CNC Machining has revolutionized the medical device industry by enabling the production of highly precise and customized components essential for patient care. The integration of CNC technology has led to significant advancements in medical tools, implants, and diagnostic equipment, ensuring higher quality and reliability.

1. Advancements in Precision and Accuracy

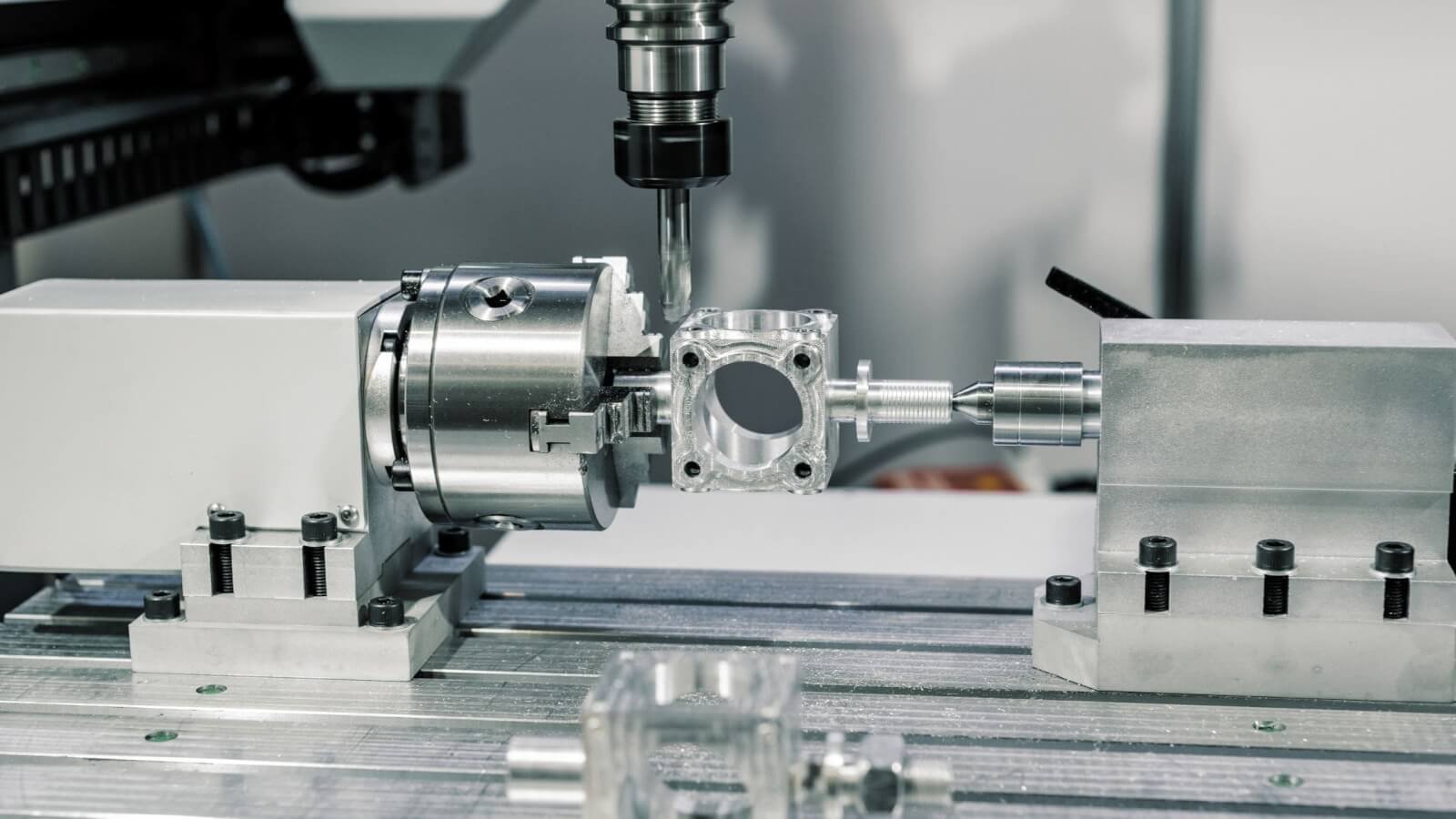

The medical industry demands exceptional precision, especially for devices such as surgical instruments, implants, and diagnostic tools. CNC machining meets these requirements by offering the capability to manufacture components with extremely tight tolerances, often within microns. This high level of precision ensures that devices perform optimally, minimizing the risk of complications during medical procedures. Continuous innovations in CNC technology, such as multi-axis machining and advanced tool path optimization, are pushing the boundaries of accuracy even further.

