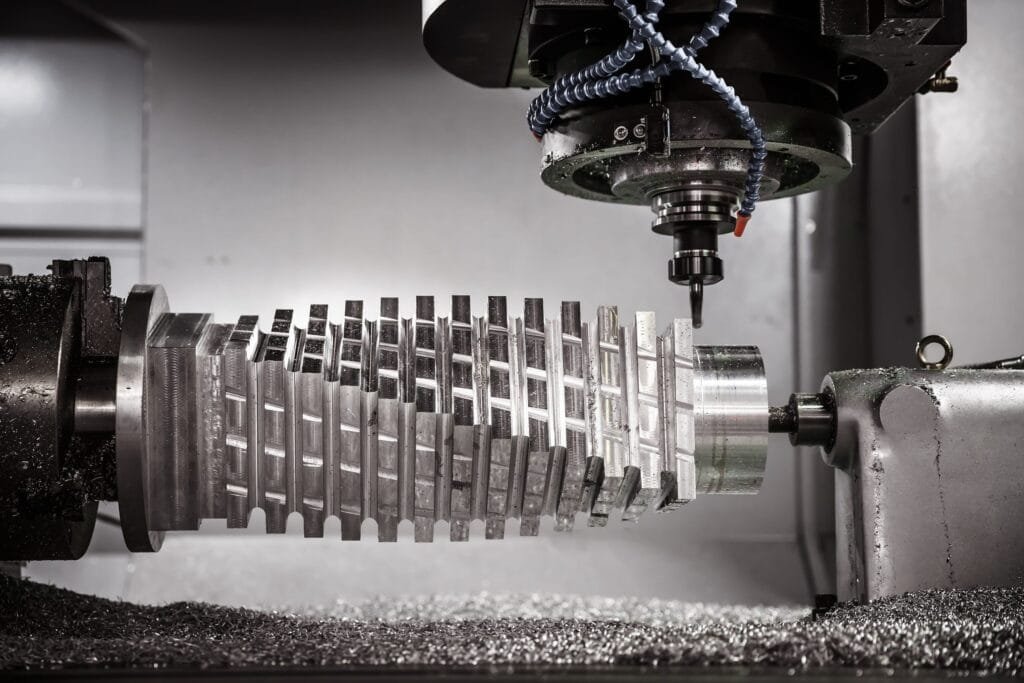

Choosing the right CNC machining approach such as 5-axis CNC machining is essential to ensure your project meets quality, efficiency, and cost requirements. For many applications, understanding the differences between 3-axis and 5-axis CNC machining can reveal which approach will deliver optimal results for complex designs, tight tolerances, and high productivity. Here, we delve into […]

Category Archives: CNCRUSH News

High Speed Machining (HSM) has transformed CNC milling, allowing manufacturers to achieve unparalleled precision, efficiency, and productivity. In this comprehensive guide, we explore high-speed machining techniques and their benefits, guiding you through the process of selecting the best HSM strategies for CNC milling. At CNCRUSH, our CNC machining service has specialized in CNC Milled parts […]

Choosing the best CNC machine for your manufacturing needs requires more than a glance at machine specifications. It’s a detailed process that considers production requirements, long-term budget, materials, software compatibility, and maintenance support. For companies with specific needs like automotive, machine-building, and automation, it’s critical to find a solution tailored to these industries, ensuring the […]

