Introduction

CNC machining has revolutionized the medical industry by enabling the production of high-precision components essential for healthcare advancements. At CNCRUSH, we specialize in delivering unparalleled CNC machining services for diverse industries, including the medical sector, automotive, machine building, and automation. With over 12 years of experience, our expertise lies in crafting CNC milled parts and CNC turned parts with precision and consistency. This article explores the transformative impact of CNC machining in the medical field, its challenges, and how CNCRUSH stands out as a trusted partner for your machining needs.

The Critical Role of CNC Machining in Healthcare

CNC machining offers unmatched precision, repeatability, and customization capabilities, making it indispensable in healthcare. From producing surgical instruments to manufacturing intricate implants, the role of CNC machining in advancing medical technology cannot be overstated. The ability to meet stringent industry standards ensures reliability, safety, and durability in critical medical applications.

Materials Used in Medical CNC Machining

The choice of materials is pivotal in medical CNC machining. Commonly used materials include:

- Titanium: Known for its strength, lightweight properties, and biocompatibility, it is ideal for implants.

- Stainless Steel: Widely used for surgical instruments due to its corrosion resistance.

- Medical-Grade Plastics: Materials like PEEK and PTFE are chosen for their flexibility, biocompatibility, and cost-effectiveness. At CNCRUSH, we work with a diverse range of materials to ensure compatibility with various medical applications while adhering to stringent industry standards.

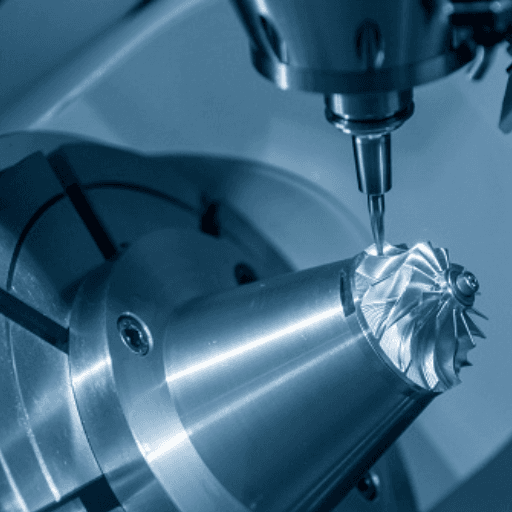

Advanced CNC Technologies in Medical Machining

Advanced CNC technologies such as multi-axis machining have redefined the capabilities of the medical manufacturing process.

- 5-Axis Machining: Allows for the production of complex geometries with minimal manual intervention, ensuring precision.

- High-Speed Machining: Reduces lead times without compromising on accuracy. CNCRUSH leverages cutting-edge equipment to deliver high-precision CNC milled and turned parts that meet the demands of the medical industry.

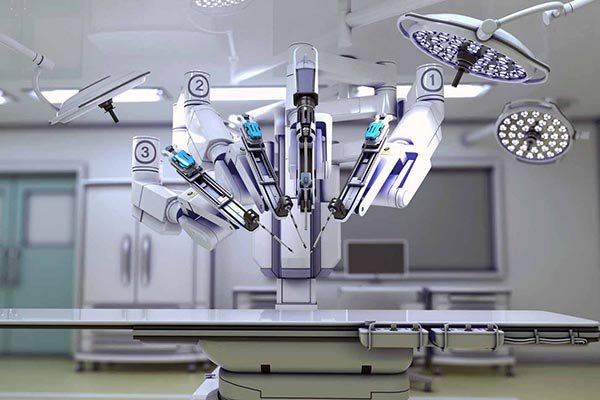

Key Applications of CNC Machining in the Medical Industry

CNC machining is crucial in producing a wide range of medical components, including:

- Surgical Instruments: Scalpels, forceps, and retractors.

- Orthopedic Implants: Hip and knee replacements.

- Dental Devices: Braces, crowns, and aligners.

