5-Axis CNC Machining has revolutionized the manufacturing of medical devices, offering unprecedented precision, efficiency, and flexibility. In a field where accuracy and biocompatibility are critical, this advanced machining technology has become a cornerstone for creating life-saving equipment. Whether it’s surgical instruments, implants, or diagnostic devices, 5-Axis CNC Machining enables manufacturers to meet stringent industry standards while improving production timelines.

At CNCRUSH, a leading CNC machining services provider with over 12 years of experience, we specialize in producing CNC Milled parts and CNC Turned parts tailored to medical, automotive, and automation industries. Located in China, our factory combines cutting-edge 5-axis machining capabilities with exceptional service to deliver high-quality parts trusted worldwide.

What Makes 5-Axis CNC Machining Essential in Medical Manufacturing?

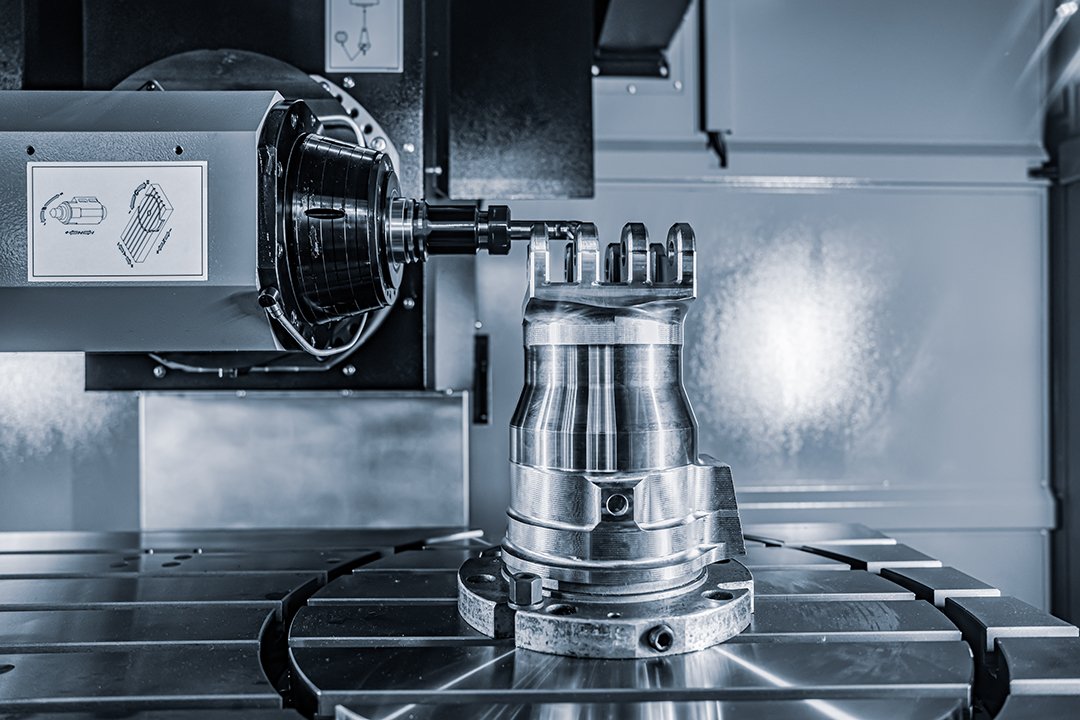

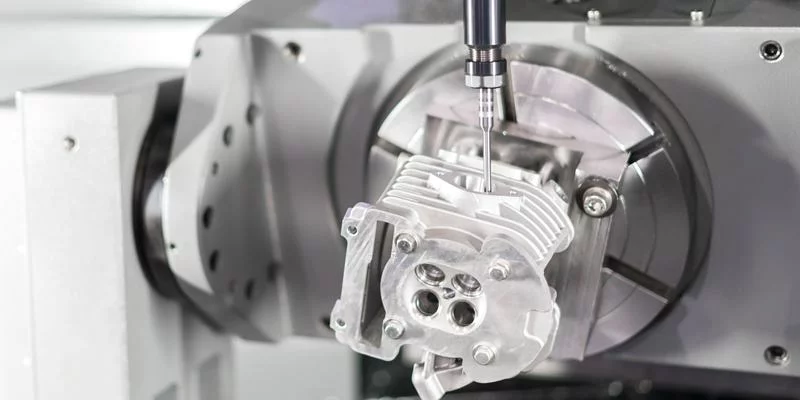

The importance of 5-axis CNC machining lies in its ability to machine complex geometries with a single setup. Unlike traditional 3-axis systems, it allows simultaneous movement along five axes, enabling precise cuts and contours on intricate designs. This efficiency is especially critical in medical applications, where parts often feature delicate, multi-dimensional surfaces.

Let’s explore the transformative impact of this technology through ten critical aspects:

1. Enhancing Precision with 5-Axis CNC Machining

In medical manufacturing, precision is non-negotiable. Whether crafting a prosthetic implant or a surgical guide, even the slightest deviation can compromise patient safety.

Key Benefits:

- Reduced Errors: 5-axis machining minimizes human intervention by completing complex cuts in a single operation.

