Explore how CNC machining for aerospace is transforming the industry. With over 12 years of experience in CNC milling and turning, CNCRUSH offers high-quality custom CNC machining services for aerospace parts and more.

Introduction

CNC machining plays an integral role in various industries, particularly aerospace. As the demand for precision and durability in aerospace components grows, CNC machining has proven to be the most efficient and cost-effective solution. In this comprehensive guide, we will delve into the significance of CNC machining in the aerospace sector, discuss how it enhances production quality, and explore how you can access these expert services through CNCRUSH, a China-based factory with 12 years of experience in CNC milling and turning.

Table of Contents

- The Role of CNC Machining in Aerospace

- How CNC Milled Parts Shape Aerospace Innovation

- The Importance of CNC Turned Parts in Aerospace

- Key Benefits of CNC precision Machining for Aerospace

- CNC Machining vs. Traditional Manufacturing for Aerospace Parts

- Materials Used in Aerospace CNC precision Machining

- How CNC precision Machining Boosts Aerospace Part Precision and Reliability

- The Process of CNC precision Machining for Aerospace Components

- Applications of CNC Machined Parts in Aerospace

- Choosing the Right CNC precision Machining Service for Aerospace Parts

1. The Role of CNC Machining in Aerospace

CNC machining has become indispensable to the aerospace industry due to its ability to produce parts that meet stringent quality standards. Aerospace components, such as engine parts, brackets, and structural elements, require high precision, which CNC machining can deliver consistently. The advanced technology behind CNC machines ensures that complex geometries can be produced with high accuracy, ensuring the safety and efficiency of aircraft.

At CNCRUSH, our expertise in CNC milling and turning enables us to offer high-quality CNC machining services that aerospace companies trust to produce essential parts that meet global standards.

2. How CNC Milled Parts Shape Aerospace Innovation

CNC milled parts are essential for aerospace because they enable the production of intricate and complex components with tight tolerances. These parts are typically used in structural elements, such as wings, fuselage, and control surfaces. The precision and surface finish provided by CNC milling allow these parts to function flawlessly under high-stress conditions.

In our CNC manufacturing facility, we specialize in CNC Milled parts, ensuring that each component meets the high-quality standards required in the aerospace industry. With advanced 3-axis, 4-axis, and 5-axis milling machines, we can manufacture parts with detailed specifications for aerospace applications.

