In the Auto Parts Manufacturing industry, efficiency and precision are critical for producing high-quality, reliable parts. CNC machining has revolutionized the way automotive components are manufactured, optimizing processes for faster production, improved quality, and reduced costs. By leveraging advanced CNC machining techniques, manufacturers can meet rigorous standards, achieving consistently high-quality results. This article explores the techniques used to enhance efficiency in automotive CNC machining and how it supports faster production without sacrificing accuracy. With over 12 years of experience, CNCRUSH specializes in CNC machining services for CNC Milled Parts and CNC Turned Parts, helping automotive clients and others achieve unparalleled quality and precision in their parts.

Table of Contents

- Introduction to CNC Machining in Automotive Manufacturing

- Benefits of CNC Machining Services for Automotive Parts

- Precision in CNC Milled Parts for Automotive Applications

- The Importance of CNC Turned Parts in Automotive Manufacturing

- Multi-Axis CNC Machining for Complex Automotive Parts

- Efficiency Gains through CNC Automation and Process Optimization

- Quality Control and Precision Measurement in CNC Machining

- Material Compatibility for CNC Machined Auto Parts

- Prototype to Production: Scaling with CNC Machining

- Why Choose a China-Based CNC Machining Factory for Automotive Components

1. Introduction to CNC Machining in Automotive Manufacturing

The automotive industry demands rapid, precise production for complex parts. CNC machining meets these demands by allowing the production of components with intricate geometries and tight tolerances, essential for the reliability of automotive systems. CNC machines can create complex forms that meet the industry’s high standards, ensuring parts are durable, accurate, and ready for high-performance applications.

2. Benefits of CNC Machining Services for Automotive Parts

CNC machining offers significant advantages in Auto Parts Manufacturing. By using CNC machining services, companies can benefit from rapid production cycles, improved repeatability, and cost-efficiency. For high-performance parts, CNC machining allows for detailed, precise designs that traditional methods can’t achieve. CNCRUSH, with its experience in CNC milling and turning, delivers consistent, high-quality results for automotive clients worldwide.

3. Precision in CNC Milled Parts for Automotive Applications

Automotive components often require CNC Milled Parts with precise flat surfaces, grooves, and slots, essential for everything from engine housings to braking system components. CNC milling allows for intricate part designs with high tolerance levels, maintaining consistency across all production runs. With 3-axis, 4-axis, and 5-axis capabilities, CNCRUSH can meet complex specifications, helping automotive manufacturers reduce errors and optimize performance.

Table 1: Key CNC Milled Auto Parts Manufacturing and Their Applications

| Part | Application Area | Benefits of CNC Milled Parts |

|---|---|---|

| Engine Components | Powertrain | High strength, precise alignment |

| Transmission Housings | Transmission Systems | Durability, complex geometry management |

| Brake System Frames | Safety Mechanisms | High tolerance, exacting dimensions |

4. The Importance of CNC Turned Parts in Automotive Manufacturing

CNC Turned Parts are widely used for cylindrical automotive components, such as shafts, bearings, and fasteners, where precise dimensions and smooth surface finishes are essential. CNC turning allows for tight tolerance control, making it ideal for producing high-precision parts that reduce friction and wear. CNCRUSH’s CNC turning services enable rapid and cost-effective production of these critical components for automotive applications.

