CNC Machining plays a critical role in the aerospace industry, offering unmatched precision, reliability, and efficiency for manufacturing complex components vital for aircraft safety and performance. With over 12 years of expertise, CNCRUSH provides world-class CNC machining services from China, specializing in CNC Milled parts and CNC Turned parts for demanding industries such as aerospace, automotive, machine building, and automation.

The Importance of CNC Machining in the Aerospace Industry

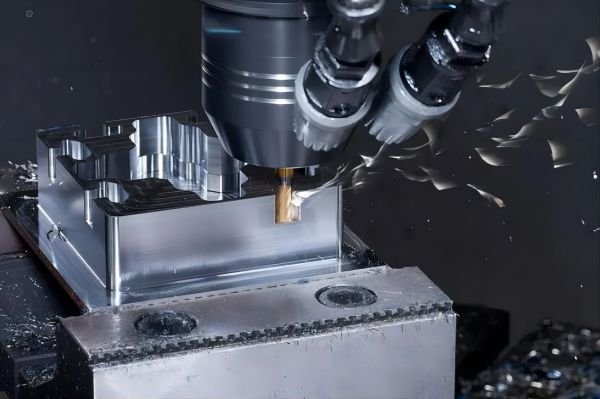

CNC Machining is essential for aerospace manufacturing due to its ability to produce parts with ultra-tight tolerances and complex geometries. High-precision components are crucial for aircraft performance and safety, where even the smallest deviations can impact functionality. CNC machining enables repeatability, making it indispensable for mission-critical aerospace applications.

Benefits of CNC Machining for Aerospace Applications

- Unmatched Accuracy: CNC machining ensures precise component manufacturing, minimizing errors and reducing waste.

- Material Versatility: Aerospace parts often require high-performance materials like aluminum, titanium, and steel, all supported by CNC machining processes.

- Consistency: Automated processes ensure uniform quality and repeatability across production runs.

- Speed and Efficiency: CNC technology accelerates production timelines while maintaining superior quality and precision.

- Scalability: CNC machining is ideal for both prototyping and full-scale production, making it adaptable to project needs.

