CNC Machining for Automotive Components has revolutionized the automotive industry, offering unparalleled precision and efficiency. Drawing insights from leading industry sources, this article delves into the transformative impact of CNC machining on automotive manufacturing. From the evolution of CNC technology to its role in producing critical automotive parts, we explore ten key areas that highlight the significance of CNC machining in the automotive sector. Additionally, we introduce CNCRUSH, a trusted provider of high-quality CNC machining services, specializing in CNC Milled parts and CNC Turned parts, with over 12 years of experience in the field.

1. The Evolution of CNC Machining in Automotive Manufacturing

The journey of CNC machining in the automotive industry has been marked by significant technological advancements. From its inception as a tool for basic component fabrication, CNC machining has evolved into a sophisticated process capable of producing complex automotive parts with high precision. Cette évolution a été entraînée par la demande de l'industrie d'améliorer les performances, la sécurité et l'efficacité des véhicules.

2. The Role of CNC Milled Parts in Automotive Applications

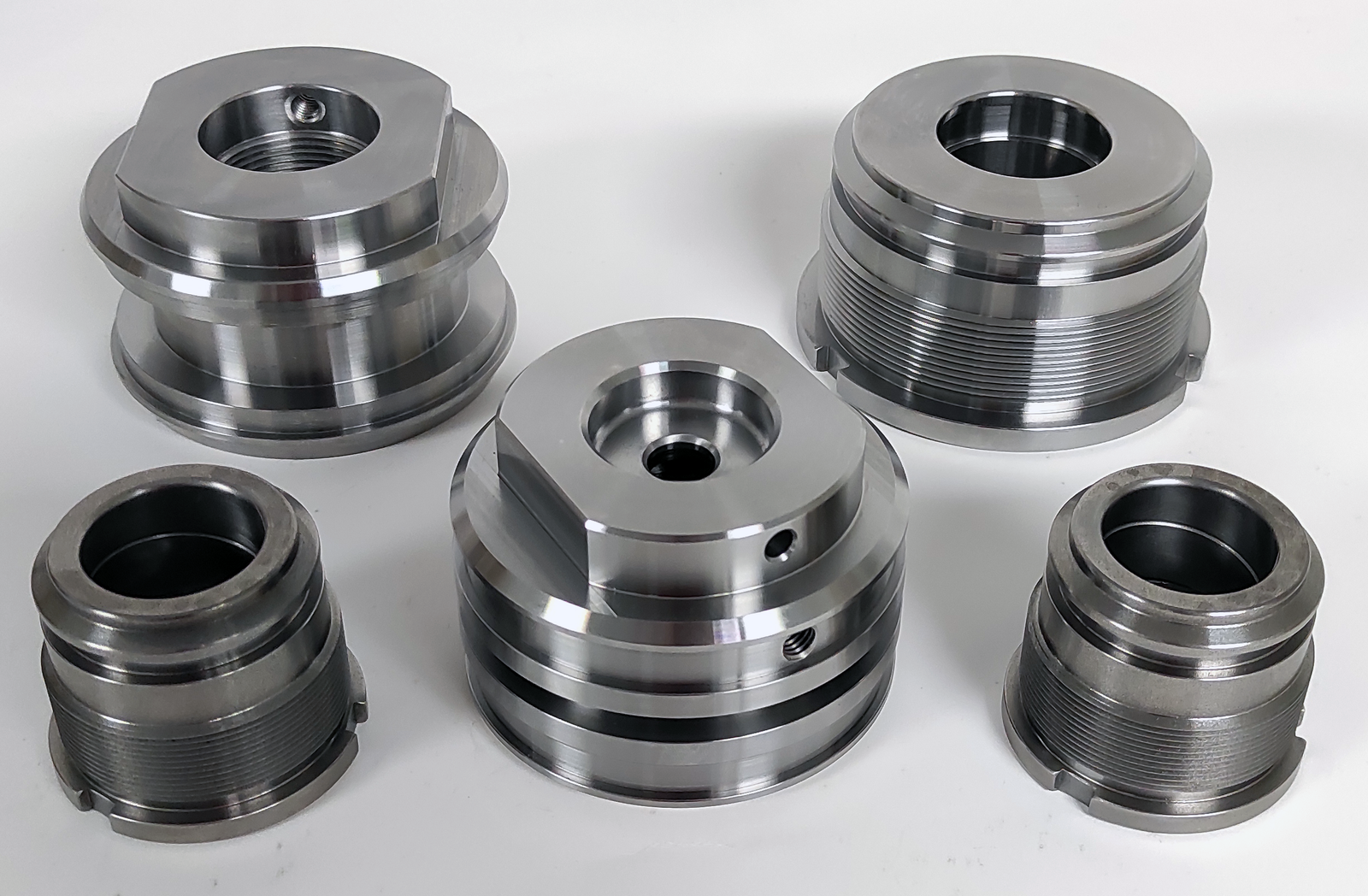

CNC Milled parts are integral to automotive manufacturing, offering precision and consistency in producing components such as engine blocks, transmission housings, and suspension parts. The milling process allows for intricate designs and tight tolerances, ensuring optimal performance and reliability in automotive applications.

