Introduction

5-Axis CNC machining has revolutionized the manufacturing industry, becoming a cornerstone for precision and versatility in metalworking. With the capacity to handle complex geometries, this advanced machining method has propelled industries like automotive, machine building, and automation to new heights. At CNCRUSH, a leading CNC machining service provider based in China with over 12 years of expertise, we specialize in CNC Milled parts and CNC Turned parts, offering custom CNC solutions to clients worldwide. In this article, we delve into the transformative impact of 5-Axis CNC machining, presenting in-depth insights into its benefits, applications, and why CNCRUSH is the ideal partner for your CNC machining needs.

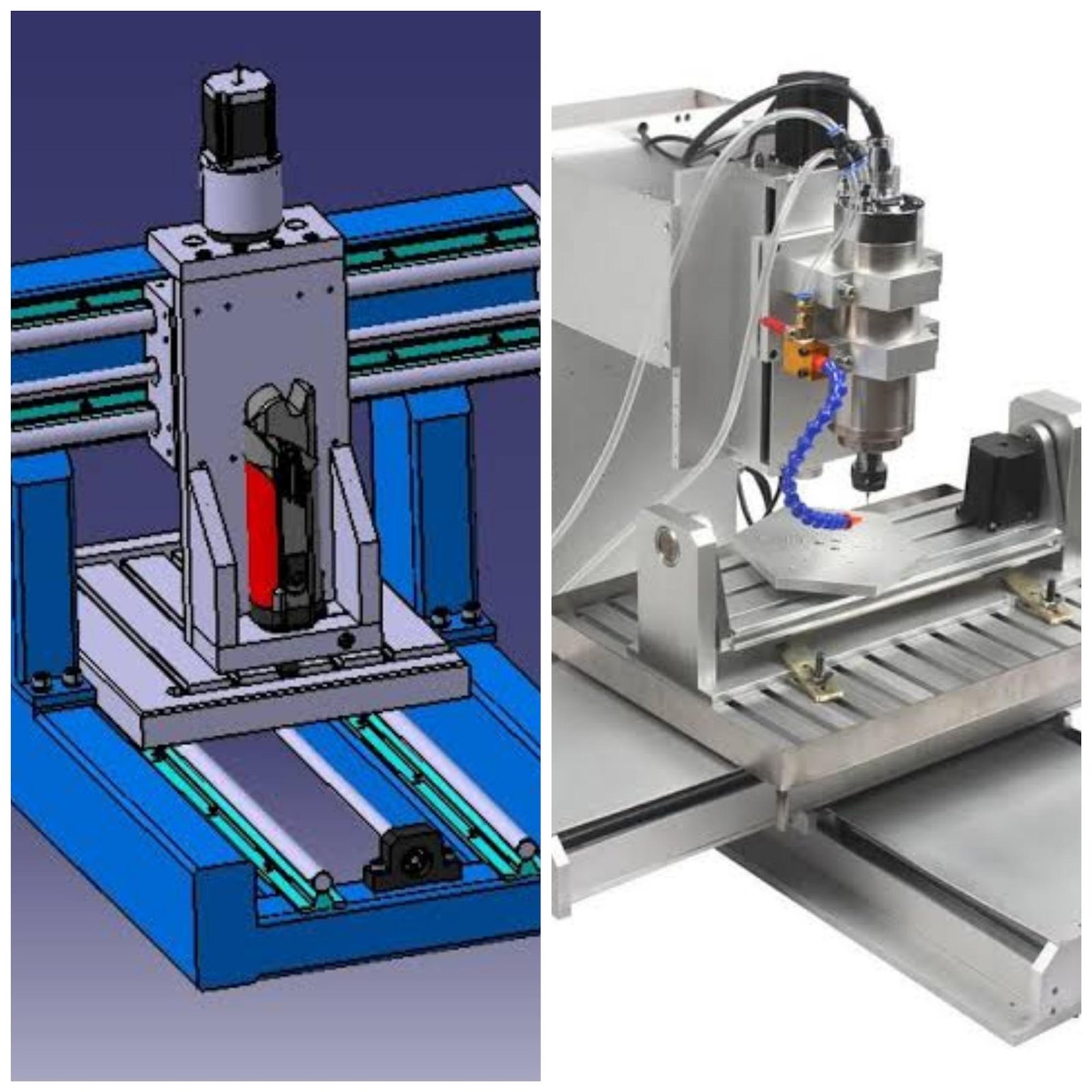

What Is 5-Axis CNC Machining?