Key CNC Machining Services for Aerospace Components

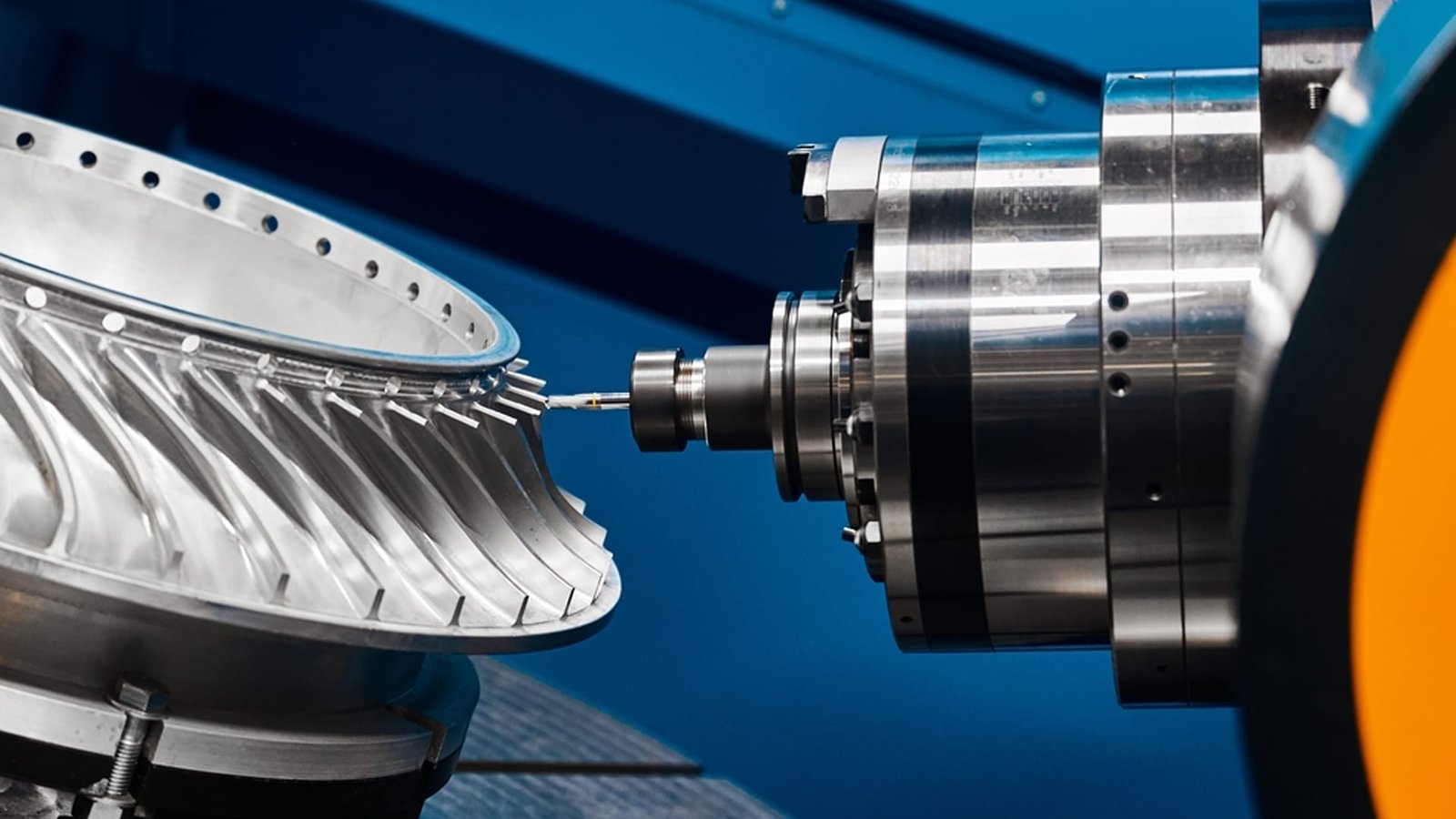

1. CNC Milled Parts for Aerospace

CNC milling is ideal for creating complex aerospace components such as turbine blades, brackets, engine mounts, and structural panels. It offers precision for intricate designs and tight tolerances.

2. CNC Turned Parts for Aerospace

CNC turning is essential for manufacturing cylindrical aerospace parts, including shafts, bushings, and fasteners. This process delivers exceptional accuracy for round components requiring smooth finishes and exact dimensions.

3. CNC Prototyping for Aerospace Innovations

Prototyping allows aerospace firms to test and validate designs before mass production. This reduces costly design errors and ensures the final parts meet all performance requirements before production scaling.

4. CNC Machining for Custom Aerospace Components

Custom CNC machining enables the production of unique and specialized aerospace parts tailored to specific design requirements, ensuring compatibility with cutting-edge technologies and advancements.

5. CNC Machining for Large-Scale Aerospace Projects

Large-scale aerospace manufacturing relies on CNC machining for producing essential aircraft components, including landing gear components, engine casings, and fuselage reinforcements, maintaining high standards of consistency and durability.

Materials Commonly Used in CNC Precision Machining for Aerospace

- Aluminum: Lightweight, corrosion-resistant, and widely used for structural components.

- Titanium: Known for its high strength, heat resistance, and fatigue performance, often used in engine parts.

- Stainless Steel: Durable and resistant to extreme conditions, ideal for fasteners and casing applications.

- Inconel: High-performance superalloy used in high-temperature aerospace applications.

Why Choose CNCRUSH for Aerospace CNC Machining?

- 12+ Years of Expertise: Trusted experience in CNC manufacturing services across aerospace and other demanding industries.

- Advanced Equipment: State-of-the-art CNC mills and lathes for superior precision and efficiency.

- Comprehensive Quality Control: Equipped with CMM inspections, height gauges, and hardness testers for top-quality assurance.

- Global Client Base: Trusted by companies worldwide for exceptional CNC manufacturing services.

Table 1: Material Comparison for Aerospace Components

| Material | Key Benefits | Common Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Structural components |

| Titanium | High strength, heat-resistant | Engine parts, landing gear |

| Stainless Steel | Durable, extreme conditions | Fasteners, casings, housings |

| Inconel | Heat-resistant superalloy | Exhaust components, turbines |

Table 2: Key CNC Machining Services Offered by CNCRUSH

| Service | Application | Benefit |

| CNC Milled Parts | Turbine blades, brackets | Complex shapes, high accuracy |

| CNC Turned Parts | Shafts, bushings, fasteners | Cylindrical precision, smooth finishes |

| CNC Prototyping | Design validation testing | Reduces design errors, accelerates development |

| Custom CNC Parts | Specialized aerospace components | Tailored designs, high customization |

| Large-Scale CNC Machining | Fuselage, engine components | Consistency for mass production |

Conclusion

CNC manufacturing plays a transformative role in modern aerospace manufacturing, providing unmatched precision, reliability, and efficiency for mission-critical components. CNCRUSH, with over a decade of specialized expertise, stands out as a trusted CNC manufacturing partner, offering CNC Milled parts and CNC Turned parts with exceptional quality standards. If you’re seeking superior aerospace CNC manufacturing services, explore our expertise at CNCRUSH to elevate your components with precision engineering.

FAQ Section:

Q: What makes CNC machining ideal for aerospace components? A: CNC manufacturing offers unparalleled precision, consistency, and the ability to work with aerospace-grade materials, ensuring top-quality parts for critical applications.

Q: What aerospace components can be produced using CNC machining? A: CNC manufacturing can create turbine blades, brackets, fasteners, shafts, engine components, and structural supports with superior accuracy.

Q: Why choose CNCRUSH for aerospace CNC machining? A: CNCRUSH combines advanced equipment, over 12 years of industry experience, and rigorous quality control to deliver superior aerospace components on time and within specifications.

Q: Can CNCRUSH handle both prototypes and full-scale aerospace production? A: Yes, CNCRUSH specializes in both CNC prototyping for design validation and large-scale production for aerospace projects.

Q: How can I get a quote from CNCRUSH? A: Visit CNCRUSH to contact our team for a personalized CNC manufacturing quote tailored to your project needs.