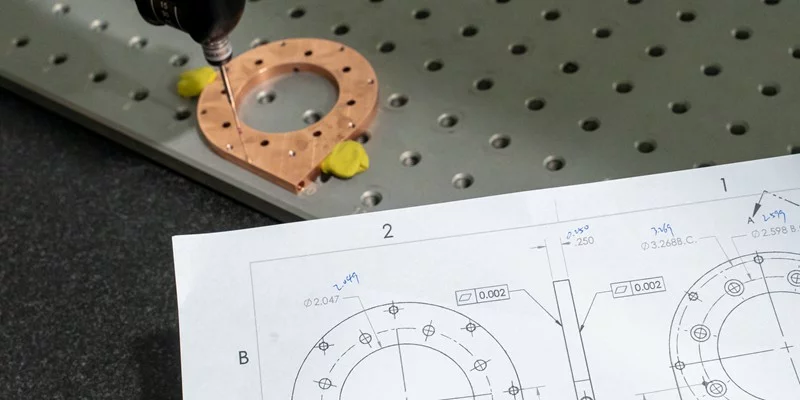

CNC machining tolerances are pivotal in achieving high-quality, functional parts essential for industries like automotive, machine building, and automation. As a top-tier provider, CNCRUSH brings over 12 years of expertise to meet complex tolerance requirements with precision and cost-effectiveness. This article explores the standards, considerations, and strategies in CNC tolerancing to help designers and manufacturers […]

Selecting the right material is crucial for successful CNC machining projects, especially for precision-focused industries like automotive, aerospace, and automation. This comprehensive guide provides an in-depth look into the best materials for CNC machining—namely, aluminum, steel, and plastics. It explores these materials’ unique properties, applications, and key considerations, helping engineers, designers, and project managers make […]

In the evolving landscape of modern manufacturing, CNC machining stands out as one of the most influential technological advancements. The integration of automation, precision, and flexibility into manufacturing has reshaped how industries like automotive, aerospace, medical, and machine building operate. From prototyping to mass production, CNC machining’s transformative power continues to redefine the standards of […]

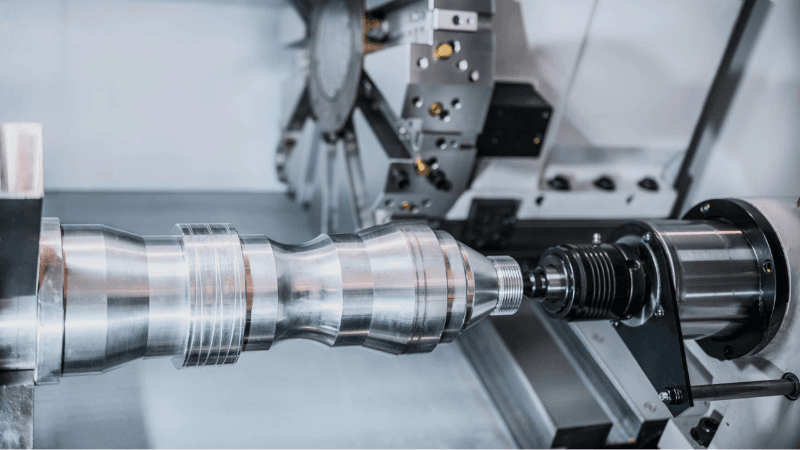

CNC Turning is one of the most pivotal machining processes in modern manufacturing. This article aims to offer an in-depth exploration of CNC turning, with a focus on its mechanics, applications, advantages, and critical differences from other machining methods such as CNC milling. Drawing on material from sources across the CNC machining industry and aligning […]

Custom CNC solutions have become essential in modern industries where precision, efficiency, and repeatability are crucial. As a specialized CNC machining service provider based in China, CNCRUSH has been serving the global market for over 12 years, delivering CNC Milled parts and CNC Turned parts to a variety of industries. The role of CNC machining […]

CNC machining has revolutionized the manufacturing of medical devices by providing the precision, reliability, and flexibility required for producing life-saving tools. With applications spanning orthopedic implants, surgical instruments, diagnostic devices, and more, CNC machining plays a pivotal role in modern healthcare. This article explores the methods, benefits, and challenges of CNC machining in the medical […]

Machined parts are vital to the automotive industry, contributing significantly to vehicle precision, performance, and innovation. CNC machining, known for its accuracy, speed, and adaptability, has transformed the production of automotive parts, ensuring high-quality outputs with minimal waste. From engine components to custom modifications, the role of CNC machining is indispensable in modern automotive manufacturing. […]