Discover how CNC machining services enhance quality in automotive manufacturing. Learn about CNC milled parts, CNC turned parts, and more. Trust CNCRUSH for precision.

Introduction

CNC machining has proven itself to be an indispensable asset in automotive manufacturing. From improving precision to ensuring the longevity and reliability of parts, this technology is at the core of modern automotive production. In this guide, we will explore how CNC machining enhances the quality of automotive components, focusing on CNC milled and turned parts. With over 12 years of experience, CNCRUSH, located in China, provides high-quality CNC machining services to global clients, specializing in aluminum, steel, and plastics machining.

1. Precision Engineering: The Backbone of Automotive Components

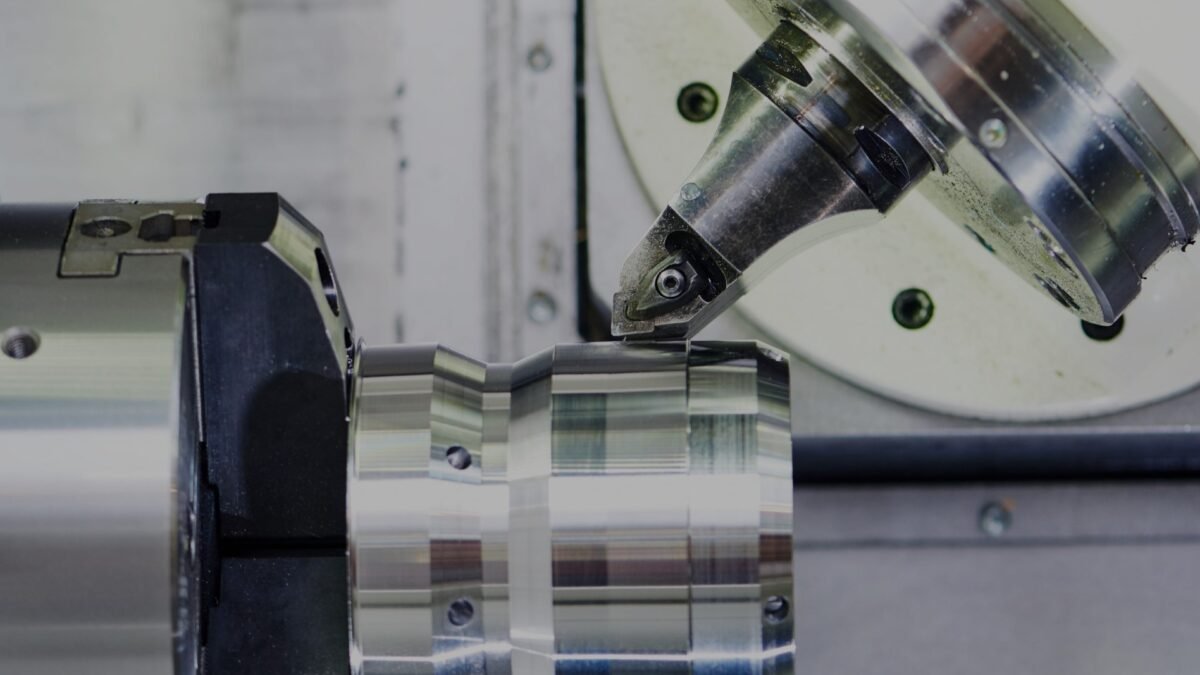

Precision is critical in automotive manufacturing, where even the smallest deviation can lead to catastrophic failures. CNC machining services offer unparalleled precision in crafting CNC milled and turned parts for automotive applications. Unlike traditional machining methods, CNC machining ensures consistency, making it ideal for producing parts that must meet stringent tolerances. This section will explore how CNC milling and turning reduce defects, offering manufacturers the capability to produce highly accurate parts consistently.

2. Increased Speed and Efficiency in Automotive Production

CNC machining accelerates production by automating processes that were once time-consuming and labor-intensive. This section will dive into how CNC machining services increase efficiency, providing a faster turnaround time for automotive parts like engine blocks, transmission components, and suspension parts. The integration of advanced CNC machines also leads to reduced lead times, allowing for quicker market delivery without compromising quality.

3. Cost-Effective Solutions for Automotive Manufacturers

Cost reduction is a major consideration in automotive manufacturing. CNC precision machining services help lower costs through precise material usage, less waste, and reduced labor costs. By eliminating the need for complex setups and tooling changes, CNC machining cuts costs while ensuring that automotive parts, such as gears, shafts, and brackets, are produced to exact specifications. This section will analyze the cost benefits of CNC milled and turned parts.