3. The Importance of CNC Turned Parts in Aerospace

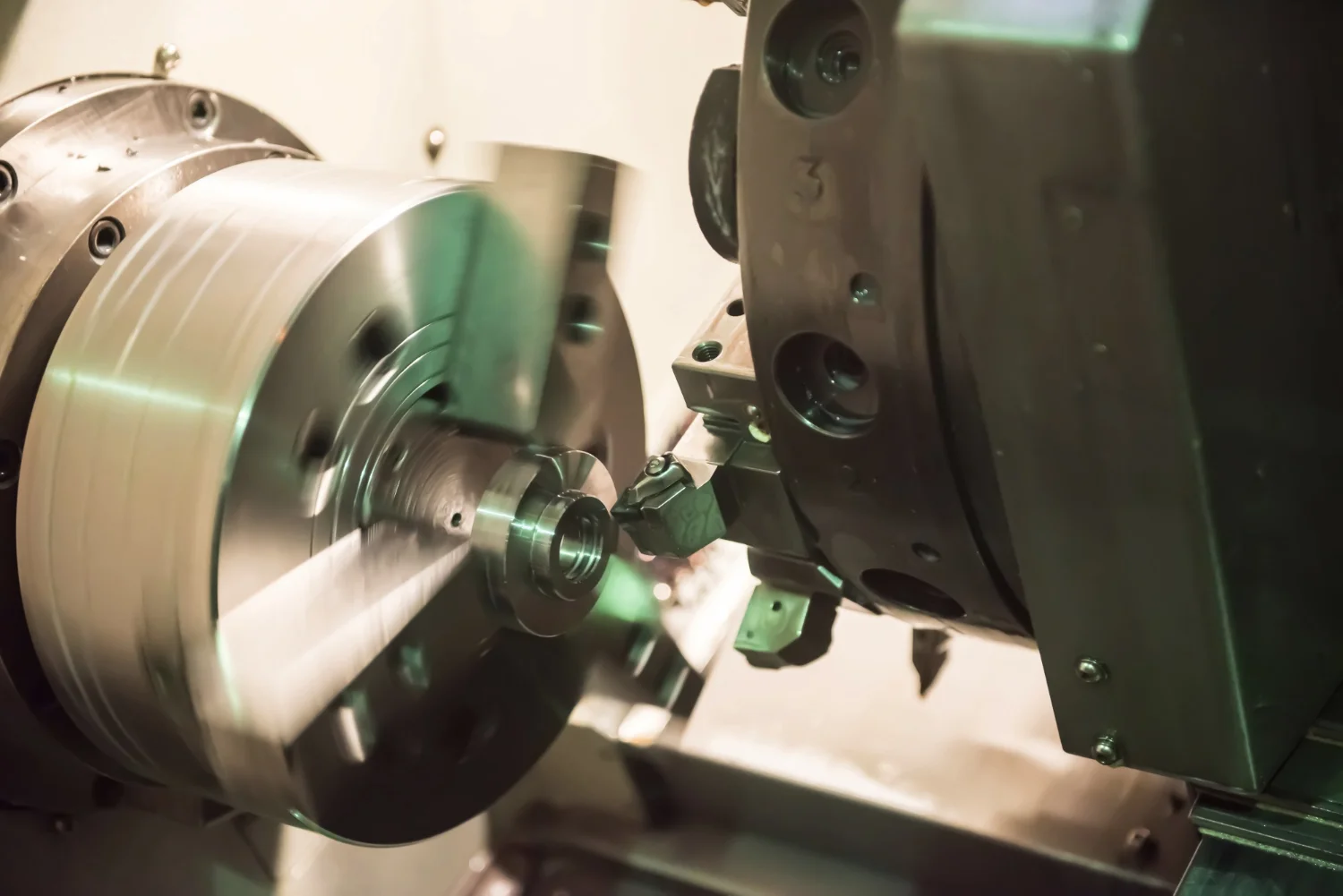

CNC turning is another vital process in aerospace component manufacturing. CNC turned parts, like shafts, spindles, and cylindrical components, are integral to ensuring smooth mechanical operations in aircraft systems. The high precision of CNC turning makes it ideal for producing parts with exact dimensions and a superior surface finish, which are crucial for the performance of aerospace machinery.

At CNCRUSH, we offer CNC Turned parts using state-of-the-art lathes to produce perfectly turned components that meet aerospace requirements for strength, durability, and performance.

4. Key Benefits of CNC Machining for Aerospace

CNC machining offers several key benefits that make it a preferred choice for aerospace manufacturing:

- Precision: CNC machines can produce parts with tolerances as tight as 0.0001 inches, which is critical in aerospace applications.

- Consistency: CNC manufacturing ensures that each part produced is identical, reducing the risk of defects and ensuring uniformity.

- Material Efficiency: CNC manufacturing minimizes waste, which is a significant advantage when working with expensive materials like titanium and high-strength alloys.

- Flexibility: CNC machines can handle various materials and complex part geometries, making them ideal for custom aerospace components.

By leveraging precision CNC machining and custom CNC solutions, CNCRUSH delivers aerospace components that meet the highest standards in the industry.

5. CNC Machining vs. Traditional Manufacturing for Aerospace Parts

When compared to traditional manufacturing methods, CNC manufacturing offers clear advantages. Traditional methods often require extensive labor, which can lead to inconsistencies and errors. CNC manufacturing, on the other hand, is automated and digitally controlled, ensuring accuracy and repeatability. Additionally, CNC manufacturing reduces lead times and allows for faster prototyping, which is essential in the fast-paced aerospace industry.

