Lavorazione CNC has revolutionized modern manufacturing, and among its most powerful innovations is Lavorazione CNC a 5 assi. È diventato indispensabile per le aziende di tutti i settori come automobilistico, costruzione di macchine e automazione, thanks to its superior accuracy, efficiency, and design flexibility. In this article, we dive deep into what makes 5-axis CNC machining such a transformative force in high-precision metal parts production, especially for clients seeking reliable partners like CNCRUSH, una fabbrica di lavorazione CNC con sede in Cina con oltre 12 anni di esperienza nel settore Parti fresate CNC E Pezzi torniti CNC.

Summary of Source Content

The reference sources collectively highlight these key points:

-

5-axis CNC machining offers enhanced precision, faster cycle times, and complex part geometry.

-

Industries like aerospace, automotive, and medical rely on this technology.

-

Simultaneous 5-axis machining enables tool movement in five directions, reducing setup time.

-

Modern 5-axis CNC machines are compact, smart, and adaptive.

-

Services from global manufacturers emphasize quick turnaround, accuracy, and flexibility.

-

China-based suppliers are becoming global leaders in providing affordable yet reliable 5-axis CNC machining.

Building on these themes, we now explore the topic with deeper analysis.

1. CNC Machining and the Rise of 5-Axis Technology

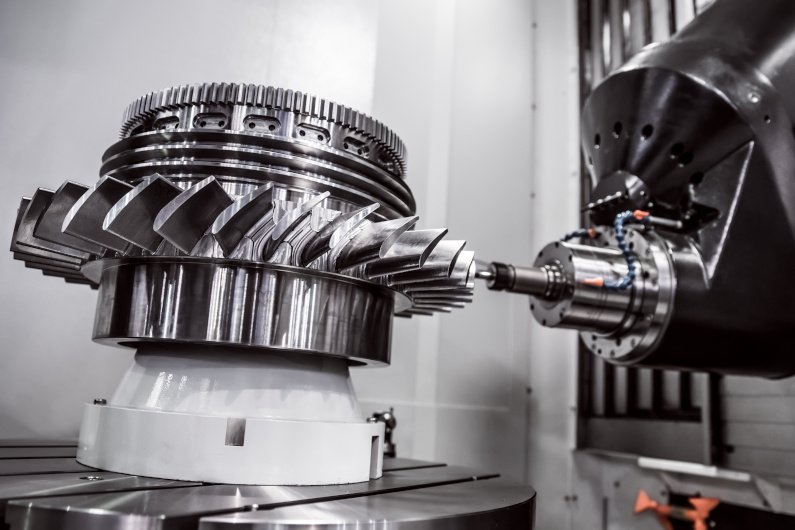

Lavorazione CNC has evolved dramatically from traditional 3-axis milling to sophisticated Lavorazione a 5 assi that enables five-sided access to workpieces. This advancement allows for shorter lead times, less material waste, and reduced human error. È una svolta positiva per i produttori che richiedono velocità e perfezione nella produzione Parti fresate CNC E Pezzi torniti CNC.

Perché è importante

For industries that rely on ultra-precise components, such as automobilistico, even the smallest misalignment can cause catastrophic results. Lavorazione CNC a 5 assi ensures higher consistency, which is crucial for both prototyping and mass production.

