Fraisage CNC has become a cornerstone in the world of modern metalworking. CNC Milling technology enhances efficiency, reduces error, and boosts consistency, making it a fundamental part of manufacturing across sectors like automobile, construction de machines et automatisation. In this article, we explore how CNC milling improves metalworking efficiency, based on a deep analysis of top industry resources and search intent behind high-traffic content. The goal is to provide comparative insights, digestible explanations for general manufacturers, and a clear path to reliable production results through service d'usinage CNC like CNCRUSH.

CNCRUSH, a China-based manufacturer with over 12 years of experience, specializes in Pièces fraisées CNC et Pièces tournées CNCNous servons des clients mondiaux dans divers secteurs en offrant la précision, l'abordabilité et le professionnalisme. Si vous cherchez un partenaire de confiance service d'usinage CNC provider, CNCRUSH is your solution.

1. CNC Milling and Efficiency: A Game-Changer for the Metalworking Industry

Modern manufacturers face constant pressure to improve productivity without compromising quality. CNC Milling improves metalworking efficiency through automation, allowing faster cycle times, less downtime, and more predictable output.

- Traditional machining methods rely heavily on manual operation, introducing variation and longer turnaround.

- With CNC milling, once a program is optimized, it can be replicated across thousands of parts without variation.

Positive sentiment: This consistency provides manufacturers peace of mind, ensuring that delivery deadlines are met without costly rework.

2. The Role of CNC Machining Service in Reducing Production Time

A reliable service d'usinage CNC cuts down the setup time dramatically.

- Tools are automatically selected and changed.

- Operations can be completed without stopping the machine.

- Multi-axis capabilities (3-axis, 4-axis, 5-axis) reduce the number of setups.

Table 1: Traditional vs CNC Machining Time Comparison

| Opération | Traditional Setup Time | CNC Setup Time |

|---|---|---|

| Single Milling Pass | 20 min | 5 min |

| Tool Change | Manual, 10 min | Automatic, 1 min |

| Position Adjustments | Manual, 30 min | Digital, 3 min |

Result: CNC technology reduces up to 70% of setup time, allowing production to scale rapidly.

3. How CNC Milled Parts Improve Dimensional Precision

CNC Milling offers tolerances down to ±0.001mm. This is vital for sectors like automobile et construction de machines, where even the slightest deviation can lead to mechanical failure.

- Built-in feedback systems allow for real-time monitoring.

- Toolpath optimization ensures consistent material removal.

Positive sentiment: Dimensional precision not only minimizes waste but also builds customer trust.

4. CNC Turned Parts: Faster Cycle Times for Symmetrical Components

When speed matters, Pièces tournées CNC shine in delivering efficient results.

- Ideal for cylindrical or round components.

- CNC turning reduces material handling.

- Live tooling adds milling operations on a lathe, reducing steps.

Example: For a metal rod part requiring slots and threading, CNC turning with live tooling combines both operations in one cycle, halving production time.

5. Reduced Waste: How CNC Milling Minimizes Material Usage

Efficient tool paths, precise cuts, and nesting strategies in Fraisage CNC reduce scrap.

- CAM software simulates the cut before machining.

- Smart machining avoids overcuts and redundant paths.

- Higher material yield = reduced cost.

Table 2: Material Utilization Rates

| Type de processus | Utilisation des matériaux |

|---|---|

| Usinage manuel | ~65% |

| Fraisage CNC | ~90% |

Positive sentiment: Material conservation is both eco-friendly and cost-effective.

