Introduction

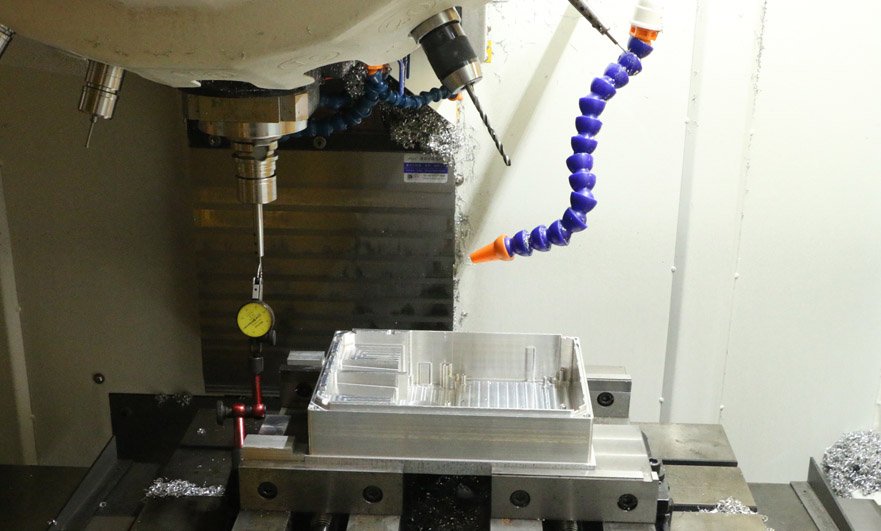

CNC machining, also known as Computer Numerical Control machining, has revolutionized the manufacturing of medical equipment, delivering unprecedented precision, adaptability, and efficiency. This technology allows for the rapid production of critical parts used in medical devices, surgical instruments, implants, and prosthetics, supporting the evolving demands of modern healthcare. This article explores the key benefits of CNC machining in the medical industry and explains why medical manufacturers increasingly turn to this advanced manufacturing technique.

At CNCRUSH, a China-based CNC machining factory with over 12 years of experience, we specialize in CNC Milled parts and CNC Turned parts, providing exceptional quality to our global clients. Our expertise in medical CNC machining makes us a trusted partner for companies seeking precision and reliability in medical parts production.

Benefits of CNC Machining for Medical Equipment

1. Unmatched Precision and Consistency in Part Production

Precision is critical in the medical sector, where equipment and devices must adhere to strict tolerances for safety and functionality. CNC machining achieves tolerances within microns, ensuring that parts are produced consistently across production runs. This precision is particularly beneficial in the manufacturing of surgical instruments, orthopedic implants, and diagnostic devices, where even minor variations can impact patient outcomes. At CNCRUSH, our precision-oriented approach supports high-quality medical parts for complex applications.

2. Efficient Prototyping and Iterative Testing

One of the main advantages of CNC machining in the medical industry is its ability to support rapid prototyping. By converting digital designs into physical prototypes swiftly, CNC machining allows engineers to test, refine, and finalize designs in a shorter period. For instance, when developing a new implant or surgical tool, CNC machining can help produce prototypes that enable testing for form, fit, and functionality before mass production.

3. Enhanced Customization for Patient-Specific Solutions

The medical industry increasingly seeks customized solutions, such as patient-specific implants and prosthetics tailored to an individual’s anatomy. CNC machining allows medical manufacturers to create parts that match precise specifications, enhancing patient comfort and treatment outcomes. Customization has proven especially valuable in fields like orthopedics and dental implants, where personalized parts can significantly improve recovery and integration with the body.

