For businesses seeking high-quality CNC machining services, particularly in metal manufacturing, CNCRUSH offers over 12 years of expertise. Located in China, CNCRUSH specializes in CNC Milled and CNC Turned parts for global clients, ensuring top-notch quality and precision in every piece.

Summary of Articles Analyzed

Several articles have been reviewed to help us understand the importance of accuracy and precision in CNC machining. These sources emphasize that both accuracy (the ability to produce parts that are close to a target dimension) and precision (the ability to consistently replicate these dimensions) are critical in achieving high-quality parts. From machine setup and tool selection to material properties, many factors affect how precise and accurate the final product will be. In addition to enhancing part quality, these articles stress the role of CNC technology in boosting production times, efficiency, and cost-effectiveness.

10 Key Areas of CNC Machining for Enhanced Accuracy and Precision

1. The Basics of CNC Machining: What Drives Accuracy and Precision?

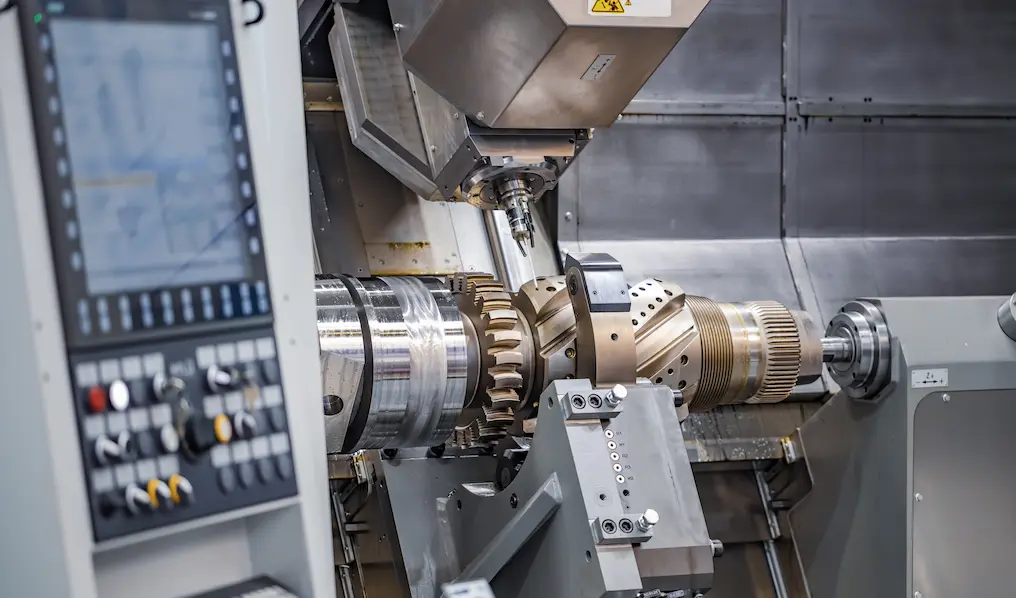

CNC machining involves a variety of processes where computer-controlled machines remove material from a workpiece to create the desired shape. For CNC Milled and CNC Turned parts, the precision is dictated by the programming, tooling, machine stability, and material properties.

In CNC milling, accuracy is achieved through carefully calibrated cutting tools and precise machine movements along multiple axes. CNC turning, on the other hand, achieves accuracy by rotating the workpiece while a cutting tool removes material. Both processes ensure that the dimensions of the part are replicated consistently, even in large production runs.

Key Factors Affecting Precision:

- Machine setup and calibration

- Tool selection and maintenance

- Material quality

- Machine rigidity and stability

2. Importance of CNC Milled Parts in Automotive and Machine Building

CNC Milled parts play a crucial role in industries like automotive and machine building, where high precision is needed to ensure parts fit together correctly. The automotive industry relies on CNC Milled components for everything from engine blocks to intricate suspension parts. Similarly, in machine building, CNC Milled parts are used for custom jigs, fixtures, and machinery components.

By employing CNC Milled technology, manufacturers can achieve part tolerances of +/- 0.005mm, ensuring that each part aligns perfectly during assembly.

3. How CNC Turned Parts Offer Superior Precision for Automation Components

CNC Turned parts are essential in the automation sector, where high-precision components like gears, shafts, and actuators must perform consistently in harsh environments. CNC turning ensures that the workpiece is held securely while the cutting tool removes material to produce intricate, dimensionally precise features.

One of the key advantages of CNC Turning is its ability to maintain concentricity, making it ideal for parts that require uniformity and tight tolerances across cylindrical components.

4. Achieving Precision in CNC Machining: The Role of Material Selection

Material properties play a significant role in achieving precision in CNC machining. For example, aluminum, steel, and brass are commonly used materials in CNC Machining because of their stability and ease of machining.

- Aluminum: Lightweight and highly machinable, ideal for high-precision components.

- Steel: Offers strength and durability, perfect for parts that must withstand wear.

