The future of metal parts manufacturing is evolving at an unprecedented pace, driven by advances in CNC machining services, automation, and precision engineering. This shift is reshaping industries like automotive, machine building, and automation, creating exciting opportunities for manufacturers and clients alike.

With over 12 years of experience in providing high-quality CNC Milled parts and CNC Turned parts, CNCRUSH has emerged as a trusted partner for global clients. Our state-of-the-art facility in China delivers unparalleled expertise in precision machining. Whether you need prototypes, small batches, or large production runs, our focus on excellence ensures every part meets stringent standards.

Summary of Key Insights

Drawing from recent trends and predictions, this article explores the most impactful innovations in CNC machining and their implications for the future. These include automation, digitalization, material innovations, and the rise of smart factories. For those seeking top-tier CNC machining solutions, visit CNCRUSH to learn more about our custom machining services.

1. CNC Automation: The Future of Unmatched Efficiency

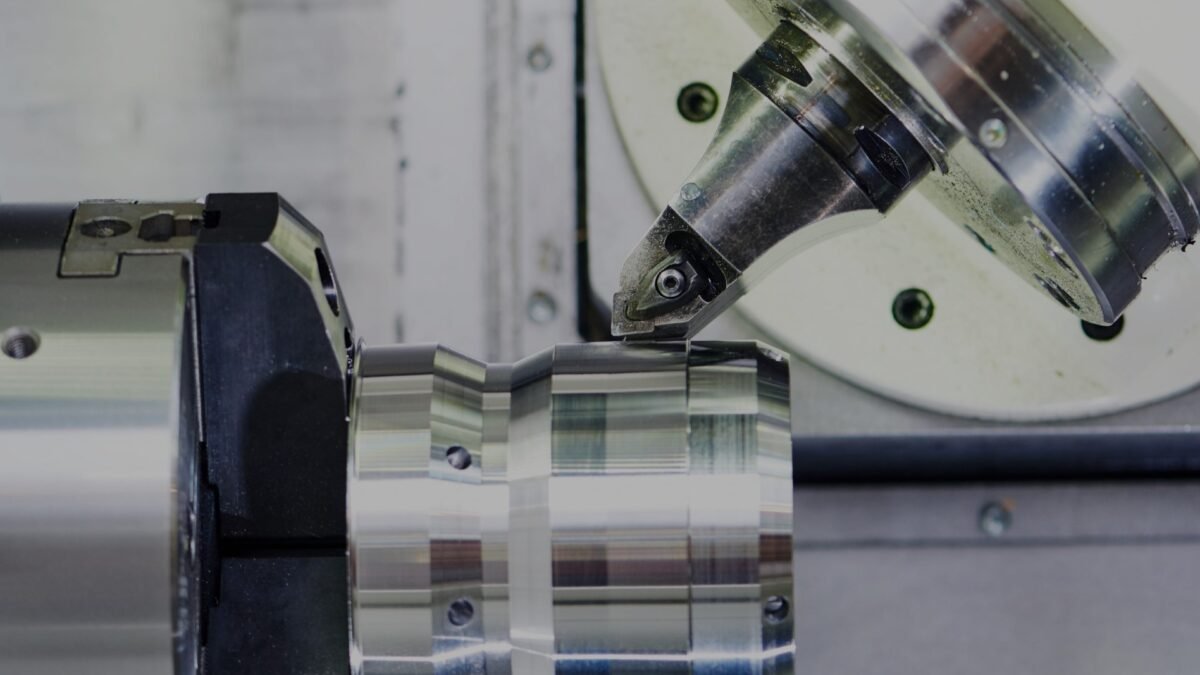

Automation in CNC machining is revolutionizing metal parts manufacturing, improving precision, consistency, and productivity.

Key Advancements:

- Robotic Integration: CNC machines equipped with robotic arms streamline tasks like material loading and unloading, reducing downtime.

- Lights-Out Manufacturing: Factories now operate without human supervision during off-hours, maximizing production capacity.

Example Impact:

Automotive companies are adopting robotic CNC machining for complex engine parts, enhancing both quality and speed.

CNCRUSH Advantage:

Our factory utilizes advanced CNC systems to deliver consistent, high-quality results. Explore our expertise in CNC machining for automotive parts.

2. Smart Factories and Digital Twins

The emergence of smart factories, driven by IoT and AI, marks a transformative era for CNC machining.

Benefits of Smart Factories:

- Real-Time Monitoring: Sensors track machine performance, ensuring proactive maintenance.

- Digital Twins: Virtual replicas of CNC processes optimize workflows, reducing errors.

| Traditional Factory | Smart Factory |

|---|---|

| Manual Monitoring | Real-Time IoT Sensors |

| Reactive Maintenance | Predictive Maintenance |

Sentiment Analysis:

Adopting these technologies can significantly reduce waste and improve customer satisfaction—a must-have for forward-thinking businesses.

