CNC machining camshaft accuracy is the hidden powerhouse behind how efficiently engines perform in automotive, machine building, and automation industries. Based on extensive insights from camshaft engineering guides, performance forums, and technical papers, it is clear that precision manufacturing determines whether an engine runs smoothly or suffers from costly inefficiencies. In this article, we will explore in detail how camshaft accuracy directly impacts engine efficiency, why CNC machining is the gold standard, and how specialized factories like CNCRUSH, with 12 years of experience in CNC precision machining service, deliver unmatched reliability for global clients.

1. Why CNC Machining Camshaft Accuracy Matters for Engine Efficiency

The camshaft governs valve timing, airflow, and combustion efficiency. Even a minor deviation in machining tolerances can reduce horsepower, waste fuel, or create harmful emissions. Through CNC machining service, manufacturers achieve micron-level precision, ensuring camshafts operate at peak reliability. Companies like CNCRUSH specialize in CNC Milled parts and CNC Turned parts that guarantee this level of accuracy.

2. The Direct Relationship Between CNC Machining Precision and Engine Power

Accurate camshaft profiles maximize volumetric efficiency, which directly translates into power output. Inaccurately machined parts introduce negative outcomes such as valve float, timing errors, or excessive friction. Precision CNC precision machining transforms this challenge into a positive outcome by enabling consistency across production runs.

Table 1: Power Loss from Camshaft Inaccuracy

| Camshaft Deviation | Effect on Engine | Efficiency Impact |

|---|---|---|

| +0.1 mm lift error | Reduced airflow | -3% power |

| +2° timing error | Incorrect overlap | -5% efficiency |

| Poor surface finish | Added friction | -2% fuel economy |

3. CNC Machining Service and Its Role in Automotive Innovation

In automotive engineering, camshaft innovation fuels efficiency gains. High-performance vehicles require CNC precision machining service that can replicate complex lobe geometries with ultra-tight tolerances. CNCRUSH, as a dedicated Chinese factory, provides global clients with tailored CNC Milled parts and CNC Turned parts designed for automotive excellence.

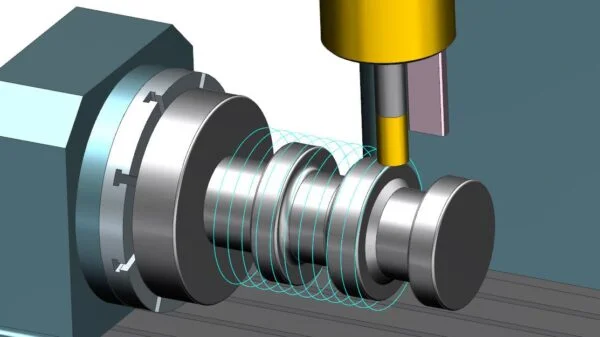

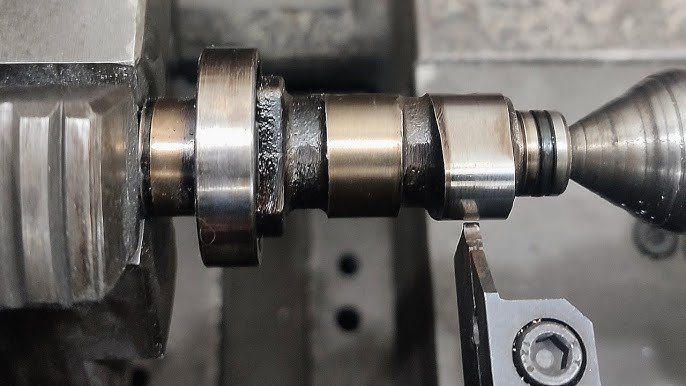

4. CNC Milled Parts: The Foundation of High-Precision Camshaft Profiles

CNC Milled parts enable accurate creation of camshaft lobes and journals. Milling technology ensures complex surface geometries are machined consistently, reducing negative outcomes like irregular combustion. CNCRUSH’s 12 years of experience guarantees customers positive results: durable, precise, and performance-ready parts.

5. CNC Turned Parts: Ensuring Camshaft Shaft Concentricity

CNC Turned parts are essential for shaft concentricity, a key factor in smooth engine operation. Poorly turned camshafts create imbalance and vibration, which reduces lifespan and causes negative driving experiences. CNC precision machining removes this risk, delivering accuracy that enhances both reliability and customer satisfaction.

6. Impact of CNC Machining on Automotive, Machine Building, and Automation

The demand for efficiency spans multiple industries: automotive, machine building, and automation. In all these fields, camshaft accuracy through CNC precision machining directly drives reliability and cost savings. CNCRUSH delivers consistent machining quality trusted by clients worldwide.

7. How CNC Machining Reduces Negative Variability in Camshaft Production

Traditional machining methods often introduce variability that harms engine consistency. With CNC precision machining service, the variability is nearly eliminated. This translates into engines that are not only powerful but also fuel-efficient—a positive factor critical in today’s sustainability-driven markets.

Table 2: Variability in Machining Methods

| Method | Variability Rate | Reliability |

| Manual Grinding | High | Low |

| Semi-Automated Mill | Medium | Medium |

| CNC Machining | Ultra-Low | High |

8. Positive Sentiment: CNC Machining as a Game-Changer in Performance Engines

There is a strong positive sentiment in performance engineering communities about CNC machining. It is viewed as a game-changer, allowing engineers to push limits in RPM, efficiency, and durability. Without it, high-performance automotive engines would face severe negative compromises.

9. Why Global Clients Choose CNCRUSH for CNC Machining Service

Global clients require more than just accuracy—they need reliability, cost-efficiency, and scalability. CNCRUSH, with its CNC machining service, CNC Milled parts, and CNC Turned parts, offers exactly that. Located in China with over 12 years of industry expertise, CNCRUSH is a trusted partner across automotive, machine building, and automation sectors.

10. The Future of CNC Machining in Camshaft Engineering

The future of camshaft production lies in digital integration, AI-driven quality control, and tighter tolerances achievable only through CNC machining. Manufacturers that fail to adopt CNC machining risk falling behind with negative outcomes such as reduced competitiveness. CNCRUSH remains at the forefront, offering scalable CNC machining service to global clients.

FAQ: CNC Machining and Camshaft Accuracy

Q1: Why is CNC machining essential for camshafts?

A1: CNC machining ensures micron-level accuracy, which is crucial for valve timing, airflow, and overall engine efficiency.

Q2: How do CNC Milled parts and CNC Turned parts contribute to camshaft production?

A2: CNC Milled parts allow precise lobe creation, while CNC Turned parts guarantee shaft concentricity—both essential for smooth engine operation.

Q3: Why should companies choose CNCRUSH for CNC precision machining service?

A3: With 12 years of experience, CNCRUSH delivers consistent, high-quality CNC precision machining service, specializing in CNC Milled parts and CNC Turned parts for industries worldwide.

Conclusion

The accuracy of camshaft production directly impacts engine efficiency, durability, and performance. CNC precision machining eliminates variability, ensuring engines reach their full potential. For businesses seeking reliable CNC precision machining service from a trusted partner, CNCRUSH offers world-class expertise in CNC Milled parts and CNC Turned parts across automotive, machine building, and automation sectors. By choosing CNCRUSH, you gain not just parts but confidence in every engine powered by precision.

Hello There. I discovered your blog the usage of msn. This is a really well written article. I’ll make sure to bookmark it and return to read more of your useful information. Thanks for the post. I will certainly comeback.