5-Axis CNC Machining is revolutionizing the manufacturing process for complex metal parts across industries. Whether you’re producing parts for automotive, aerospace, or machine building, this advanced technology is essential for creating high-precision, complex designs. At CNCRUSH, with over 12 years of experience in CNC machining services, we specialize in providing top-quality CNC milled parts and CNC turned parts for global clients. In this article, we’ll explore the reasons why 5-Axis CNC machining is vital for precision manufacturing, focusing on how it impacts industries like automotive and automation. We’ll also explain how CNCRUSH’s expertise can be the perfect solution for your needs.

What is 5-Axis CNC Machining?

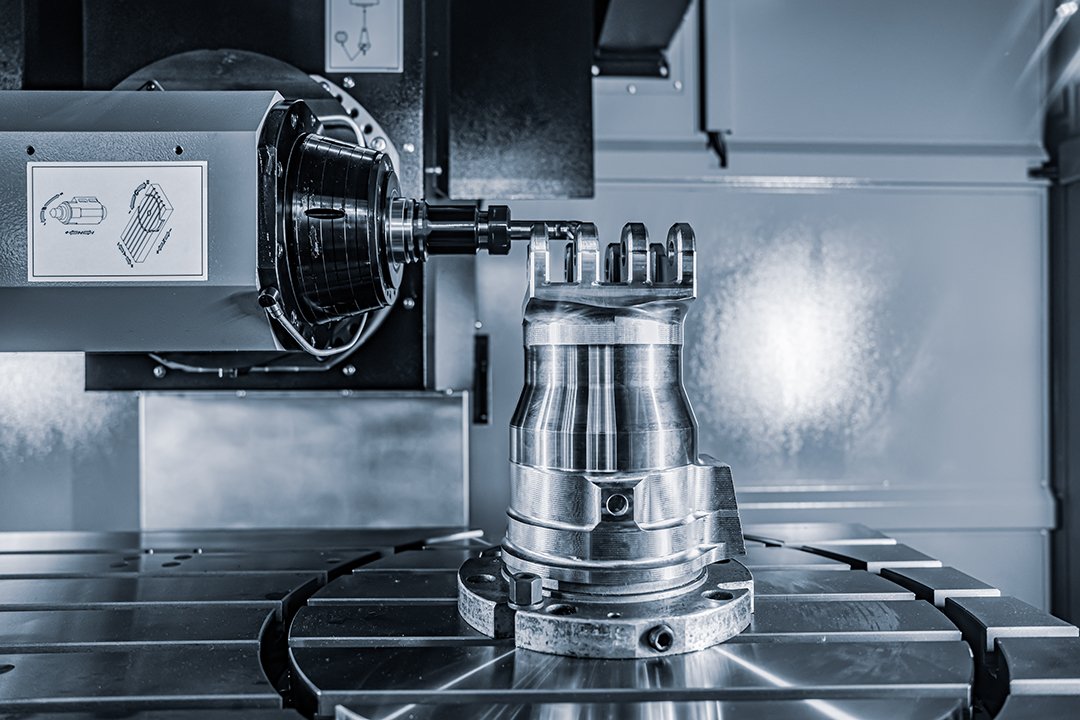

5-axis CNC machining is an advanced manufacturing process that allows a CNC machine to move a part or tool across five different axes simultaneously. This is far superior to the traditional 3-axis CNC, which only moves in three directions. The five axes in this process typically consist of three linear axes (X, Y, and Z), which control the movement of the tool, and two rotational axes (A and B), which allow the part to be rotated along different planes for complex cuts.

The primary advantage of 5-axis CNC machining is its ability to produce parts that would be impossible or highly time-consuming with 3-axis machines. In industries like automotive and aerospace, parts often require intricate geometries that can only be achieved with the advanced capabilities of 5-axis machining. This precision and flexibility reduce the need for multiple setups, making it ideal for high-quality and high-volume production.

Why is 5-Axis CNC Machining Ideal for Complex Parts?

The intricacies of modern designs often require multi-dimensional machining to achieve the precision and accuracy needed. 5-axis CNC machining eliminates the limitations of traditional methods by providing superior flexibility. In a single setup, it can work on all sides of a part, cutting, drilling, and shaping complex geometries that would otherwise require multiple machines or setups.

For example, automotive components such as engine parts, chassis components, and even suspension systems require exact precision for proper function. The ability to handle parts that are intricate in both shape and design is a key benefit. Additionally, 5-axis machining enhances the quality of parts by improving surface finishes and achieving higher tolerances in critical dimensions.

Key Benefits of 5-Axis CNC Machining for Manufacturers

5-axis CNC machining offers numerous advantages, particularly for manufacturers in sectors where precision is a must. Here are some of the key benefits:

-

Reduced Setup Time: Traditional CNC machines require multiple setups to machine complex parts. With 5-axis machining, a part can be fully machined in one setup, reducing both time and the risk of errors.

-

Improved Precision: By allowing the tool to work from multiple angles simultaneously, 5-axis machining provides superior precision, which is essential for complex parts like turbine blades or suspension systems.

-

Cost Efficiency: Although 5-axis machines are an investment, they lead to long-term cost savings by reducing setup time, the number of machines required, and material waste.

-

Flexibility: This process allows manufacturers to handle a wide variety of materials, including metals, plastics, and composites, making it suitable for industries such as aerospace, automotive, and medical device manufacturing.

