Automotive parts manufacturing has experienced a revolution with CNC machining at its core. This advanced technology has transformed traditional manufacturing, enabling rapid prototyping, high-precision parts, and streamlined production processes.

CNC machining in the automotive industry also plays a crucial role in driving sustainability. By allowing manufacturers to achieve lightweight designs without compromising strength, CNC machining contributes to fuel efficiency and reduced emissions. This is especially valuable as automakers work to meet stringent environmental regulations and cater to the growing demand for eco-friendly vehicles.

1. Why CNC Machining is Essential in Automotive Manufacturing

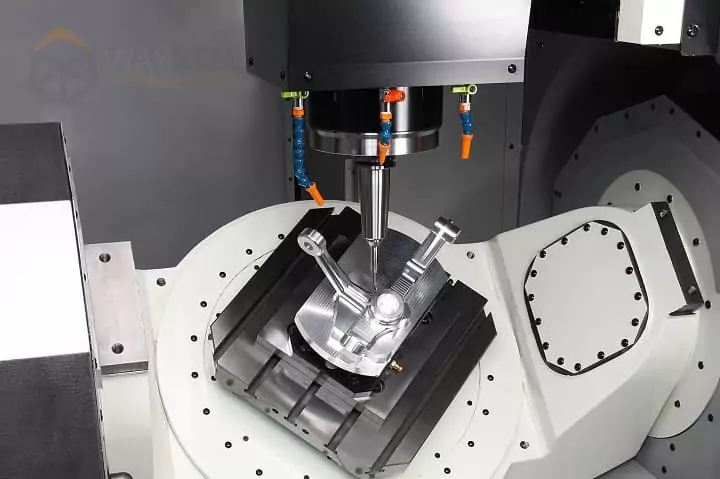

CNC machining stands at the forefront of modern automotive manufacturing due to its unparalleled ability to deliver high-precision components quickly and efficiently. Traditional manufacturing methods often struggle to meet the exacting standards required in the automotive industry, where even minute discrepancies can lead to safety issues or mechanical failures. CNC machines utilize computer-aided design (CAD) to achieve intricate designs and complex geometries that are critical for high-performance vehicles. This technology not only streamlines production processes but also enhances the overall quality and reliability of automotive parts.

2. Key Benefits of CNC Machining for Automotive Parts

- Precision: Essential for parts that require tight tolerances.

- Scalability: Supports production scalability without sacrificing quality.

- Efficiency: Reduces material waste and production time.

3. Applications of CNC Milled Parts and CNC Turned Parts in the Automotive Industry

CNC milled parts are utilized in a variety of critical automotive applications, including engine blocks, transmission housings, and intricate interior components. These parts benefit from the exceptional dimensional accuracy and surface finish that CNC milling provides. On the other hand, CNC turned parts, such as axles, gears, and fittings, are essential for ensuring smooth operation and safety in vehicles. By leveraging the capabilities of CNC machining, Automotive Parts Manufacturing can create parts that not only meet rigorous performance standards but also enhance the overall aesthetic appeal of the vehicles.

4. CNC Machining and Automation: A Growing Partnership

The integration of automation with CNC machining is reshaping the automotive manufacturing landscape. Automated systems can perform repetitive tasks such as loading and unloading materials, which not only increases productivity but also minimizes the risk of human error. This collaboration between humans and machines results in more consistent output quality and faster production cycles. Advanced robotics can also be employed for assembly processes, reducing the time to market and allowing manufacturers to respond more rapidly to changing consumer demands while maintaining strict quality control.

| Aspect | Traditional Manufacturing | CNC Machining + Automation |

|---|---|---|

| Precision | Lower | Higher |

| Cycle Time | Slower | Faster |

| Flexibility | Limited | High |

5. Materials in Automotive Parts Manufacturing: Aluminum, Steel, and Beyond

In automotive CNC machining, material selection is critical for achieving the desired performance characteristics. Aluminum is favored for its lightweight and corrosion-resistant properties, making it ideal for components where reducing weight is a priority. Steel, known for its strength and durability, is commonly used in structural components that require high tensile strength. Additionally, newer materials such as composites and advanced alloys are gaining traction, providing even greater performance benefits. Understanding the properties of these materials allows manufacturers to optimize their processes and deliver superior products.

6. Challenges in Automotive Parts Manufacturing

- Material Hardness: Dealing with harder materials poses a challenge.

- Maintaining Consistency: Ensuring uniform quality across high-volume production.

- Complex Geometries: CNC machining allows complex designs but requires precision.

7. The Role of CNC Machining in Lightweighting Initiatives

As the automotive industry pushes towards greater fuel efficiency and reduced emissions, lightweighting initiatives have become paramount. CNC machining plays a vital role in these efforts by enabling the production of lightweight yet robust components that can significantly lower a vehicle’s overall weight. By utilizing advanced CNC machining techniques, manufacturers can create parts with optimized geometries that reduce material usage while maintaining strength and performance. This not only contributes to sustainability goals but also improves vehicle handling and efficiency in Automotive Parts Manufacturing.

8. Quality Assurance in CNC for Automotive Parts Manufacturing

Ensuring the highest quality in automotive parts manufacturing is non-negotiable. CNC machining employs rigorous quality assurance protocols, including in-process inspections and final quality checks using advanced measurement technologies such as coordinate measuring machines (CMM). These measures ensure that every component meets the precise specifications required for safe and effective performance. Quality assurance is not just about compliance; it is also about building trust with clients and consumers who rely on the integrity of automotive parts for their safety.

| Quality Metric | Standard Requirement | CNC Machining Compliance |

|---|---|---|

| Tolerance | ±0.01 mm | Yes |

| Surface Finish | 32 µin Ra | Yes |

9. CNC Machining and Electric Vehicles (EVs)

As the shift towards electric vehicles gains momentum, CNC machining is becoming increasingly important in this emerging market. The unique design requirements of EVs, including battery enclosures and lightweight structural components, necessitate advanced machining capabilities. CNC machining enables manufacturers to produce these complex parts with high precision and repeatability, which is crucial for maximizing efficiency and performance. As the automotive landscape evolves, CNC machining will continue to play a vital role in supporting the growth of sustainable transportation solutions.

10. The Future of CNC Machining in Automotive Parts Manufacturing

Looking ahead, the future of CNC machining in automotive manufacturing promises exciting advancements. The integration of artificial intelligence (AI) and machine learning into CNC systems will enable smarter, more adaptive manufacturing processes that optimize production efficiency and reduce downtime. Predictive maintenance technologies will allow manufacturers to foresee equipment issues before they arise, minimizing disruptions and enhancing productivity. As these innovations unfold, CNC machining will solidify its position as an indispensable tool in the automotive industry, driving both performance and sustainability.

FAQ Section

- Why is CNC machining preferred in automotive parts manufacturing?

CNC machining offers the precision and scalability required for high-demand automotive parts production. - What materials are used in CNC automotive parts manufacturing?

Aluminum, steel, brass, and various plastics are commonly used, each selected based on strength, weight, and durability needs.

CNC machining is revolutionizing automotive parts manufacturing through its unmatched precision, efficiency, and ability to support complex designs. As the industry continues to evolve, manufacturers like CNCRUSH, with over 12 years of experience in providing high-quality CNC Milled and CNC Turned parts, are well-positioned to meet the demands of this dynamic market. Explore more about our specialized CNC machining services at CNCRUSH.

For more detailed information and services, explore CNCRUSH’s website.