Additionally, precision is critical when working with delicate materials like medical-grade titanium, stainless steel, and specialized plastics. CNC machining ensures consistent quality throughout the production process, making it ideal for manufacturing life-saving devices where reliability is paramount.

2. Customization and Patient-Specific Solutions

As personalized medicine continues to grow, the demand for patient-specific medical devices has surged. CNC machining facilitates the production of fully customized implants, prosthetics, and surgical tools tailored to the unique anatomical requirements of each patient.

For example, custom orthopedic implants can be designed based on 3D scans of a patient’s bone structure, ensuring a perfect fit and improving healing outcomes. Similarly, dental crowns, bridges, and surgical guides can be crafted with high precision for individual patients. CNC machining’s ability to quickly adapt designs based on digital inputs makes it a crucial technology for the growing field of personalized healthcare.

3. Integration of Advanced Materials

The use of biocompatible materials in medical device manufacturing is critical to ensure patient safety and device longevity. CNC machining supports the processing of a wide range of advanced materials, including:

- Titanium Alloys: Known for their strength, corrosion resistance, and biocompatibility, commonly used for implants.

- Medical-Grade Stainless Steel: Often used for surgical instruments and orthopedic devices due to its durability and ease of sterilization.

- PEEK (Polyether Ether Ketone): A high-performance polymer used in spinal implants and dental devices.

CNC machining excels in handling these materials, ensuring clean cuts, minimal stress on the material, and high-quality surface finishes essential for medical applications.

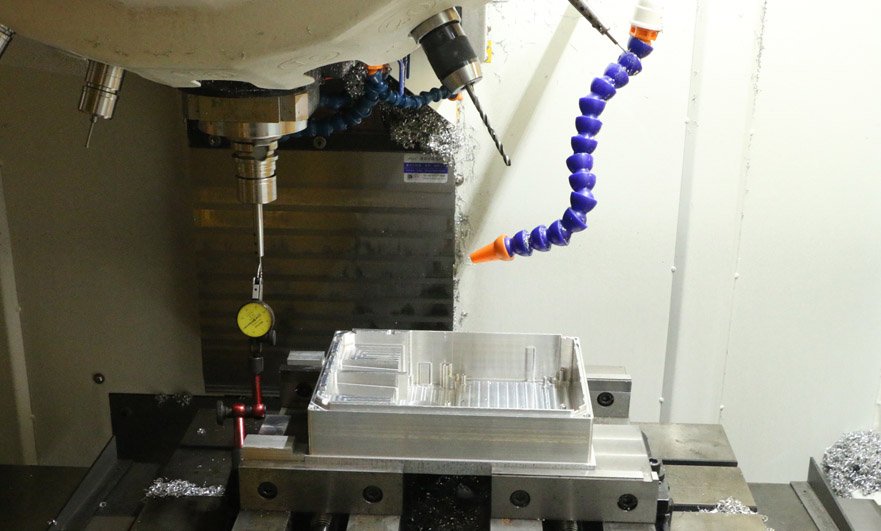

4. Enhanced Prototyping and Development

The medical device industry often requires rapid prototyping to test and validate new products before mass production. CNC machining offers fast turnaround times and flexibility, making it ideal for prototyping complex components.

This rapid prototyping capability allows medical companies to:

- Validate designs early in the development phase.

- Conduct functional testing with high-precision prototypes.

- Adjust designs quickly based on testing feedback.

By accelerating the development cycle, CNC machining helps medical innovations reach the market faster, ultimately benefiting patients through improved treatment options.

5. Automation and Efficiency in Production

Automation plays a crucial role in modern CNC machining, reducing manual intervention and increasing production efficiency. Advanced CNC machines equipped with robotic arms and automated tool changers can operate 24/7, producing medical components consistently with minimal human oversight.

Key benefits of automation in medical device manufacturing include:

- Reduced Error Rates: Automated systems minimize human error, ensuring consistent product quality.

- Higher Output: Ideal for large-volume production of disposable medical instruments or implants.

- Cost Reduction: Reduced labor costs and increased production speed lower overall manufacturing expenses.