3. Sustainable CNC Machining for Green Manufacturing

Sustainability is at the forefront of CNC Metal Parts Manufacturing advancements, driven by stricter environmental regulations.

Sustainable Practices:

- Using eco-friendly coolants and lubricants.

- Optimizing material usage to minimize waste.

- Incorporating renewable energy sources in factories.

At CNCRUSH, we are committed to reducing our carbon footprint by optimizing machining processes and material utilization.

4. Advanced Materials for CNC Metal Parts Manufacturing Parts

The demand for lightweight, durable, and innovative materials continues to grow in industries like automotive and automation.

| Material | Advantages |

|---|---|

| Aluminum Alloys | Lightweight, corrosion-resistant |

| Titanium | High strength-to-weight ratio, biocompatible |

| Composites | Excellent durability and heat resistance |

Future Outlook:

The use of composites and advanced alloys is expected to double by 2030.

5. High-Speed CNC Machining: Redefining Productivity

High-speed CNC machining reduces production time without compromising precision.

Applications:

- Rapid prototyping for the automotive sector.

- Mass production of precision components.

At CNCRUSH, our high-speed machining services deliver custom CNC solutions tailored to tight deadlines.

6. Custom CNC Solutions for Diverse Industries

Industries like aerospace, healthcare, and machine building increasingly rely on custom CNC solutions.

Examples:

- Medical Implants: CNC machining enables precision in crafting surgical implants.

- Aerospace Components: Lightweight, high-strength parts for aircraft structures.

Contact CNCRUSH for custom CNC Metal Parts Manufacturing tailored to your industry needs.

7. AI and Machine Learning in CNC Metal Parts Manufacturing

AI is unlocking new possibilities in CNC machining by optimizing tool paths and enhancing machine learning.

Innovations:

- AI-based error prediction.

- Automated design adjustments for better manufacturability.

Our CNC experts utilize AI to achieve unparalleled precision in both CNC Milled parts and CNC Turned parts.

8. The Role of CNC Machining in Automation and Robotics

Automation and robotics require precise and reliable components, often crafted using CNC Metal Parts Manufacturing.

Applications in Robotics:

- Custom joints and housings for robotic arms.

- Precision gears for automation systems.

CNCRUSH Expertise:

We specialize in CNC Metal Parts Manufacturing for robotic and automation parts, ensuring seamless integration with your systems.

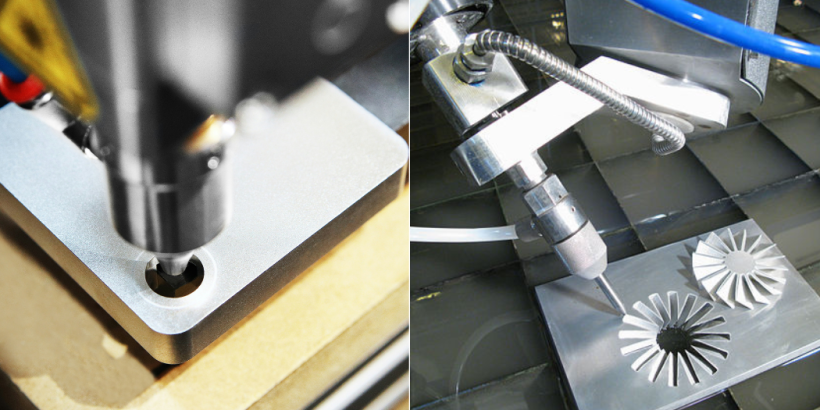

9. The Rise of Hybrid CNC Machines

Hybrid CNC machines combine traditional CNC processes with additive manufacturing, offering unmatched flexibility.

Advantages:

- Combining milling and 3D printing in a single setup.

- Cost-effective production of complex geometries.

Hybrid technologies are particularly valuable in prototyping and small-batch production.

10. Affordable CNC Machining: A Global Perspective

Global clients are seeking affordable CNC machining without compromising on quality.

Why Choose China?

- Competitive pricing due to lower operational costs.

- Skilled workforce with advanced machinery.

As a leading CNC factory in China, CNCRUSH delivers high-quality CNC Metal Parts Manufacturing services at a competitive price.

FAQ: Everything You Need to Know About CNC Metal Parts Manufacturing

1. What industries benefit most from CNC machining?

Industries like automotive, aerospace, healthcare, and automation rely heavily on CNC machining for precision parts.

2. What materials can be used for CNC machining?

Common materials include aluminum, steel, titanium, brass, and advanced composites.

3. Why choose CNCRUSH for CNC machining services?

With 12 years of expertise, CNCRUSH provides custom CNC solutions, focusing on quality, precision, and affordability.

Conclusion

The future of metal parts manufacturing lies in embracing advanced technologies, sustainability, and customized solutions. CNCRUSH stands at the forefront of this evolution, offering world-class CNC Metal Parts Manufacturing services. Whether you need CNC Milled parts or CNC Turned parts, our expert team ensures exceptional results tailored to your needs.

For high-quality machining solutions, visit CNCRUSH today!