5. Multi-Axis CNC Machining for Complex Automotive Parts

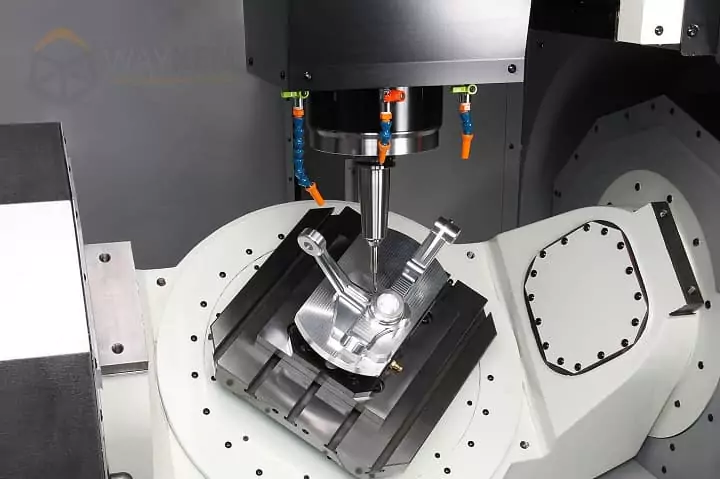

Multi-axis CNC Auto Parts Manufacturing, including 4-axis and 5-axis capabilities, enables the production of highly complex shapes required in automotive components, such as suspension systems, exhaust manifolds, and turbocharger housings. These advanced techniques reduce the need for multiple setups, enhancing accuracy and efficiency, which is vital for high-volume manufacturing in the automotive industry.

6. Efficiency Gains through CNC Automation and Process Optimization

Automation in CNC Auto Parts Manufacturing drives efficiency, particularly for high-volume automotive production. By using computer-controlled systems, CNC machines can execute complex processes without manual intervention, reducing human error and increasing throughput. The automation of CNC machining allows CNCRUSH to achieve faster production cycles for clients in the automotive, machine building, and automation industries, improving cost-effectiveness and meeting tight deadlines.

7. Quality Control and Precision Measurement in CNC Machining

High precision is crucial for the automotive industry, where part defects can impact safety and performance. CNC Auto Parts Manufacturing incorporates automated quality control processes like in-line measurement and inspection, ensuring each part meets exacting standards. Advanced techniques like coordinate measuring machines (CMM) help ensure components are accurately measured and defect-free.

8. Material Compatibility for CNC Machined Auto Parts

Automotive parts require materials that can withstand high stresses and environmental challenges. CNC machining supports a range of metals like aluminum, steel, brass, and plastics, each suited to different automotive components. CNCRUSH’s material expertise allows it to deliver CNC machined parts with optimal strength, corrosion resistance, and durability, meeting industry-specific needs.

Table 2: Materials Commonly Used in Auto Parts Manufacturing

| Material | Characteristics | Typical Automotive Application |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Engine blocks, transmission housings |

| Steel | High strength, heat resistance | Structural components, gears |

| Brass | Corrosion resistance, machinability | Fittings, bearings |

| Plastics | Lightweight, moldable | Dashboard parts, interior fittings |

9. Prototype to Production: Scaling with Auto Parts Manufacturing

One of CNC machining’s strengths is its adaptability from prototyping to full-scale production. This flexibility allows automotive companies to test part designs in the early stages and quickly move to mass production without compromising quality. At CNCRUSH, prototyping allows clients to fine-tune part designs, ensuring that the final production run meets both performance and quality expectations.

10. Why Choose a China-Based CNC Machining Factory for Automotive Components

Partnering with a Auto Parts Manufacturing factory in China, such as CNCRUSH, offers automotive companies access to high-quality manufacturing at competitive costs. With over 12 years in the industry, CNCRUSH provides a trusted CNC machining service with experience in CNC Milled Parts and CNC Turned Parts. Our commitment to global standards and advanced CNC capabilities ensures automotive components are manufactured efficiently and to the highest quality.

FAQs about CNC Machining in Automotive Parts Manufacturing

Q1: How does CNC machining benefit automotive manufacturing?

CNC machining offers high precision, scalability, and the ability to produce complex geometries essential for automotive components.

Q2: Which materials are commonly used in CNC automotive parts?

Materials like aluminum, steel, brass, and plastics are used for their durability, weight, and strength, depending on the part requirements.

Q3: Why should automotive companies consider a CNC machining partner in China?

China-based CNC partners like CNCRUSH offer quality manufacturing, cost advantages, and adherence to global standards, providing reliable parts for international clients.

In conclusion, CNC machining has significantly enhanced Auto Parts Manufacturing, streamlining processes and ensuring the high-quality production of critical components. With extensive experience and a commitment to precision, CNCRUSH is well-positioned to support Auto Parts Manufacturing in achieving efficient, reliable production runs. Specializing in CNC Milled Parts and CNC Turned Parts, CNCRUSH delivers the precision and quality that automotive clients require, making us a trusted partner for global manufacturing needs.