6. Cost-Effectiveness and Accessibility

While CNC machining was once considered costly for medical applications, advancements in technology and automation have significantly reduced production costs. Today, CNC machining offers a cost-effective solution for both high-volume manufacturing and low-volume custom production.

This cost reduction benefits both medical device manufacturers and healthcare providers, leading to more affordable medical solutions without compromising on quality. By making precision manufacturing accessible, CNC machining helps improve global access to advanced medical treatments.

7. Regulatory Compliance and Quality Assurance

The medical industry is heavily regulated to ensure patient safety and device reliability. CNC machining aligns with these stringent requirements by offering precise control over manufacturing processes and comprehensive quality assurance protocols.

Key aspects of regulatory compliance include:

- ISO 13485 Certification: A standard for medical device quality management systems.

- Material Traceability: Ensuring all materials used meet medical-grade standards.

- Documentation: Detailed records of the manufacturing process for audit purposes.

CNC machining’s ability to maintain strict process control makes it easier for medical device manufacturers to meet FDA, CE, and other regulatory requirements.

8. Miniaturization of Medical Devices

The trend toward minimally invasive surgeries has driven demand for smaller, more intricate medical devices. CNC machining excels in producing miniature components with exceptional accuracy, essential for tools used in endoscopic surgeries and micro-surgical instruments.

Applications of CNC machining in miniaturized devices include:

- Micro-implants: Such as cochlear implants and tiny bone screws.

- Microsurgical Tools: Designed for delicate operations like eye surgeries.

The precision of CNC machining ensures that even the smallest components meet strict performance standards.

9. Global Collaboration and Manufacturing

CNC machining has enabled global collaboration by allowing companies to source high-quality medical components from manufacturers worldwide. Companies like CNCRUSH, with over 12 years of CNC machining experience, contribute to the global supply chain by providing precision parts for medical devices across different regions.

By partnering with experienced CNC machining facilities, medical device manufacturers can ensure consistent quality, even when outsourcing production internationally.

10. Future Trends and Innovations

The future of CNC machining in the medical device industry is set for significant advancements, including:

- AI-Enhanced Machining: Artificial intelligence for real-time process optimization.

- 5-Axis Machining: Enabling the production of even more complex geometries.

- Hybrid Manufacturing: Combining CNC machining with additive manufacturing for greater design flexibility.

These innovations will continue to drive improvements in medical device performance, patient outcomes, and manufacturing efficiency.

Table 1: Comparison of Traditional Manufacturing vs. CNC Machining in Medical Device Production

| Aspect | Traditional Manufacturing | CNC Machining |

|---|---|---|

| Precision | Limited | High |

| Customization | Challenging | Easily Achievable |

| Production Speed | Slower | Faster |

| Material Compatibility | Limited | Extensive |

| Cost-Effectiveness | Variable | Increasingly Affordable |

| Regulatory Compliance | Complex | Streamlined |

| Scalability | Limited | Highly Scalable |

| Prototyping Efficiency | Low | High |

| Automation Integration | Minimal | Advanced |

| Miniaturization Capability | Limited | Superior |

Table 2: Key Benefits of CNC Machining in Medical Device Manufacturing

| Benefit | Description |

| Enhanced Precision | Achieves tight tolerances essential for medical devices. |

| Rapid Prototyping | Accelerates development and testing of new devices. |

| Customization | Allows for patient-specific solutions improving treatment outcomes. |

| Material Versatility | Compatible with a wide range of biocompatible materials. |

| Cost Efficiency | Reduces manufacturing costs, making devices more accessible. |

| Consistency and Quality | Ensures uniformity across large production batches. |

| Compliance with Regulations | Meets stringent medical industry standards. |

| Support for Miniaturization | Enables production of small, intricate components for advanced medical technologies. |

| Automation and Efficiency | Incorporates automated processes reducing errors and increasing productivity. |

| Global Manufacturing Support | Facilitates collaboration and production across international borders. |

Frequently Asked Questions (FAQ)

Q1: What is CNC Machining? A1: CNC (Computer Numerical Control) Machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process allows for the production of highly precise and complex parts, essential in industries like medical device manufacturing.

Q2: Why is CNC Machining important in the medical device industry? A2: CNC Precision Machining provides the precision, customization, and efficiency required to produce medical devices that meet strict regulatory standards and patient-specific needs.

Q3: How does CNC Machining contribute to the customization of medical devices? A3: CNC precision machining allows manufacturers to create highly personalized devices tailored to individual patient needs, such as custom implants and surgical tools.