4. Flexibility in Material Choice

CNC machining supports an extensive range of materials suitable for medical applications. Metals like titanium and stainless steel are widely used for their biocompatibility and strength, making them ideal for implants and surgical tools. CNC machining also enables the use of high-performance plastics such as PEEK, which are commonly used for prosthetics and non-implantable medical devices. This flexibility allows CNCRUSH to provide clients with material options that meet the regulatory standards and performance needs of their products.

| Material | Application |

|---|---|

| Titanium | Implants, surgical instruments |

| Stainless Steel | Diagnostic devices, orthopedic screws |

| PEEK (Polyetheretherketone) | Prosthetics, endoscopic tools |

| Polycarbonate | Housings for medical equipment |

5. Reduction of Human Error through Automation

The automated nature of CNC manufacturing reduces the risk of human error, which is critical in the medical field. Computer-controlled processes ensure consistent quality in every piece, providing confidence in device safety and functionality. This level of reliability is crucial when producing components that will be used in life-saving or diagnostic devices, where the smallest defect could have significant implications.

6. Cost-Effectiveness and Material Efficiency

CNC manufacturing minimizes material waste through precise cutting and shaping, which is particularly important when working with expensive medical-grade materials. With less waste and reduced need for rework, CNC machining is an economical choice for medical manufacturing. At CNCRUSH, we optimize each production run to achieve cost-effective results without sacrificing quality, benefiting clients across industries, including automotive, machine building, and automation.

7. Accelerated Production Times for Market Demands

In the medical industry, quick response times are essential, especially when new products are urgently required. CNC manufacturing enables faster production cycles, allowing medical device companies to bring their products to market swiftly. CNCRUSH supports high-speed manufacturing for various medical applications, ensuring our clients remain competitive and responsive to market demands.

8. Compatibility with CAD/CAM Software for Streamlined Production

The integration of CNC manufacturing with CAD/CAM software allows for seamless design-to-manufacturing workflows, reducing lead times and enabling complex part geometries. By converting digital models directly into machine commands, this compatibility ensures accuracy from the design stage through to final production. CNCRUSH’s advanced CNC capabilities, including 5-axis machining, support intricate designs essential for sophisticated medical devices like robotic surgery tools and endoscopic instruments.

9. Biocompatible Surface Finishing Options for Implants and Tools

Surface finishing is crucial for components that come into contact with bodily tissues. CNC manufacturing provides options for surface polishing and other treatments to enhance biocompatibility and durability. These finishes are critical for parts like joint replacements and dental implants, where smooth surfaces reduce the risk of infection and promote compatibility with human tissue.

| Surface Finish | Benefit |

|---|---|

| Polished Titanium | Enhanced biocompatibility, reduced friction |

| Anodized Aluminum | Corrosion resistance, aesthetic appeal |

| Textured PEEK | Improved grip for surgical tools |

10. Increased Durability and Performance of Medical Devices

Medical devices and instruments are frequently subjected to rigorous sterilization and repeated use. CNC machining produces parts with the durability to withstand such conditions, ensuring long service life. This durability is especially important for medical instruments, which require both resilience and precision for repeated use in sterile environments.

Frequently Asked Questions (FAQs)

Q: What is the typical tolerance level achievable with CNC manufacturing for medical parts?

A: CNC machining can achieve tolerances as tight as ±0.01 mm, which is suitable for intricate medical applications like implants and surgical tools.

Q: How does CNC manufacturing benefit the production of patient-specific implants?

A: CNC machining allows for precise customization, creating implants that match the patient’s unique anatomy, thus improving comfort and compatibility.

Q: Is CNC manufacturing limited to metals, or can it be used with medical-grade plastics?

A: CNC machining can work with both metals and medical-grade plastics such as PEEK, allowing for versatility in medical device manufacturing.

Q: What role does surface finishing play in CNC machined medical parts?

A: Surface finishing enhances biocompatibility, durability, and performance, which is essential for implants and tools used in contact with bodily tissues.

Q: Can CNC machining meet the strict regulatory standards in the medical industry?

A: Yes, CNC machining can produce high-precision parts that adhere to the rigorous standards set for medical devices, ensuring safety and reliability.

In conclusion, CNC machining offers essential benefits for the medical industry, from unmatched precision and rapid prototyping to customization and material flexibility. For companies seeking high-quality CNC machining services, CNCRUSH stands out as a reliable partner. With over a decade of experience in CNC Milled parts and CNC Turned parts, CNCRUSH is dedicated to delivering precision CNC machining solutions that meet the strict demands of the medical, automotive, and industrial automation sectors.