4. Complex Geometries Made Simple

Automotive parts often require complex shapes and geometries that traditional machining methods struggle to produce. CNC precision machining provides an excellent solution for creating intricate designs with high complexity. Whether it’s producing engine components with deep pockets, multi-angle cuts, or curved surfaces, CNC precision machining allows manufacturers to achieve these complex geometries with ease. We’ll examine how this capability drives innovation in automotive design and production.

5. Material Versatility for Robust Automotive Parts

The variety of materials used in the automotive industry, including aluminum, steel, and plastics, requires machining services capable of handling diverse materials. CNC precision machining services offer versatility in material selection, ensuring high-quality outcomes for automotive parts, including wheels, body panels, and engine parts. This section will highlight how different materials impact the quality and performance of automotive parts and how CNC precision machining ensures the ideal result for each.

6. Automated Quality Control: Ensuring Consistency in Automotive Parts

Consistency and reliability are paramount in automotive parts, and CNC machining services provide the necessary automated quality control systems to meet these demands. We’ll discuss how CNC machines can be equipped with tools like vision systems and probes, which ensure each part is produced to specification. This section will also touch on how CNC milled and turned parts maintain high standards of quality without variation across batches.

7. Reducing Human Error: How CNC Machining Minimizes Mistakes

Human error is a significant risk in manufacturing, leading to costly mistakes. CNC precision machining services, however, reduce the risk of errors significantly. By programming the machine to operate autonomously, manufacturers eliminate the chance of human mistakes during production. This section will explore the impact of reducing human error on automotive quality, emphasizing the role of CNC precision machining in enhancing part consistency.

8. Advanced Finishing Techniques for Automotive Excellence

CNC machining allows for advanced finishing techniques, such as anodizing, painting, or polishing, which are essential for both the aesthetics and durability of automotive parts. This section will explore how post-machining processes add value to CNC milled and turned parts, ensuring they meet the aesthetic standards and functional requirements of the automotive industry.

9. The Role of CNC Machining in Automotive Prototyping

Prototyping is a critical phase in automotive manufacturing, and CNC precision machining services are invaluable during this stage. With rapid prototyping capabilities, CNC machining helps automotive engineers test new designs quickly and efficiently. We’ll delve into how CNC machining aids in the prototyping of automotive components, reducing the time it takes to bring a concept to production.

10. Why Choose CNCRUSH for Your Automotive CNC Machining Needs?

As a leading CNC precision machining provider, CNCRUSH offers unmatched expertise in producing high-precision CNC milled and turned parts. This section will highlight the benefits of working with CNCRUSH, including our extensive experience in automotive manufacturing, our ability to handle diverse materials, and our commitment to delivering cost-effective and high-quality solutions to clients worldwide.

Tables: CNC Machining for Automotive Parts

Table 1: Common Automotive Parts Made with CNC precision Machining

| Part Type | Material Used | CNC Process Used | Functionality |

|---|---|---|---|

| Engine Components | Aluminum, Steel | CNC Turning, CNC Milling | Precision fitting, heat resistance |

| Transmission Parts | Steel | CNC Turning, CNC Milling | Durability, smooth operation |

| Suspension Parts | Steel, Aluminum | CNC Milling, CNC Turning | Strength, performance under stress |

| Brake Components | Steel, Aluminum | CNC Milling, CNC Turning | Safety, precision fitting |

Table 2: Advantages of CNC precision Machining in Automotive Production

| Advantage | Benefit to Automotive Industry |

|---|---|

| Precision and Accuracy | Ensures high tolerance and quality |

| Efficiency and Speed | Reduced production time and costs |

| Material Flexibility | Ability to work with diverse materials |

| Automated Quality Control | Reduces errors and ensures consistency |

| Complex Geometries | Allows for innovative designs |

FAQ Section: CNC Machining in Automotive Manufacturing

Q1: What types of automotive parts can be made using CNC machining?

A: CNC machining can be used for a wide range of automotive parts, including engine components, transmission parts, suspension components, wheels, and brackets. The precision of CNC machining ensures these parts meet strict quality standards.

Q2: How does CNC machining improve the quality of automotive parts?

A: CNC machining improves quality by providing high precision, reducing human error, and offering advanced quality control features. It ensures that parts meet exact specifications and enhances the overall performance and durability of automotive components.

Q3: What are the cost benefits of CNC machining for automotive manufacturers?

A: CNC machining helps reduce costs by minimizing material waste, lowering labor costs, and speeding up production times. It provides a cost-effective solution for producing high-quality parts in the automotive industry.

Conclusion

CNC machining has revolutionized the automotive manufacturing industry, offering significant improvements in quality, speed, and cost-efficiency. From precision engineering to advanced material capabilities, CNC machining services like those offered by CNCRUSH are integral to the creation of high-quality automotive parts. With over 12 years of experience, CNCRUSH is your trusted partner for CNC milled and turned parts, delivering precision and reliability in every project.

For more information on our CNC machining services, visit CNCRUSH today.