- Brass: Excellent for parts requiring electrical conductivity and corrosion resistance.

Choosing the right material ensures that the part retains its shape during machining and under real-world conditions, maintaining both accuracy and durability.

5. The Crucial Role of CNC Machining for Metal Parts in the Manufacturing Process

Metal parts, from automotive engine components to industrial machine parts, rely on CNC machining to achieve consistent precision. Unlike traditional machining methods, CNC technology provides automated, repeatable processes that significantly improve the consistency of metal parts.

For example, when producing automotive components, the need for high tolerance and precise fitting is critical. CNC Machining services, especially for metal parts, help reduce the potential for defects while lowering production costs by streamlining the process.

6. Enhancing Production Speed Without Sacrificing Quality in CNC Machining

While accuracy and precision are paramount, CNC machining also offers the advantage of increasing production speed. In industries like automotive manufacturing, fast turnaround times are essential. CNC machining’s ability to work on multiple axes simultaneously reduces the need for lengthy setup times and ensures that multiple parts can be machined in less time.

Moreover, CNC machines can run continuously with minimal downtime, enabling manufacturers to meet tight deadlines without compromising quality.

7. Fine-Tuning CNC Programming for Even Greater Precision

Programming plays a vital role in ensuring that CNC machines achieve maximum precision. Software like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) help design and optimize machining strategies, ensuring the part is produced with the required tolerances.

Fine-tuning these programs enables precise control over toolpaths, speeds, feeds, and depth of cuts, ensuring a high-quality finish and dimensional accuracy in the final part.

8. The Benefits of Using Advanced CNC Machines for Part Accuracy

Modern CNC machines are equipped with advanced features such as automatic tool changers, probes, and integrated inspection systems. These features allow for real-time monitoring of part dimensions during the machining process, correcting any variations immediately to prevent defects.

Additionally, high-precision machines, such as 5-axis CNC mills, can produce complex geometries with exceptional accuracy, making them ideal for industries requiring highly intricate parts.

9. The Significance of Post-Processing for CNC Milled and Turned Parts

Once a part is machined, it may undergo post-processing operations such as polishing, heat treatment, and surface finishing to further enhance accuracy. These processes refine the part’s surface and remove any residual stresses, ensuring that the part maintains its dimensional integrity.

In sectors like aerospace and automotive, post-processing is critical to ensure that the parts meet stringent quality and performance standards.

10. CNC Machining Services at CNCRUSH: Your Solution for Precision and Accuracy

For over 12 years, CNCRUSH has been providing high-precision CNC machining services, specializing in CNC Milled and CNC Turned parts for industries like automotive, machine building, and automation. As a China-based CNC factory, we offer a cost-effective solution for manufacturers seeking high-quality, custom CNC parts.

Our advanced CNC machining equipment and experienced technicians ensure that every part is made to precise specifications. Whether you’re in need of aluminum, steel, or plastic components, CNCRUSH can deliver the parts you need with accuracy and precision that you can rely on.

Tables: Analysis of CNC Machining Precision in Various Industries

Table 1: Accuracy Tolerances for CNC Milled and CNC Turned Parts

| Process | Tolerance Range | Industry Application | Material Example |

|---|---|---|---|

| CNC Milling | ±0.005mm to ±0.02mm | Automotive, Aerospace, Machine Building | Aluminum, Steel |

| CNC Turning | ±0.005mm to ±0.01mm | Automation, Robotics, Medical Devices | Brass, Stainless Steel |

Table 2: Benefits of CNC Machining in Various Industries

| Industry | CNC Machining Benefits | Key Parts Manufactured |

|---|---|---|

| Automotive | High precision, fast production | Engine blocks, transmission components |

| Machine Building | Customized parts, high quality | Gear components, jigs, fixtures |

| Automation | Consistent quality, efficient | Actuators, gears, robotic arms |

Frequently Asked Questions (FAQ)

Q: What is the difference between CNC Milled and CNC Turned parts? A: CNC Milled parts are produced by removing material with rotary tools from a stationary part, while CNC Turned parts are created by rotating the workpiece and cutting it with stationary tools. Both methods offer high precision, but they are suited to different geometries and applications.

Q: How does CNC Machining improve accuracy in the automotive industry? A: CNC machining ensures that each automotive part, such as engine blocks and suspension components, is made with tight tolerances and uniformity. The precision of CNC machining reduces defects, improves fitment, and ensures that parts perform reliably in high-performance environments.

Conclusion

CNC machining has revolutionized the manufacturing industry by providing unmatched precision and accuracy. Whether it’s CNC Milled parts or CNC Turned parts, the ability to consistently produce high-quality components is essential for industries like automotive, machine building, and automation. With CNCRUSH’s 12 years of experience, our CNC machining services can provide the precision and reliability your business needs to stay ahead. Visit CNCRUSH to learn more about how we can support your manufacturing needs and enhance your product quality.