- Perfect Alignment: Simultaneous multi-axis movement ensures flawless angles and smooth transitions between surfaces.

- Tight Tolerances: This technology consistently achieves tolerances as low as ±0.001 mm, vital for implants like hip joints and bone plates.

At CNCRUSH, we’ve delivered countless CNC Milled parts for medical devices, ensuring unparalleled precision that adheres to ISO standards.

2. Accelerating Production with Fewer Setups

Time is critical when manufacturing medical devices, especially during emergencies or pandemics. With 5-axis CNC machining, parts requiring multiple setups on 3-axis machines can be completed in a single pass.

How It Helps:

- Faster Turnaround: Streamlined production minimizes downtime.

- Improved Workflow: Reduced handling decreases the chance of errors during transitions.

- Scalable Output: High efficiency supports both prototyping and mass production.

💡 Example: Our factory in China leveraged 5-axis machining to cut production time for a complex surgical instrument by 30%, helping a client meet urgent demand.

3. Simplifying Complex Geometries

Medical devices often feature intricate designs that traditional machining cannot handle efficiently. 5-Axis CNC Machining excels at manufacturing parts with curved surfaces, undercuts, and intricate internal cavities.

Applications Include:

- Implants: Customized spinal implants with complex shapes.

- Surgical Tools: Minimally invasive instruments requiring precise contours.

- Diagnostic Equipment: Components with intricate channels for fluid or airflow management.

At CNCRUSH, our expertise in producing custom parts ensures your designs are brought to life with the highest level of accuracy.

4. Reducing Material Waste

In medical manufacturing, materials like titanium, stainless steel, and PEEK are expensive. 5-axis machining optimizes cutting paths to reduce waste while maintaining structural integrity.

Cost Savings:

- Minimal Scrap: Precise cutting avoids excess material removal.

- Efficient Nesting: Multiple parts can be machined from a single block with optimized layouts.

💡 Did You Know? CNCRUSH’s affordable CNC machining solutions save clients up to 20% on material costs by leveraging 5-axis efficiency.

5. Improving Surface Finishes for Biocompatibility

Surface finish is crucial in medical devices to ensure biocompatibility and prevent infection. 5-axis machining delivers superior finishes without secondary operations.

| Finish Type | Importance in Medical Devices | Applications |

|---|---|---|

| Mirror Finish | Reduces friction and improves biocompatibility. | Orthopedic implants. |

| Smooth Surface | Enhances sterilization and durability. | Surgical tools. |

6. Unlocking Advanced Material Compatibility

5-axis CNC machines handle biocompatible materials with ease. These include metals, plastics, and composites used in medical applications.

| Material | Properties | Common Use Cases |

|---|---|---|

| Titanium | High strength, lightweight, biocompatible. | Orthopedic and dental implants. |

| PEEK | High thermal resistance, non-reactive. | Spinal cages, prosthetic devices. |

| Stainless Steel | Corrosion resistance, sterilization-ready. | Surgical tools. |

7. Meeting Stringent Regulatory Standards

Medical device manufacturing is subject to rigorous standards like ISO 13485 and FDA requirements. 5-axis CNC machining ensures compliance by delivering consistent, traceable results.

Features That Enable Compliance:

- Repeatability: Ensures identical production of parts in high volumes.

- Process Validation: Enables detailed monitoring of every production step.

At CNCRUSH, our experience in precision CNC machining ensures every medical device part meets global regulatory requirements.

8. Facilitating Rapid Prototyping for Innovation

The medical industry thrives on innovation. 5-axis CNC machining supports rapid prototyping, enabling manufacturers to test and refine designs before mass production.

Advantages for Prototyping:

- Speed: Quickly produce functional prototypes for testing.

- Flexibility: Easily switch between materials or designs.

9. Enhancing Automation and Scalability

Modern 5-axis CNC machines integrate seamlessly with automation systems, enabling lights-out manufacturing. This is critical for scaling production to meet growing demand.

Key Features:

- Automated Tool Changes: Reduce manual intervention.

- Real-Time Monitoring: Detect and correct issues immediately.

10. Boosting Cost-Effectiveness

While the initial investment in 5-axis technology may seem high, the long-term savings are undeniable. By reducing labor, material waste, and production time, manufacturers can significantly lower costs.

💡 Case Study: A client in the medical automation industry reduced manufacturing costs by 25% using CNCRUSH’s custom CNC solutions.

FAQs: 5-Axis CNC Machining for Medical Devices

1. Why is 5-axis machining better than 3-axis for medical devices?

5-axis machining eliminates multiple setups, enabling faster, more precise production of complex geometries.

2. Can 5-axis machines handle biocompatible materials?

Yes, they are ideal for processing titanium, stainless steel, and advanced polymers like PEEK.

3. How does 5-axis machining improve surface finish?

It enables smooth transitions and precise tool control, reducing the need for secondary finishing.

Why Choose CNCRUSH for Medical CNC Machining?

With over 12 years of expertise in CNC machining services, CNCRUSH is a trusted partner for medical manufacturers worldwide. Our China CNC factory delivers high-quality CNC Milled parts and CNC Turned parts, tailored to your specific needs.

👉 Contact us today to learn how we can support your medical device manufacturing projects!