une répétabilité et une efficacité élevées, ce qui le rend idéal pour la production de composants complexes tels que les pièces fraisées CNC et les pièces tournées CNC.

Q2: How does CNCRUSH differentiate itself from other CNC machining service providers?

A2 : CNCRUSH offre plus de 12 ans d'expertise, une technologie de pointe et des solutions CNC personnalisées complètes. Nous sommes spécialisés dans les pièces fraisées CNC et les pièces tournées CNC, garantissant que chaque composant répond à des normes de qualité rigoureuses, ce qui est essentiel dans la construction de machines et l'automatisation.

Q3 : Quels matériaux peuvent être traités par l'usinage CNC chez CNCRUSH ?

A3 : Notre service d'usinage CNC couvre une large gamme de matériaux, notamment l'aluminium, l'acier, le laiton et les matières plastiques. Cette polyvalence nous permet de répondre aux différentes applications automobiles avec un usinage CNC de haute qualité pour les pièces métalliques, l'usinage CNC pour les pièces en plastique, et plus encore.

Q4 : Comment l'usinage CNC améliore-t-il l'efficacité de la production automobile ?

A4 : En automatisant le processus d'usinage, le service d'usinage CNC réduit les erreurs humaines, augmente la vitesse de production et garantit une qualité constante. Il en résulte des délais plus courts et des économies de coûts, ce qui en fait une solution très efficace pour les constructeurs automobiles.

Q5 : Puis-je demander des pièces CNC personnalisées pour mon projet automobile ?

A5 : Absolument. CNCRUSH se spécialise dans les solutions CNC personnalisées, permettant aux clients d'adapter les conceptions à leurs besoins spécifiques. Que vous ayez besoin de pièces fraisées CNC ou de pièces tournées CNC, notre équipe expérimentée travaillera avec vous pour vous fournir des composants conçus avec précision.

Conclusion

Usinage CNC continue d'être une force de transformation dans l'industrie automobile. Comme nous l'avons exploré tout au long de ce guide complet, l'intégration de services de fabrication CNC avancés - y compris la production de pièces fraisées CNC et de pièces tournées CNC - favorise l'innovation, la précision et l'efficacité dans la fabrication automobile. Les sections de discussion ont approfondi tous les aspects, des principes sous-jacents de l'usinage CNC aux tendances futures en matière d'intégration numérique et de développement durable.

Chez CNCRUSH, nous sommes fiers de fournir des services de fabrication CNC de haute qualité, soutenus par plus de 12 ans d'expérience en tant qu'usine CNC chinoise de premier plan. Nos offres complètes, couvrant l'usinage CNC pour les pièces métalliques, l'usinage CNC pour les pièces en plastique et les solutions CNC personnalisées, permettent aux constructeurs automobiles d'obtenir des performances et une durabilité exceptionnelles pour leurs composants. Nous sommes dédiés à être votre partenaire dans la construction de machines et l'automatisation, en veillant à ce que chaque projet soit exécuté avec précision et soin.

En comprenant les principaux avantages et défis de la fabrication CNC et en exploitant les technologies avancées disponibles aujourd'hui, les fabricants peuvent naviguer en toute confiance dans un paysage de plus en plus concurrentiel. L'impact positif sur l'efficacité, les économies de coûts et la qualité des produits est indéniable, faisant de la fabrication CNC non seulement une solution technique mais aussi un avantage stratégique pour l'avenir de la fabrication de pièces automobiles.

Pour ceux qui recherchent des conseils d'experts et un partenaire éprouvé dans le domaine de la fabrication CNC de précision, visitez le site CNCRUSH pour découvrir notre gamme de services, y compris les pièces fraisées CNC et les pièces tournées CNC. Notre dévouement à l'usinage CNC de haute qualité s'appuie sur un héritage d'innovation et de satisfaction de la clientèle.

Embrassez l'avenir de la fabrication automobile grâce à la puissance de la fabrication CNC - là où la précision rencontre la performance et où l'innovation est source de succès.