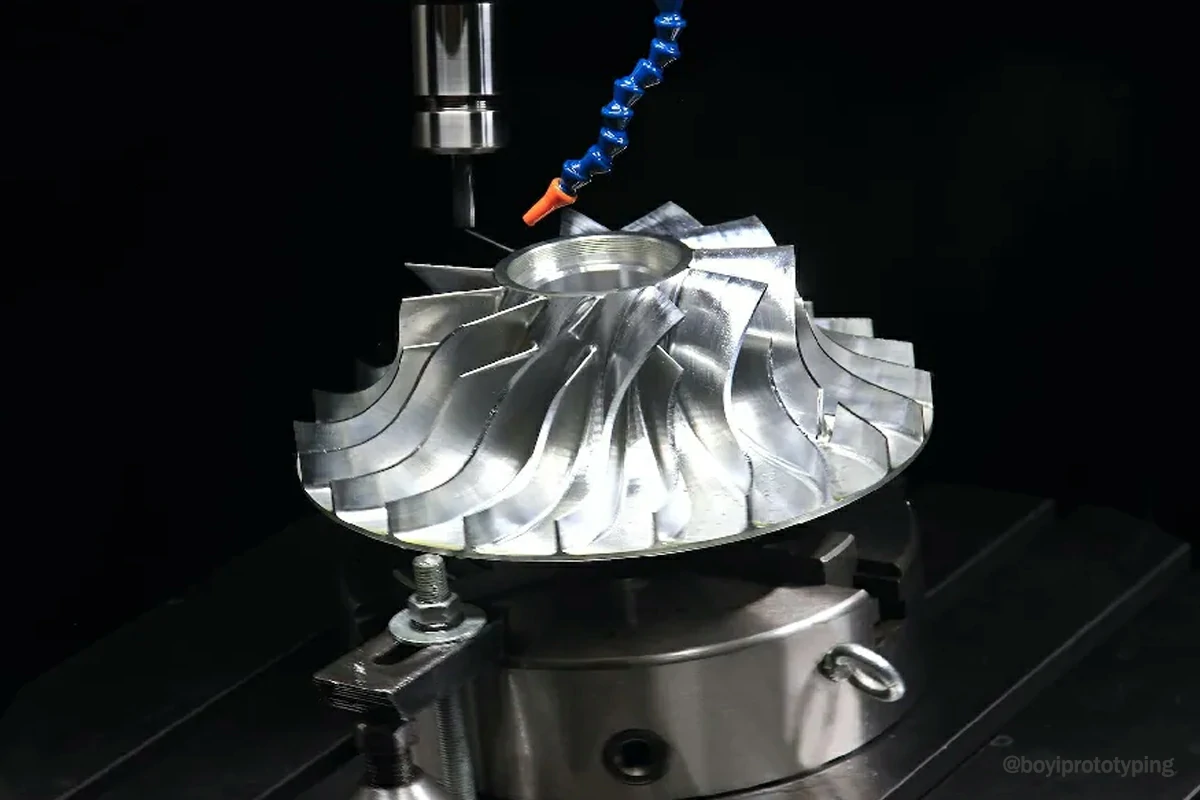

6. CNC Machining Service for Complex Geometries

Intricate parts for automation systems require complex tool paths and tight tolerances. A professional service d'usinage CNC like CNCRUSH utilizes:

- 5-axis milling for multi-directional access.

- Fixture design for stability.

- Simulation to detect and resolve tool conflicts before production.

This ensures the manufacture of parts previously impossible or expensive to produce manually.

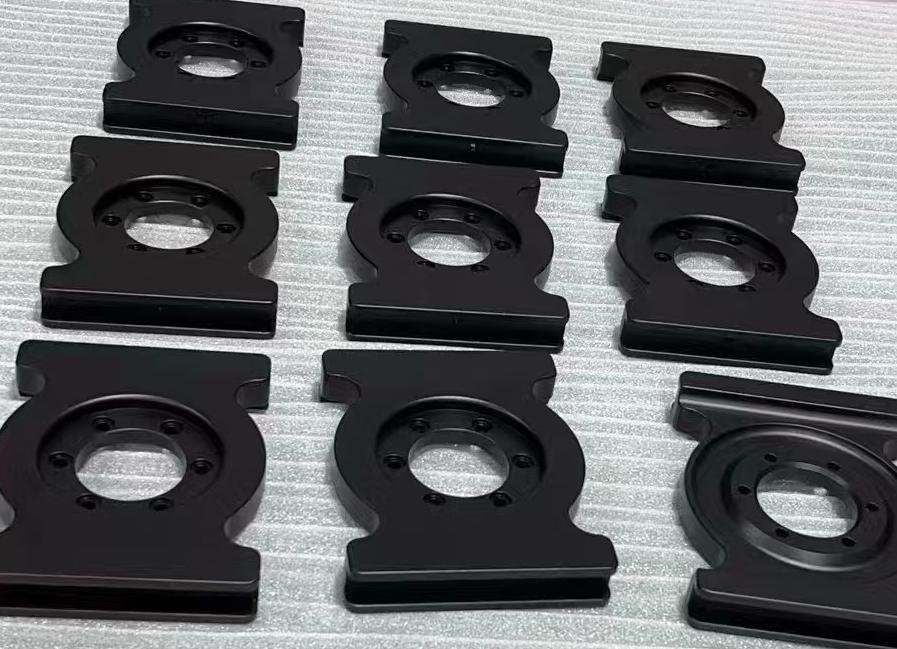

7. Scalability and Reproducibility with CNC Milled Parts

Scaling from prototype to production without changing the setup is a strong benefit of Pièces fraisées CNC:

- The digital file acts as a master.

- Every part remains consistent across 10 or 10,000 units.

This reliability allows manufacturers to confidently plan inventory and deliveries.

8. CNC Turned Parts and Labor Efficiency

Pièces tournées CNC reduce the need for human intervention:

- Automatic bar feeders load raw material.

- Robots unload finished parts.

Positive sentiment: Labor can be reassigned to higher-value tasks, boosting morale and reducing operational fatigue.

9. Error Reduction in Metalworking Through CNC Milling

Mistakes in metalworking can be expensive. CNC systems integrate fail-safes:

- Tool wear detection sensors.

- Collision prevention.

- Real-time error reporting.

These controls significantly reduce rework and ensure high First Pass Yield (FPY), critical for sectors like automobile.

10. Global Competitiveness Through CNC Machining Service in China

China-based providers like CNCRUSH offer cost-competitive, high-quality service d'usinage CNC to US and European customers:

- 12 ans d'expérience.

- Advanced inspection tools (CMM, height gauges, hardness testers).

- Proven quality in Pièces fraisées CNC et Pièces tournées CNC.

Positive sentiment: With global supply chain volatility, CNCRUSH ensures continuity, quality, and reliable pricing.

Foire aux questions (FAQ)

Q1: What industries benefit the most from CNC milling?

A1: Industries like automotive, aerospace, automation, and machine building benefit from CNC milling due to its precision and scalability.

Q2: Why should I choose CNCRUSH for CNC machining service?

A2: CNCRUSH has over 12 years of CNC machining experience, offers competitive pricing, precise quality control, and fast delivery globally.

Q3: Can CNC Milling handle prototypes and large-volume orders?

A3: Yes. CNC Milling is ideal for both single-piece prototypes and full-scale production due to its repeatability and digital control.

Q4: What’s the difference between CNC Milled parts and CNC Turned parts?

A4: CNC Milled parts are typically shaped using rotating cutting tools on a fixed workpiece, while CNC Turned parts are shaped by rotating the workpiece against fixed tools.