Before diving into its advantages, it is essential to understand what 5-Axis CNC machining entails. Unlike traditional 3-axis machines, which move tools along three linear axes (X, Y, and Z), 5-axis machines add rotational motion around two additional axes, A and B. This capability allows for unparalleled precision, efficiency, and versatility in creating intricate parts.

1. Enhanced Precision and Accuracy

5-Axis CNC machining is renowned for delivering exceptional precision, crucial for industries where tolerances are minimal. This method eliminates multiple setups by machining parts in a single operation, reducing errors caused by repositioning.

At CNCRUSH, our state-of-the-art equipment ensures precise machining of CNC Milled parts and CNC Turned parts, meeting even the most stringent industry standards.

Key Benefits:

- Reduced setup errors

- Perfect for intricate geometries

- Reliable production of consistent parts

2. Increased Efficiency and Cost Savings

Time is money in manufacturing, and 5-Axis CNC machining dramatically reduces lead times by completing multiple machining processes in a single setup. This efficiency translates to lower labor costs and reduced material waste.

How CNCRUSH Delivers:

- Optimized machining strategies to reduce waste

- Competitive pricing without compromising quality

- Tailored solutions for automotive and machine-building sectors

3. Versatility in Material Options

One of the standout features of 5-Axis CNC machining is its ability to handle a diverse range of materials. Whether working with aluminum, steel, titanium, or plastics, this technology accommodates various industries’ needs.

Materials We Process:

- Aluminum for lightweight automotive components

- Steel for robust machine-building parts

- Plastics for automation applications

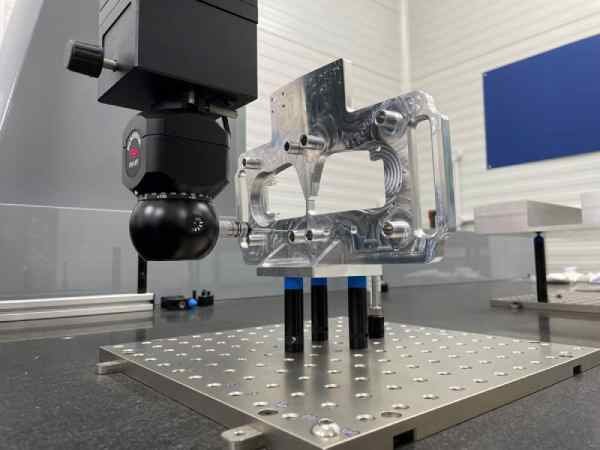

4. Complex Geometries Made Easy

The ability to machine complex shapes is a game-changer in metalworking. 5-Axis CNC machining enables the creation of parts with intricate designs that would be impossible or highly inefficient with traditional methods.

Applications:

- Automotive components with advanced aerodynamics

- Automation systems requiring high precision

- Custom CNC solutions for unique designs

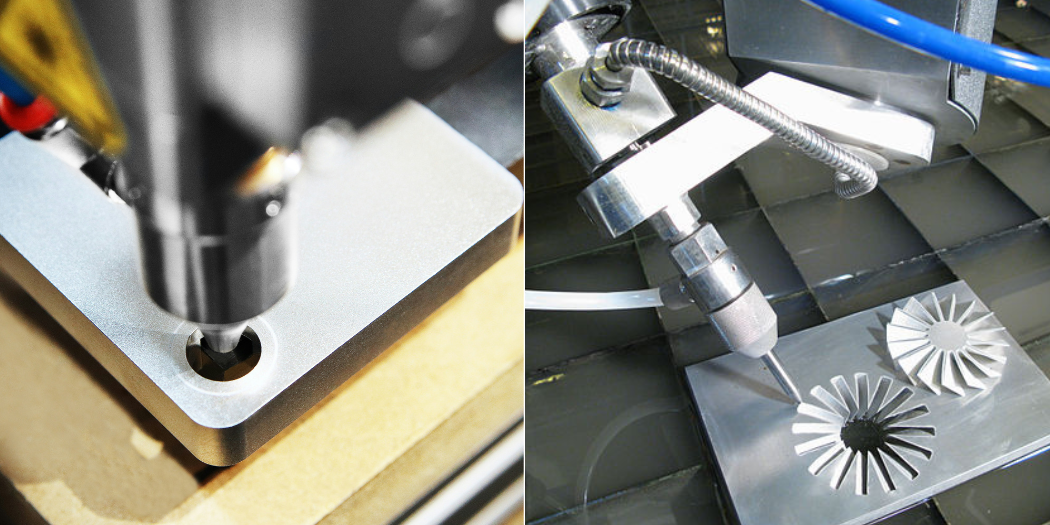

5. Reduced Tool Wear and Longer Lifespan

By optimizing tool angles and minimizing vibration, 5-Axis CNC machining prolongs the lifespan of cutting tools. This feature not only reduces operating costs but also ensures consistent part quality.

Advantages:

- Lower tool replacement costs

- Consistent machining performance

- Ideal for high-volume production

6. Improved Surface Finishes

Achieving a high-quality surface finish is critical in industries like automotive and aerospace. The ability of 5-Axis machines to maintain optimal cutting angles results in smoother surfaces and eliminates the need for extensive post-processing.

Why CNCRUSH Excels:

- Superior surface finishes for CNC Turned parts

- Minimal secondary operations

- Attention to detail in every project

7. Scalability for Prototyping and Production

Whether you need a prototype or a large production run, 5-Axis CNC machining scales effortlessly. At CNCRUSH, we cater to both small and large volumes, ensuring flexibility and adaptability for our clients.

Our Services Include:

- CNC prototype machining for product development

- High-quality CNC machining for metal and plastic parts

- Scalable solutions tailored to your needs

Table: 5-Axis CNC Machining vs. 3-Axis CNC Machining

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Precision | Moderate | High |

| Setup Time | Multiple setups required | Single setup |

| Suitable for Complex Parts | Limited | Excellent |

| Tool Wear | Higher | Lower |

| Surface Finish | Standard | Superior |

Applications of 5-Axis CNC Machining

- Aerospace Components: Lightweight yet strong parts for aircraft structures.

- Medical Devices: Surgical instruments and implants requiring high precision.

- Automotive Parts: Complex geometries for engine and transmission components.

- Automation Systems: Precision components for robotics and industrial systems.

Table: Industries Benefiting from 5-Axis CNC Machining

| Industry | Example Applications |

| Aerospace | Jet engine components |

| Medical | Prosthetics and implants |

| Automotive | Engine blocks, gears |

| Automation | Robotic arms, sensors |

FAQ

1. What is 5-Axis CNC Machining? 5-Axis CNC machining involves the movement of tools along five axes, allowing for precise and complex part creation.

2. Why choose 5-Axis CNC machining for metalworking? It offers unmatched precision, reduced setup times, and the ability to handle complex geometries.

3. What industries benefit most from 5-Axis CNC machining? Industries such as aerospace, automotive, medical, and automation gain significant advantages.

4. How does CNCRUSH support 5-Axis CNC machining projects? We provide high-quality CNC machining services, specializing in CNC Milled parts and CNC Turned parts with over 12 years of expertise.

5. Is 5-Axis CNC machining cost-effective? Yes, it reduces material waste and labor costs while improving efficiency.

Why Choose CNCRUSH?

With a legacy spanning over a decade, CNCRUSH is a trusted name in the CNC machining industry. Our commitment to excellence, state-of-the-art equipment, and expertise in CNC Milled parts and CNC Turned parts make us the ideal partner for your projects. Whether you’re in the automotive, machine-building, or automation sectors, we deliver precision, quality, and reliability.

Visit our website at CNCRUSH to explore our services and discover how we can bring your projects to life.