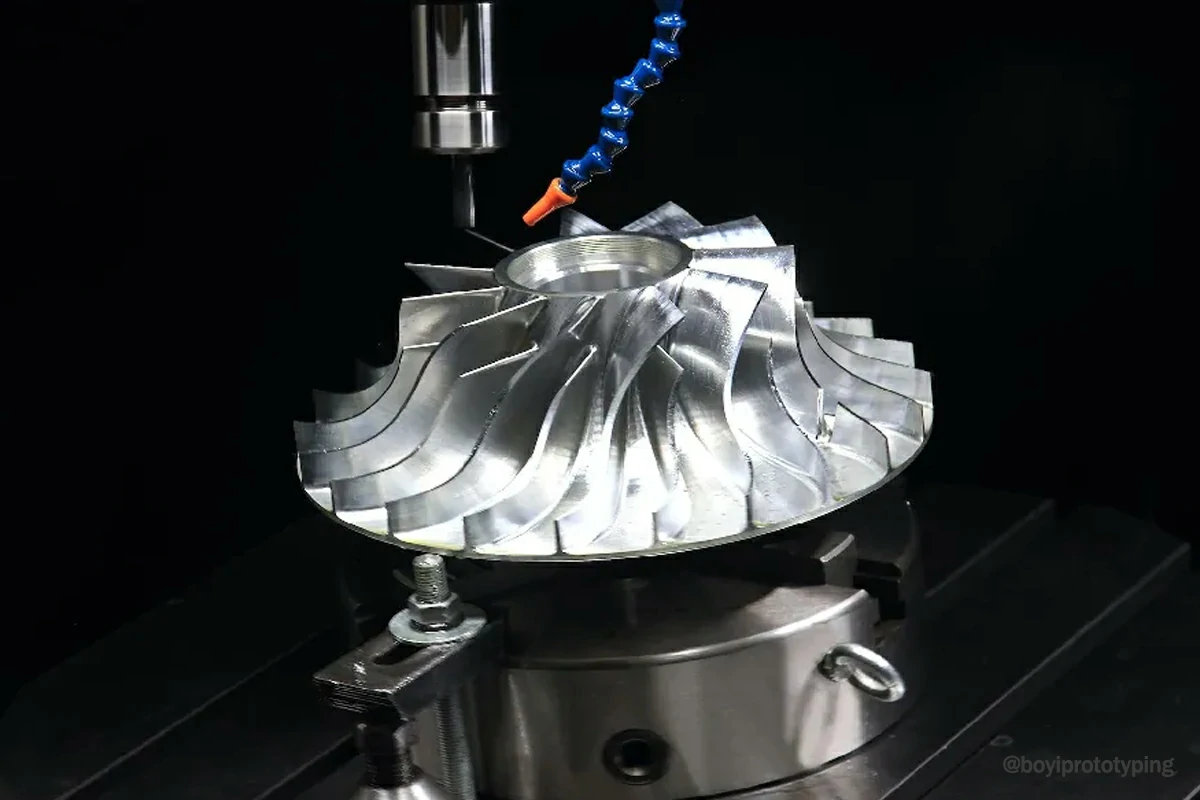

2. The Core Mechanics of 5-Axis CNC Machining

Unlike 3-axis machines that move in X, Y, and Z directions, Macchine CNC a 5 assi also rotate on the A and B axes. This additional range of motion allows the tool to approach the part from virtually any angle without the need for repositioning.

| Axis | Movement Direction | Descrizione |

|---|---|---|

| X | Left to Right | Horizontal movement |

| Y | Front to Back | Depth movement |

| Z | Up and Down | Vertical movement |

| UN | Rotates around X | Tilt function |

| B | Rotates around Y | Swivel or spin for angular precision |

This multi-directional movement enhances surface finish and enables the production of highly complex Parti fresate CNC in a single setup.

3. CNC Machining Service Providers Are Going Global

The demand for Servizi di lavorazione CNC is increasing worldwide, and China is emerging as a powerhouse in this domain. A CNCRUSH, we’ve been delivering top-tier Parti fresate CNC E Pezzi torniti CNC for over a decade, catering to industries that require both precision and speed.

With advanced 5-axis machinery and a professional QC team, CNCRUSH ensures defect-free results and fast lead times — all while keeping costs under control.

4. Advantages of 5-Axis CNC Machining for Metal Parts

Positive sentiment around 5-axis CNC machining is justified due to the numerous benefits it brings:

-

Meno configurazioni: Complex geometries can be machined in one go.

-

Tolleranze più strette: Perfect for aerospace and automobilistico componenti.

-

Migliore finitura superficiale: Ideal for both functional and aesthetic parts.

-

Maggiore durata dell'utensile: Optimized angles reduce tool wear.

| Beneficio | Impact on CNC Machining Service |

|---|---|

| Meno configurazioni | Faster turnaround, less human error |

| Tolleranze più strette | Improves reliability in critical industries |

| Smoother surface | Reduces post-processing needs |

| Improved tool usage | Lowers cost per unit |

5. CNC Machining for the Automotive Industry

Servizi di lavorazione CNC are essential to modern automobilistico manufacturing. From gearboxes to suspension parts, 5-axis machining enables precise, reliable production of critical components. At CNCRUSH, our experience serving automotive clients gives us a deep understanding of industry demands.

Our team specializes in high-strength Pezzi torniti CNC and complex Parti fresate CNC for drivetrain and chassis components.

6. CNC Milled Parts for Machine Building & Automation

High-performance machinery and automation equipment require parts with exact tolerances and robust materials. CNCRUSH delivers Parti fresate CNC for machine frames, actuators, and custom fixtures used in robotics and factory automation systems.

Whether you need a prototype or full-scale production, our Servizi di lavorazione CNC can scale to meet your volume and complexity.

7. Cost-Effective 5-Axis CNC Machining Without Quality Loss

One common myth is that 5-axis machining is prohibitively expensive. While initial machine costs are higher, the long-term ROI is impressive:

-

Reduced scrap

-

Fewer labor hours

-

Lower assembly errors

CNCRUSH leverages efficient workflows and smart toolpath programming to deliver Servizi di lavorazione CNC at competitive rates — without compromising quality.