6. Materials Used in Aerospace CNC Machining

Aerospace parts must be made from materials that can withstand extreme conditions, such as high pressure, temperature, and wear. CNC manufacturing can handle a variety of materials that are commonly used in the aerospace industry, including:

- Aluminum: Lightweight and durable, often used in structural components.

- Titanium: Strong and corrosion-resistant, ideal for high-stress parts.

- Steel: Provides strength and durability for critical components.

- Composites: Used in parts where lightweight and strength are essential.

At CNCRUSH, we specialize in CNC machining aluminum, CNC machining steel, and CNC machining titanium, offering CNC machining services that meet aerospace material specifications.

7. How CNC Machining Boosts Aerospace Part Precision and Reliability

The high precision offered by CNC manufacturing is indispensable in the aerospace industry. Aerospace components often need to fit perfectly into complex systems where even a small deviation can have catastrophic consequences. With CNC manufacturing, parts are manufactured with unparalleled precision, ensuring that every component meets exacting specifications and functions reliably over long periods.

8. The Process of CNC Machining for Aerospace Components

The process of CNC precision machining for aerospace parts begins with creating a 3D model of the part using CAD software. Once the design is complete, the part is programmed into a CNC machine, which uses various tools to cut, mill, or turn the material into the final shape. Advanced machines, like those at CNCRUSH, can handle complex geometries and high-precision requirements, ensuring that aerospace parts are fabricated to the highest standards.

9. Applications of CNC Machined Parts in Aerospace

CNC machined parts are used in virtually every aspect of aerospace manufacturing. Some common applications include:

- Engine Components: Parts like turbine blades, casings, and rotors.

- Structural Elements: Wings, fuselage, and frames.

- Landing Gear Components: Precision components that need to endure heavy loads.

- Aircraft Interiors: High-quality parts for cabin features and seating.

At CNCRUSH, we provide custom CNC precision machining solutions for all types of aerospace components, ensuring that each part meets the required functionality and safety standards.

10. Choosing the Right CNC Machining Service for Aerospace Parts

Selecting the right CNC precision machining service for aerospace parts is critical to ensuring the quality and performance of the components. Factors to consider include:

- Experience: Look for a CNC precision machining service with a proven track record in aerospace.

- Technology: Ensure that the facility is equipped with the latest CNC machines and technology.

- Quality Control: Choose a service that uses advanced inspection equipment, such as CMM and hardness testers, to verify the precision of each part.

With over 12 years of experience in providing CNC precision machining services, CNCRUSH is well-equipped to handle all your aerospace machining needs with the utmost precision and quality.

Table: Comparison of CNC Machining and Traditional Methods in Aerospace

| Feature | CNC Machining | Traditional Methods |

|---|---|---|

| Precision | High (0.0001 inch) | Low (varies) |

| Material Waste | Low | High |

| Lead Time | Short | Long |

| Customization | High | Limited |

| Labor Cost | Low | High |

FAQ

- What materials are best suited for CNC precision machining in aerospace?

- Common materials include aluminum, titanium, steel, and composite materials, depending on the part’s application.

- How accurate is CNC machining for aerospace parts?

- CNC machining offers extreme accuracy, with tolerances as tight as 0.0001 inches, essential for aerospace applications.

- Why should I choose CNCRUSH for aerospace CNC machining?

- With over 12 years of experience and a commitment to CNC precision machining and high-quality CNC services, CNCRUSH delivers top-tier aerospace components.

- Can CNCRUSH handle custom aerospace parts?

- Yes, CNCRUSH specializes in custom CNC solutions, providing tailored services for unique aerospace component requirements.

Conclusion

CNC machining has revolutionized aerospace manufacturing, offering unparalleled precision, speed, and material efficiency. As a trusted provider of CNC machining services, CNCRUSH brings over 12 years of experience in producing CNC Milled parts and CNC Turned parts for aerospace applications. Whether you’re in need of engine components or structural elements, CNCRUSH delivers high-quality, reliable parts that meet aerospace standards. Visit cncrush.com to discover more about how our CNC manufacturing services can elevate your aerospace projects.