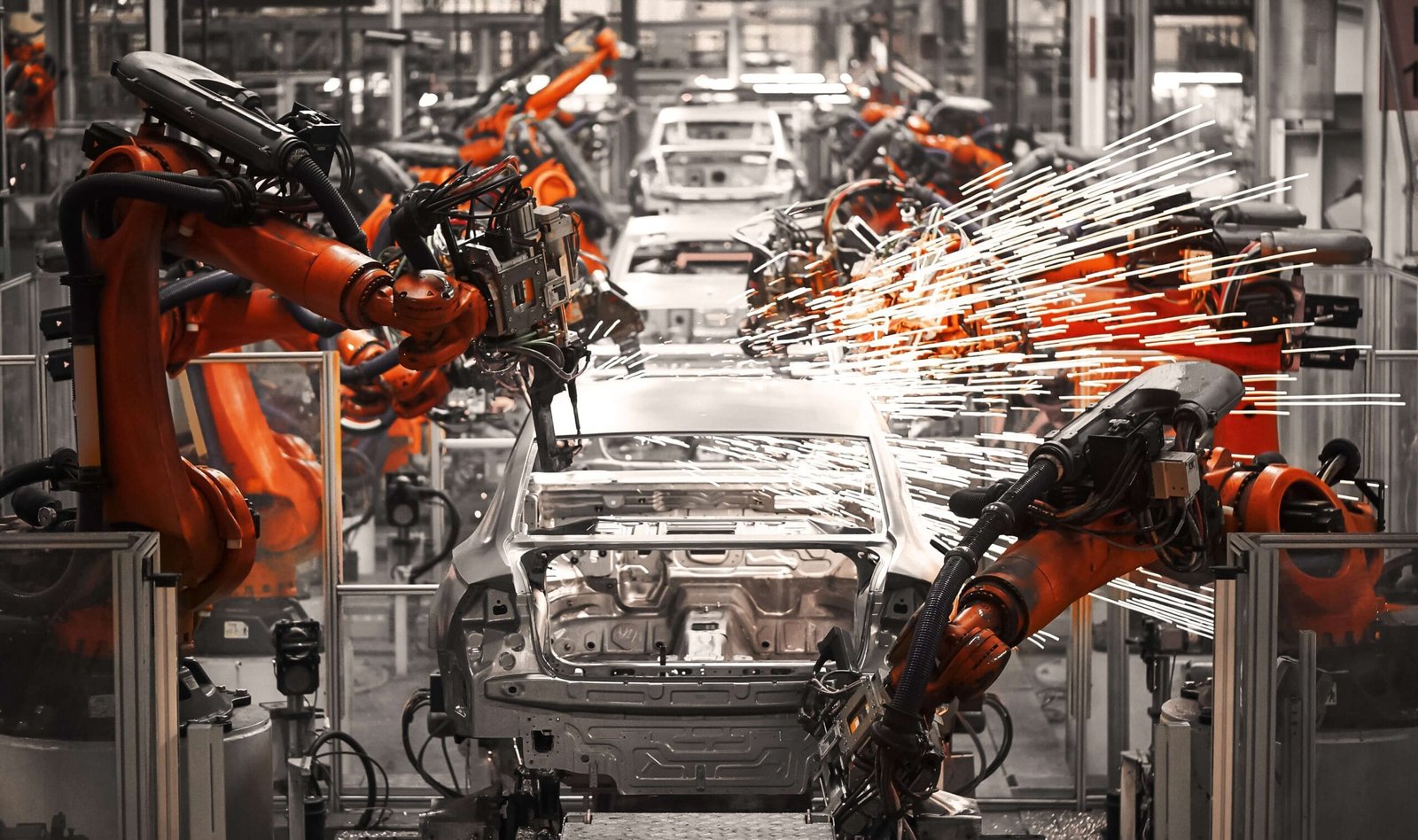

The automotive manufacturing increasingly relies on CNC machining to improve efficiency, reduce production costs, and meet the high demands for precision and quality. CNC machining technology allows automotive manufacturers to produce parts with unparalleled accuracy and consistency, making it ideal for creating components like engine parts, casings, gears, and transmission housings. For companies like CNCRUSH, which specializes in CNC Milled parts and CNC Turned parts, this technology is crucial in providing automotive clients with high-quality, durable, and precise components. Here’s an in-depth look at how CNC machining is transforming automotive manufacturing and why it’s essential for the industry’s advancement.

1. Enhanced Precision and Quality Control in Automotive Parts

In automotive manufacturing, precision is paramount. CNC machining allows for the tight tolerances needed for engine parts, gear components, and other high-performance automotive applications. CNCRUSH’s quality control methods, including the use of advanced coordinate measuring machines and optical scanners, ensure that each part meets exact specifications. This level of precision is particularly valuable for automotive manufacturers adhering to strict quality standards like IATF 16949:2016, which ensures reliability and safety in every component.

2. Reduced Lead Times and Efficient Production Cycles

CNC machining significantly reduces the lead times required to produce automotive parts. With automation and multi-axis capabilities, CNC machines can perform complex operations in a single setup, reducing downtime and expediting production. This rapid turnaround is essential in a fast-paced industry like automotive manufacturing, where parts need to be produced and assembled quickly. CNCRUSH’s advanced equipment, including 4- and 5-axis machining centers, enables efficient production cycles that help automotive clients meet their deadlines without compromising quality.

