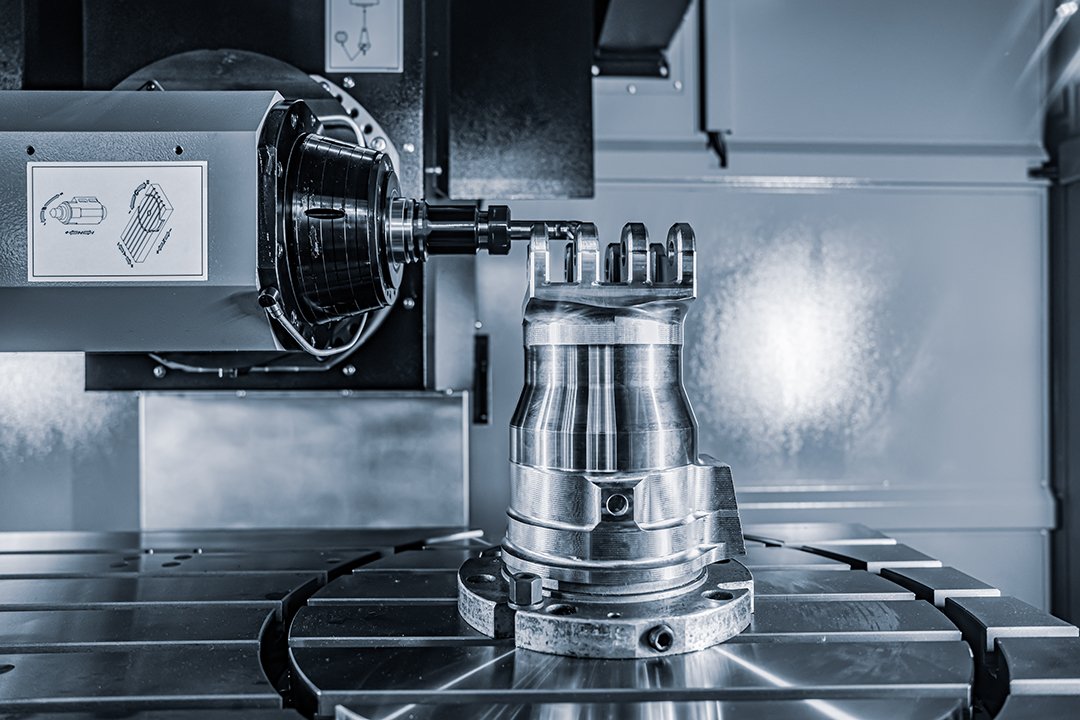

CNC machining has transformed manufacturing processes across industries, especially for materials like stainless steel, which demand precision, strength, and versatility. This modern technique offers unparalleled accuracy and efficiency, making it an essential tool for producing high-quality components in industries like automotive, machine building, and automation.

At CNCRUSH, we bring over 12 years of experience to the table, delivering CNC Milled parts and CNC Turned parts for clients worldwide. As a trusted China CNC factory, we specialize in CNC machining services for stainless steel and other materials, ensuring consistent quality, scalability, and affordability. This article will explore the five most significant benefits of CNC machining for stainless steel parts, illustrating how it can elevate your manufacturing processes.

Why CNC Machining Is Perfect for Stainless Steel

Stainless steel is one of the most popular materials in modern manufacturing due to its durability, corrosion resistance, and aesthetic appeal. However, it is also challenging to machine, as its toughness and thermal properties can cause tool wear and inaccuracies in traditional methods.

CNC machining solves these challenges through automation, precision, and advanced tooling, ensuring that stainless steel parts meet stringent specifications without excessive wear or waste. Below, we explore the top five benefits of CNC machining for stainless steel, backed by data and real-world examples.

1. Unmatched Precision and Consistency

The foremost advantage of CNC machining is its ability to produce parts with unmatched precision and consistency. This is particularly crucial when working with stainless steel, where deviations in size or shape can compromise functionality.

Why Precision Matters for Stainless Steel:

- Tight Tolerances: CNC machines can achieve tolerances as fine as ±0.005mm, ensuring every part meets exact specifications.

- Repeatability: Whether producing ten parts or ten thousand, CNC machining delivers consistent quality across the entire production run.

- Surface Finish: Advanced CNC milling and turning techniques ensure smooth, burr-free finishes, essential for stainless steel components in automotive or medical applications.

At CNCRUSH, our cutting-edge equipment and skilled engineers ensure that every stainless steel component meets or exceeds client expectations, whether it’s a complex CNC Turned part for machinery or a high-precision CNC Milled part for automation systems.