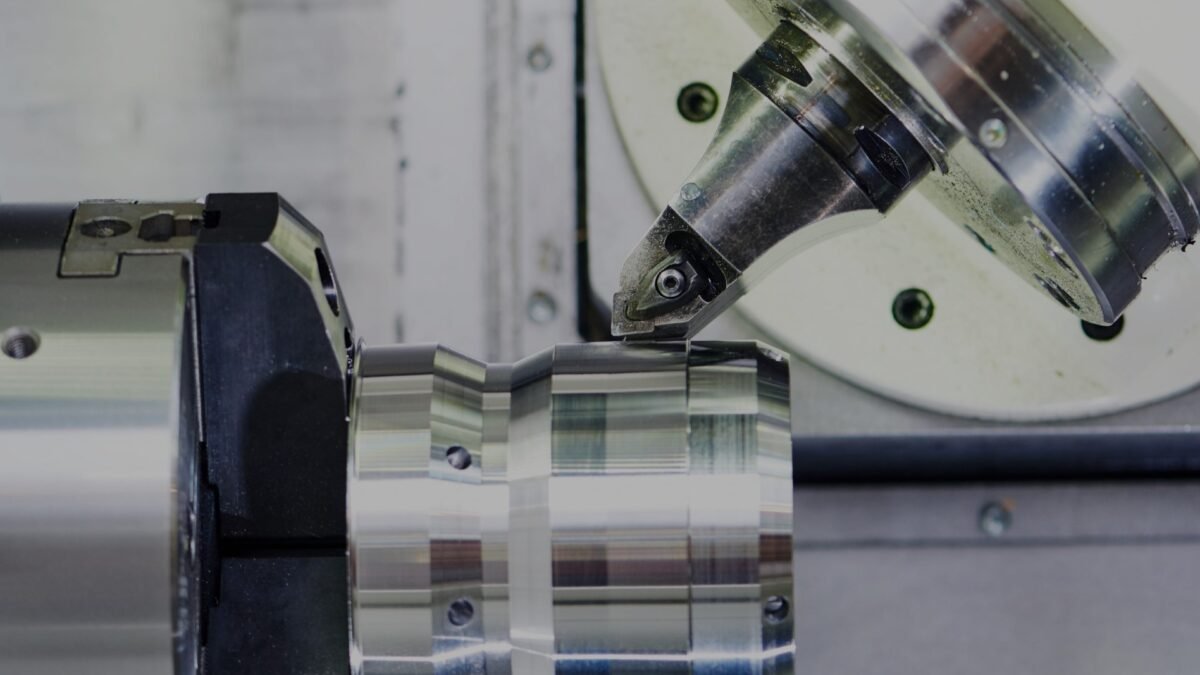

8. How CNCRUSH Ensures Quality in CNC Turned Parts

For components like shafts, bushings, and custom fasteners, precision turning is non-negotiable. Nostro Pezzi torniti CNC go through stringent inspections using CMMs, height gauges, and micrometers.

With over 12 years of experience, CNCRUSH has developed a quality system that exceeds client expectations — a key reason we’re trusted by companies in Europe, North America, and Australia.

9. Choosing the Right CNC Machining Service Provider

When choosing a CNC supplier, consider these key factors:

-

Experience and specialization (like 5-axis machining)

-

Quality assurance processes

-

Communication and support

-

Scalability and turnaround time

CNCRUSH checks all these boxes. We’re proud of our long-term partnerships and track record of handling complex projects in automobilistico, costruzione di macchine e automazione settori.

10. The Future of 5-Axis CNC Machining

The future is intelligent, automated, and global. As software becomes smarter and machines more adaptive, 5-axis CNC machining will play an even greater role in shaping the next generation of products.

At CNCRUSH, we continuously invest in the latest equipment and training to stay at the forefront of Servizio di lavorazione CNC excellence. We welcome clients looking for both innovation and reliability.

Domande frequenti (FAQ)

Q1: What materials can you machine with 5-axis CNC?

We handle aluminum, steel, titanium, plastics, and more.

Q2: How precise is your 5-axis machining?

We achieve tolerances as tight as ±0.005mm depending on the part.

Q3: Can you help with prototyping and full-scale production?

Yes, CNCRUSH supports everything from rapid prototyping to high-volume production runs.

Q4: Do you provide finishing services?

Yes, including anodizing, powder coating, polishing, and more.

Q5: Where is CNCRUSH located?

We are based in China and have been offering Servizi di lavorazione CNC globally for 12+ years.

Conclusione:

Se stai cercando servizi di alta qualità, convenienti e con esperienza Servizi di lavorazione CNC per il tuo Parti fresate CNC O Pezzi torniti CNC, especially with advanced 5-axis capabilities, look no further than CNCRUSH. Our dedication to precision, innovation, and customer satisfaction makes us the ideal partner for your manufacturing needs.