CNC machining solutions have become a cornerstone of the medical sector, offering unmatched precision and reliability for life-saving applications. For over a decade, CNCRUSH has delivered high-quality CNC machining services, producing critical components for medical devices. By leveraging CNC milled parts and CNC turned parts, we provide custom solutions tailored to meet stringent medical industry requirements. Below, we explore the top CNC machining solutions for the medical sector, highlighting their importance and why CNCRUSH is your go-to partner for precision CNC machining in China.

1. The Role of CNC Machining in the Medical Industry

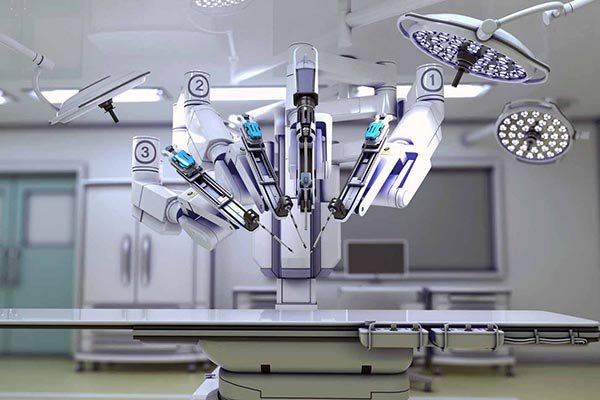

CNC machining is vital for manufacturing medical devices due to its ability to produce intricate parts with exacting tolerances. From surgical instruments to implantable devices, CNC machining ensures components meet safety and functional requirements.

Key Benefits:

- Precision: Essential for patient safety.

- Repeatability: Guarantees consistent results.

- Material Versatility: Processes a wide range of materials like titanium and stainless steel.

At CNCRUSH, our CNC machining services are trusted by global medical manufacturers for delivering unparalleled precision and consistency.

2. CNC Milled Parts for Medical Applications

CNC milling is ideal for creating complex geometries required in medical devices. Components such as surgical guides, custom prosthetics, and diagnostic tools are typically CNC milled for precision.

Use Cases:

- Surgical Tools: Accurate cutting edges ensure safe and effective procedures.

- Prosthetic Joints: Customized designs for patient-specific needs.

With advanced 3-axis and 5-axis machines, CNCRUSH excels in producing CNC milled parts that adhere to stringent medical standards.

3. CNC Turned Parts in the Medical Field

CNC turning is indispensable for manufacturing cylindrical medical components such as screws and rods for orthopedic applications.

Advantages:

- High-Speed Production: Reduces lead times.

- Tight Tolerances: Ensures component compatibility.

CNCRUSH’s CNC turned parts are engineered to perfection, making them suitable for the most demanding medical applications.

4. Precision Materials for Medical Components

Material selection is critical in the medical industry. Popular materials include:

| Material | Applications |

|---|---|

| Titanium | Implants, surgical instruments |

| Stainless Steel | Hypodermic needles, dental tools |

| Medical-Grade Plastics | Prosthetics, diagnostic equipment |

CNCRUSH’s material expertise ensures we meet the exacting requirements of the medical sector.

5. Custom CNC Solutions for Complex Medical Devices

Medical devices often demand unique solutions. Custom CNC machining allows for:

- Prototype Development: Shorten time-to-market for innovative devices.

- Design Flexibility: Tailor parts to specific patient needs.

CNCRUSH provides custom CNC solutions to streamline the production of complex medical devices, ensuring high-quality outcomes.

6. Compliance with Medical Standards

Meeting industry standards such as ISO 13485 is non-negotiable in medical manufacturing.

Why Compliance Matters:

- Patient Safety: Minimizes risks.

- Regulatory Approval: Facilitates global market entry.

CNCRUSH ensures all medical components meet stringent quality and regulatory requirements.

7. Advanced CNC Techniques for Enhanced Performance

State-of-the-art techniques like micro-machining and multi-axis machining enable the production of ultra-precise medical components.

Innovations Include:

- Micro-Machining: For intricate parts like stents.

- 5-Axis Machining: Reduces setups and increases accuracy.

At CNCRUSH, our advanced capabilities set us apart as leaders in precision CNC Machining solutions.

8. Scalability for Mass Production

CNC machining not only supports prototyping but also scales seamlessly for mass production.

Key Advantages:

- Consistency: Ensures uniform quality across large volumes.

- Cost-Effectiveness: Reduces per-unit costs.

With over 12 years of experience, CNCRUSH delivers scalable CNC machining solutions for medical manufacturers worldwide.

9. Reducing Lead Times with CNC Automation

Automation in CNC machining accelerates production timelines while maintaining high precision.

Benefits:

- Faster Turnaround: Meets tight deadlines.

- Error Reduction: Enhances product quality.

CNCRUSH’s automated systems optimize efficiency, ensuring timely delivery of CNC milled parts and CNC turned parts for the medical sector.

10. Sustainability in Medical CNC Machining

Sustainability is increasingly important in medical manufacturing. CNC machining supports green initiatives through:

- Material Efficiency: Reduces waste.

- Energy-Efficient Machines: Lowers carbon footprint.

As a responsible CNC Machining solutions provider, CNCRUSH prioritizes sustainable practices to align with our clients’ environmental goals.

Table: CNC Machining Processes for Medical Applications

| Process | Key Applications |

| CNC Milling | Prosthetics, diagnostic tools |

| CNC Turning | Orthopedic screws, rods |

| Micro-Machining | Stents, surgical implants |

| 5-Axis Machining | Complex geometries |

FAQ: CNC Machining solutions in the Medical Sector

Q1: Why is CNC machining preferred for medical devices?

A: CNC Machining solutions offers unmatched precision, repeatability, and material versatility, making it ideal for critical medical applications.

Q2: Can CNCRUSH handle custom medical projects?

A: Yes, we specialize in custom CNC solutions tailored to the unique demands of the medical sector.

Q3: What materials does CNCRUSH work with for medical components?

A: Our expertise includes titanium, stainless steel, and medical-grade plastics.

Conclusion

CNC machining solutions have revolutionized the medical sector by enabling the production of precise, reliable, and innovative components. CNCRUSH, with over 12 years of experience, is a trusted partner for high-quality CNC machining services. Whether you need CNC milled parts, CNC turned parts, or custom solutions, we deliver excellence for the medical industry and beyond. Visit CNCRUSH to learn more about our comprehensive CNC Machining solutions and how we can support your medical manufacturing needs.