2. Cost Efficiency Through Reduced Waste

Stainless steel is an expensive material, and minimizing waste is crucial for cost-effective manufacturing. Traditional machining methods often result in significant material loss due to human error or inefficient cutting techniques.

How CNC Machining Reduces Waste:

- Optimized Tool Paths: CNC programming ensures the most efficient use of raw materials, minimizing scrap.

- Automation: By eliminating manual errors, CNC machining reduces rework and wasted material.

- Long Tool Life: Advanced cooling and tool control mechanisms prolong the life of cutting tools, particularly when working with tough materials like stainless steel.

Example: One of our clients at CNCRUSH required custom stainless steel flanges for an automotive application. By using CNC machining, we reduced material waste by 25%, significantly lowering their production costs.

| Cost Efficiency Factor | Traditional Methods | CNC Machining |

|---|---|---|

| Material Waste | High | Low |

| Labor Costs | High | Minimal |

| Tool Wear and Replacement | Frequent | Optimized |

3. Versatility for Complex Stainless Steel Designs

Stainless steel is often used for intricate parts that demand both strength and precision. Traditional machining methods struggle to achieve these requirements, especially for complex geometries.

CNC Machining’s Edge in Complex Designs:

- Multi-Axis Capabilities: CNC machines with 3, 4, or 5 axes can create intricate geometries, including angled cuts, undercuts, and hollow structures.

- Prototyping and Iteration: CNC machining allows for quick prototyping, enabling clients to test and refine designs before full-scale production.

- Advanced Techniques: CNC milling and turning can handle stainless steel’s toughness without sacrificing accuracy.

CNCRUSH specializes in producing intricate CNC Milled parts and CNC Turned parts for industries like machine building and automation, delivering parts that meet the most demanding specifications.

4. Superior Strength and Durability

Stainless steel parts are valued for their strength and resistance to corrosion, making them ideal for harsh environments. CNC machining preserves these properties by using precise cutting techniques that prevent damage during the manufacturing process.

Strength-Preserving Machining Techniques:

- Minimal Thermal Impact: CNC machines use advanced cooling systems to prevent heat damage, which can compromise stainless steel’s structural integrity.

- Custom Surface Treatments: CNC machining allows for additional treatments, such as passivation or polishing, to enhance durability and corrosion resistance.

- Stress-Free Manufacturing: CNC techniques minimize residual stress in parts, ensuring they perform optimally in demanding applications.

At CNCRUSH, we ensure that every stainless steel component maintains its inherent strength and resilience, making it suitable for critical applications in automotive and industrial machinery.

5. Scalability and Speed for High-Volume Production

For industries requiring high-volume production, CNC machining offers unparalleled scalability and efficiency. Once a design is programmed, CNC machines can produce thousands of identical stainless steel parts with minimal downtime.

Benefits for Large-Scale Production:

- Rapid Setup: CNC programming eliminates the need for time-consuming manual adjustments.

- Continuous Operation: CNC machines can operate 24/7, maximizing output.

- Consistent Quality: High-speed production does not compromise the precision or durability of the parts.

At CNCRUSH, we leverage our advanced facilities to handle both small-batch prototypes and high-volume production runs, ensuring on-time delivery without sacrificing quality.

| Factor | Small-Batch Production | High-Volume Production |

|---|---|---|

| Setup Time | Moderate | Low |

| Per-Unit Cost | Higher | Lower |

| Precision and Consistency | Identical | Identical |

Frequently Asked Questions About CNC Machining for Stainless Steel

Why Is CNC Machining Ideal for Stainless Steel?

CNC machining offers the precision, tool control, and cooling systems necessary to handle stainless steel’s toughness without compromising quality.

What Industries Use CNC Machined Stainless Steel Parts?

Industries such as automotive, aerospace, medical, machine building, and automation rely on CNC machined stainless steel parts for their strength and precision.

How Does CNCRUSH Ensure Quality in Stainless Steel Machining?

At CNCRUSH, we use advanced multi-axis CNC machines, rigorous quality inspections, and material-specific strategies to deliver flawless stainless steel parts.

Why CNCRUSH Is Your Best Choice for CNC Machining Services

When it comes to CNC machining stainless steel parts, CNCRUSH stands out as a global leader. As a trusted China CNC factory, we combine state-of-the-art technology with unmatched expertise to deliver high-quality CNC Milled parts and CNC Turned parts.

Why Choose CNCRUSH?

- Experience: Over 12 years of excellence in CNC machining services.

- Quality Assurance: Rigorous inspections ensure every part meets client specifications.

- Global Reach: Serving industries worldwide with reliable, affordable solutions.

Whether you need custom prototypes or large-scale production, CNCRUSH is your partner for all your stainless steel machining needs. Contact us today to learn how we can transform your manufacturing process with precision and efficiency!