The Role of 5-Axis CNC Machining in Automotive Manufacturing

The automotive industry often faces challenges related to part complexity, precision, and durability. Components such as engine blocks, transmission parts, and brake systems require a level of accuracy that is difficult to achieve with traditional machining methods. 5-axis CNC machining, with its ability to handle complex shapes and geometries, is a game-changer in automotive manufacturing.

For example, the production of lightweight components such as aluminum engine blocks or structural parts relies on the precision that 5-axis CNC machining provides. By using 5-axis machines, manufacturers can create intricate designs that reduce the weight of the parts without compromising on strength. This leads to more fuel-efficient vehicles and higher-performance components.

5-Axis CNC Machining for Aerospace and Machine Building

Aerospace and machine building are two of the industries that benefit most from the capabilities of 5-axis CNC machining. These sectors require parts that meet extremely high standards for strength, precision, and durability. Components like turbine blades, fuel nozzles, and intricate brackets used in aerospace applications demand the highest tolerances, which 5-axis CNC machining can achieve.

5-axis machining also plays a critical role in the production of highly complex parts in the machine-building industry. The process’s ability to handle heavy-duty materials such as titanium and high-strength alloys makes it ideal for producing robust components that can withstand extreme conditions.

What Materials are Best Suited for 5-Axis CNC Machining?

5-axis CNC machining is highly versatile and can handle a wide range of materials. Some of the best materials suited for this advanced process include:

-

Aluminum: Lightweight and versatile, aluminum is frequently used in automotive and aerospace industries for structural components.

-

Steel: High-strength steel is often used for machine parts that require superior strength and durability, such as gears, shafts, and brackets.

-

Titanium: Known for its strength-to-weight ratio, titanium is used in aerospace for parts like turbine blades and in medical applications for implants.

-

Plastics and Composites: Certain high-performance plastics and composite materials are also machined using 5-axis CNC, especially for parts that require complex shapes and lightweight properties.

How Does 5-Axis CNC Machining Improve Part Quality and Speed?

One of the major advantages of 5-axis CNC machining is its ability to produce high-quality parts in a shorter amount of time. Because it eliminates the need for multiple machine setups, it reduces the potential for errors that can arise when transitioning between machines. Furthermore, by machining parts from multiple angles in one go, it achieves better surface finishes, reducing the need for post-processing.

For industries like automotive or aerospace, where performance and reliability are critical, the speed and accuracy of 5-axis CNC machining are paramount. This process improves not just the physical quality of the parts but also the efficiency of production schedules, which is especially important for time-sensitive manufacturing cycles.

5-Axis CNC Machining and Cost Efficiency

While the initial investment in 5-axis CNC machinery may be higher than traditional machines, the long-term cost benefits make it a worthwhile investment. With fewer setups required, manufacturers save on labor and machine downtime. Additionally, the improved precision reduces material waste, which is a significant cost-saving factor, especially in industries dealing with expensive raw materials like titanium or carbon fiber.

For companies in sectors like automotive, machine building, and aerospace, 5-axis CNC machining offers both quality and efficiency, ensuring that they remain competitive while also optimizing production costs.

Why CNCRUSH is Your Go-To for 5-Axis CNC Machining Services

At CNCRUSH, we have over 12 years of experience in providing high-precision CNC machining services, specializing in both CNC milled parts and CNC turned parts. Our state-of-the-art equipment and expertise in 5-axis CNC machining ensure that we can meet the most complex design requirements for our clients across various industries, including automotive, machine building, and automation.

We understand the demands of global clients and are committed to providing solutions that optimize cost, quality, and delivery timelines. Our team is dedicated to offering customized CNC machining services that meet your exact specifications while maintaining the highest standards of precision and quality.

The Future of 5-Axis CNC Machining and Its Impact on Industries

Looking ahead, 5-axis CNC machining is expected to evolve even further with the integration of new technologies. Automation, AI, and machine learning are beginning to play a role in improving the precision and efficiency of these machines. As these technologies continue to develop, we expect even more cost-effective and faster production processes.

In industries like aerospace and automotive, the demand for even more intricate designs and higher precision will only increase. 5-axis CNC machining will continue to be an essential tool for achieving these goals, enabling manufacturers to create parts that were once considered too complex or costly to produce.

Table 1: Comparison of 3-Axis vs. 5-Axis CNC Machining

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Flexibility | Limited | Highly Flexible |

| Setup Time | Longer | Shorter |

| Accuracy | Lower | Higher |

| Surface Finish | Average | Superior |

| Complexity Handling | Low | High |

Table 2: Common Materials for 5-Axis CNC Machining

| Material | Applications | Strength & Durability |

|---|---|---|

| Aluminum | Automotive, Aerospace | Lightweight & Strong |

| Titanium | Aerospace, Medical | Extremely Durable |

| Steel | Industrial Machinery | High Strength |

FAQ Section

Q1: How does 5-axis CNC machining save time during production?

By reducing the need for multiple setups and providing simultaneous movement along multiple axes, 5-axis CNC machining cuts down production time significantly.

Q2: Is 5-axis CNC machining suitable for small batch production?

Yes, it is highly efficient for both small and large batch production, providing the flexibility and precision needed for complex parts in lower volumes.

Conclusion

In conclusion, 5-axis CNC machining is a critical technology for manufacturers that require high-precision, complex metal parts. Industries like automotive, aerospace, and machine building have much to gain from its capabilities, as it improves quality, reduces production time, and enhances cost efficiency. Whether you’re in the automotive industry, aerospace, or machine building, 5-axis CNC machining can significantly enhance your production capabilities, and CNCRUSH is here to help you take advantage of this cutting-edge technology.