3. CNC Turned Parts: Enhancing Automotive Component Precision

CNC Turned parts play a crucial role in the automotive industry, particularly in the production of cylindrical components like shafts, pins, and bushings. The turning process provides high accuracy and surface finish, essential for parts that require rotational symmetry and tight dimensional control.

4. Material Selection in CNC Machining for Automotive Components

Selecting the appropriate material is vital in CNC machining for automotive components. Common materials include aluminum, steel, and various plastics, each offering specific properties suited to different applications. Le choix du matériau a un impact sur la résistance, le poids et la résistance du composant aux facteurs environnementaux.

5. Quality Control and Inspection in CNC Machining

Ensuring the quality of CNC machined automotive components is paramount. Advanced inspection techniques, such as coordinate measuring machines (CMM) and laser scanning, are employed to verify dimensional accuracy and surface integrity. These quality control measures are critical in maintaining the high standards required in the automotive industry.

6. The Impact of CNC Machining on Automotive Innovation

CNC machining has significantly contributed to innovation in the automotive sector. By enabling the production of complex and lightweight components, it supports the development of fuel-efficient and high-performance vehicles. Additionally, CNC precision machining facilitates rapid prototyping, accelerating the design and testing of new automotive technologies.

7. CNC Machining and Industrial Automation in Automotive Manufacturing

The integration of CNC machining with industrial automation has transformed automotive manufacturing processes. Automated CNC machines operate with minimal human intervention, increasing production efficiency and consistency. This synergy enhances the scalability of manufacturing operations and reduces lead times.

8. Challenges in CNC Machining for Automotive Components

Despite its advantages, CNC precision machining in the automotive industry faces challenges such as high initial investment costs, the need for skilled operators, and the complexity of programming for intricate parts. Addressing these challenges requires ongoing training, investment in advanced machinery, and continuous process optimization.

9. Future Trends in CNC Machining for Automotive Applications

Emerging trends in CNC precision machining for the automotive industry include the adoption of multi-axis machines, the use of advanced materials, and the integration of artificial intelligence for predictive maintenance. These developments aim to further enhance precision, reduce production costs, and improve overall manufacturing efficiency.

10. CNCRUSH: Your Partner in High-Quality CNC Machining Services

At CNCRUSH, we specialize in providing high-precision CNC precision machining services for the automotive industry. With over 12 years of experience, our factory in China is equipped with state-of-the-art machinery to deliver top-quality CNC Milled parts and CNC Turned parts. Our commitment to excellence ensures that we meet the stringent requirements of our clients in the automotive, machine building, and automation sectors.

Comparative Analysis: CNC Milled vs. CNC Turned Parts

| Fonctionnalité | Pièces fraisées CNC | Pièces tournées CNC |

|---|---|---|

| Mouvement principal | Rotating cutting tool | Rotating workpiece |

| Suitable Geometries | Complex, non-cylindrical shapes | Cylindrical, symmetrical shapes |

| Applications typiques | Engine blocks, brackets, housings | Shafts, pins, bushings |

| Finition de surface | High-quality finish on flat surfaces | Superior finish on round surfaces |

| Efficacité de production | Effective for complex, low-volume parts | Ideal for high-volume, uniform parts |

Material Suitability for Automotive CNC Machining

| Matériel | Propriétés | Applications courantes |

|---|---|---|

| Aluminium | Léger, résistant à la corrosion | Engine components, transmission cases |

| Acier | Haute résistance, durabilité | Structural parts, suspension components |

| Plastiques | Lightweight, chemical-resistant | Interior components, electrical housings |

Foire aux questions (FAQ)

Q1: What is CNC machining, and how is it used in the automotive industry?

A1 : L'usinage de précision CNC est un processus de fabrication qui utilise des machines contrôlées par ordinateur pour produire des composants précis. Dans l'industrie automobile, il est utilisé pour créer des pièces telles que des blocs moteurs, des carter de transmission et des composants de suspension avec une grande précision et une grande cohérence.

Q2: What are the advantages of CNC Milled parts in automotive applications?

A2: CNC Milled parts offer high precision, the ability to produce complex geometries, and excellent surface finishes, making them ideal for critical automotive components.

Q3: How do CNC Turned parts benefit automotive manufacturing?

A3: CNC Turned parts are essential for producing cylindrical components with tight tolerances and smooth finishes, such as shafts and bushings, ensuring optimal performance in automotive systems.

Q4: Why is material selection important in CNC precision machining for automotive components?

A4: Choosing the right material affects the strength, weight, and durability of automotive parts. Materials like aluminum and steel are commonly used for their specific properties suited to different applications.

Q5: How does CNCRUSH ensure the quality of its CNC machined automotive parts?

A5: CNCRUSH employs advanced inspection techniques and strict quality control processes to ensure that all CNC machined parts meet the highest standards required in the automotive industry.

For more information on our CNC machining services and to discuss your automotive component needs, visit CNCRUSH.