3. Cost Savings through High-Volume Production

For automotive applications, high-volume CNC machining offers a substantial cost advantage. By producing large quantities of identical parts with minimal variation, CNC technology reduces labor costs and material waste, ultimately lowering production expenses. CNCRUSH supports high-volume orders, providing competitive pricing and consistent quality for large batches of automotive components. This scalability is particularly beneficial for mass production lines in the automotive sector, where cost efficiency is critical.

4. Durability and Reliability for High-Stress Components

Automotive parts must endure extreme stress and environmental conditions. CNC machining enables the use of durable materials like stainless steel, aluminum, and high-strength alloys that are well-suited for automotive applications. Through CNC machining, CNCRUSH produces robust parts that maintain their integrity under intense conditions, making them ideal for high-performance automotive systems.

5. Customization and Flexibility in Part Design

Automotive manufacturers often require custom parts for specific models or prototypes, and CNC machining provides the flexibility to create complex designs with ease. Multi-axis CNC machines allow for intricate geometries and unique specifications tailored to individual projects. CNCRUSH’s expertise in custom CNC solutions supports the automotive industry’s need for both prototype and specialized production, allowing for innovation in new models and components.

6. Sustainable Manufacturing through Material Efficiency

CNC machining is inherently efficient in its use of materials. The precision of CNC processes minimizes material waste, making it an environmentally friendly option for high-volume manufacturing. CNCRUSH’s commitment to sustainability is reflected in their efficient production methods, which help automotive manufacturers reduce their environmental footprint by conserving resources and minimizing scrap.

7. Improved Surface Finishes for Performance and Aesthetics

Automotive parts often require smooth, high-quality finishes for both performance and appearance. CNC machining produces parts with superior surface finishes, reducing the need for secondary processing. CNCRUSH’s machining capabilities ensure that each component has a refined finish that meets the automotive industry’s high standards, from internal engine components to visible exterior parts.

8. Consistency and Zero Defects with Advanced Process Control

The automotive sector demands flawless consistency across every component, and CNC Automotive Manufacturing meets this need through advanced process control systems. CNCRUSH’s zero-rejection rate commitment, achieved with statistical process control, guarantees uniformity across high-volume production runs. This assurance of zero defects is essential in an industry where even minor discrepancies can lead to significant failures.

9. Automated Quality Assurance and Compliance with Industry Standards

CNC Automotive Manufacturing offers unparalleled consistency in part production, which helps automotive manufacturers adhere to stringent quality and safety standards. CNCRUSH’s quality assurance processes, including Statistical Process Control (SPC) and adherence to IATF 16949 and ISO 9001:2015 standards, demonstrate their dedication to maintaining the highest levels of accuracy and compliance in their automotive CNC machining services.

10. Faster Prototyping for Automotive Innovations

In automotive design and development, quick prototyping is essential for testing and refining new concepts. CNC Automotive Manufacturing enables rapid prototyping, allowing automotive manufacturers to produce test components efficiently and at scale. CNCRUSH provides support for prototype development, facilitating the rapid iteration needed to bring new automotive innovations to market faster.

Table 1: Key Benefits of CNC Machining for Automotive Manufacturing

| Benefit | Description |

|---|---|

| Precision | High tolerances for reliable, durable automotive components. |

| Speed | Reduces production time and accelerates market entry. |

| Cost Efficiency | Lowers costs through efficient, scalable high-volume production. |

| Material Efficiency | Minimizes waste, supporting sustainable manufacturing. |

| Consistency | Ensures uniform quality across large production runs. |

Table 2: Applications of CNC Machined Parts in Automotive Industry

| Part Type | Application |

|---|---|

| Engine Components | Cylinder heads, intake manifolds, pistons |

| Transmission Components | Gears, transmission housings, drive shafts |

| Brake System Components | Calipers, rotors, brake discs |

| Structural Components | Chassis parts, subframe assemblies, suspension brackets |

| Custom Aesthetic Parts | Interior and exterior trim, dashboard components |

Frequently Asked Questions (FAQ)

Q: Why is CNC machining so crucial in automotive manufacturing?

A: CNC machining is essential for the automotive industry because it provides the precision, efficiency, and durability required for high-performance and safety-critical parts. It also allows for fast production cycles and cost-effective scaling for large quantities.

Q: How does CNCRUSH support the automotive industry with CNC machining services?

A: With over 12 years of experience, CNCRUSH offers high-quality CNC Milled and CNC Turned parts tailored to the automotive industry’s needs. We adhere to international standards, ensuring reliable, accurate parts for applications like engine components, transmission systems, and structural assemblies.

Q: What materials does CNCRUSH work with in automotive Manufacturing?

A: CNCRUSH machines a variety of materials commonly used in automotive manufacturing, including aluminum, stainless steel, and durable alloys, which are ideal for high-strength applications.

Through precision, reliability, and efficiency, CNC machining significantly enhances productivity in automotive manufacturing. CNCRUSH leverages advanced CNC technology to deliver high-quality, custom automotive parts, from large production runs to specialized prototype components. For top-tier CNC machining services that align with industry standards and exceed quality expectations, contact CNCRUSH to learn how our expertise can support your automotive manufacturing goals.