- Diagnostic Equipment: MRI and CT scanner components. At CNCRUSH, our expertise enables us to cater to these diverse applications with efficiency and precision.

Ensuring Quality in Medical CNC Machining

The quality of medical components is critical to ensuring patient safety and device efficacy. At CNCRUSH, our rigorous quality control processes include:

- CMM Inspections: Coordinate Measuring Machines ensure precise dimensions.

- Micrometer Checks: Guarantee dimensional accuracy.

- Material Certifications: Verify compliance with medical-grade standards. These stringent measures allow us to deliver parts that exceed client expectations.

Cost-Efficiency of CNC Machining for Medical Parts

CNC machining reduces material waste and minimizes errors, offering a cost-effective solution for manufacturing medical components. CNCRUSH provides competitive pricing without compromising on quality, particularly for high-precision CNC milled and turned parts. By optimizing production processes, we ensure affordability and precision for projects of all sizes.

Embracing Sustainability in Medical CNC Machining

As the medical industry increasingly emphasizes sustainable manufacturing, CNC machining plays a pivotal role in achieving these goals. CNCRUSH adopts eco-friendly practices such as:

- Optimizing Material Usage: Reducing waste during machining.

- Energy-Efficient Equipment: Minimizing energy consumption. These practices align with global sustainability goals and reflect our commitment to environmentally responsible manufacturing.

Overcoming Challenges in Medical CNC Machining

The medical industry presents unique challenges, including:

- Regulatory Compliance: Meeting strict standards such as ISO 13485.

- Complex Designs: Manufacturing intricate components with tight tolerances. Our expertise at CNCRUSH enables us to address these challenges effectively, ensuring precision, compliance, and reliability in every project.

Why Choose CNCRUSH for Medical CNC Machining?

With a comprehensive suite of CNC machining services, CNCRUSH is the ideal partner for your medical manufacturing needs. Key reasons to choose us include:

- Extensive Experience: Over 12 years in the industry.

- Advanced Technology: State-of-the-art 5-axis machines.

- Global Reach: Trusted by clients worldwide for precision CNC milled and turned parts. Based in China, we combine advanced technology, skilled craftsmanship, and an unwavering commitment to quality to deliver exceptional results.

Table: CNC Machining Applications in Medicine

| Application | Example Products |

|---|---|

| Surgical Instruments | Scalpels, forceps, retractors |

| Orthopedic Implants | Hip and knee replacements |

| Dental Devices | Braces, crowns, aligners |

| Diagnostic Equipment | MRI components, CT scanner parts |

Table: Advantages of CNC production for Medical Components

| Benefit | Description |

| Precision | High accuracy for critical parts |

| Cost-Efficiency | Minimizes material waste |

| Scalability | Suitable for small to large volumes |

FAQ

1. What makes CNC production ideal for medical components? CNC production offers unparalleled precision and repeatability, essential for creating reliable medical devices.

2. What materials are commonly used in medical CNC production? Materials like titanium, stainless steel, and medical-grade plastics are commonly used.

3. How does CNCRUSH ensure quality in medical machining? We employ rigorous quality checks, including CMM and micrometer inspections, to ensure precision and reliability.

4. Can CNCRUSH handle custom medical machining projects? Yes, we specialize in custom CNC solutions tailored to meet specific client requirements.

5. What industries does CNCRUSH serve? We cater to the medical, automotive, machine building, and automation industries.

6. How does CNCRUSH incorporate sustainability into its processes? By optimizing material usage and using energy-efficient equipment, we align with global sustainability goals.

Conclusion

CNC machining is indispensable for advancing medical technology, offering precision, cost-efficiency, and reliability. At CNCRUSH, we combine expertise, cutting-edge technology, and a commitment to quality to deliver exceptional CNC machining solutions for the medical sector. Visit our website to learn how we can support your next project with high-quality CNC milled and turned parts tailored to your specific needs.