In today’s fast-paced manufacturing landscape, CNC machining has emerged as a cornerstone of modern metalworking, delivering unmatched productivity, precision, and scalability. For over 12 years, CNCRUSH, a leading CNC machining service provider based in China, has specialized in high-quality CNC Milled parts and CNC Turned parts for industries like automotive, machine building, and automation. This article explores 10 key ways CNC machining revolutionizes metalworking productivity, demonstrating why it’s essential for manufacturers seeking efficiency and quality.

1. What is CNC Machining and Why It Matters for Productivity

CNC (Computer Numerical Control) machining refers to the use of computer-controlled tools to manufacture precision components. Unlike manual methods, CNC machining enables automated, repeatable, and highly accurate production processes, minimizing human error.

At CNCRUSH, we harness the power of CNC machining to deliver customized solutions for industries like automotive and automation, where precision is non-negotiable. With CNC machining, we streamline processes to ensure faster lead times and superior quality.

Benefits Overview:

| Key Feature | How It Enhances Productivity |

|---|---|

| Automation | Eliminates manual intervention, speeding up production. |

| Consistent Precision | Reduces errors, improving yield rates. |

| Versatility | Supports multiple materials (aluminum, steel, plastics). |

2. Streamlined Production with CNC Milled Parts

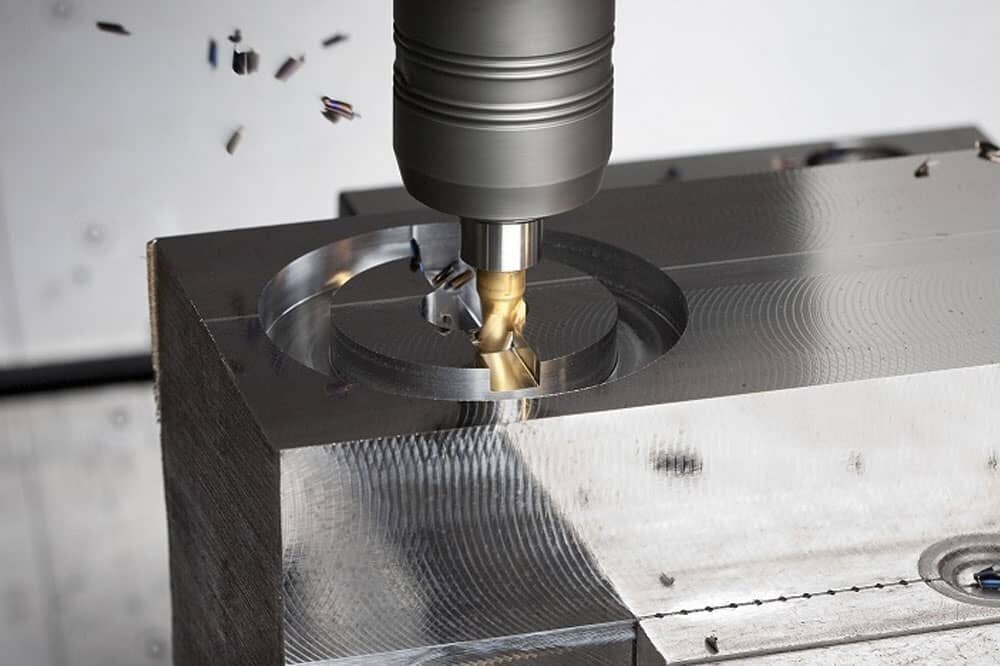

CNC milling is a transformative process where rotary cutters remove material from a workpiece to create complex shapes. This method is ideal for producing intricate designs in metalworking and plastic machining, making it indispensable for industries requiring tight tolerances.

At CNCRUSH, our CNC milling capabilities are tailored for projects demanding high-precision components, from automotive parts to industrial automation systems.

Why CNC Milled Parts Are Essential:

- Achieve complex geometries that are impossible with traditional methods.

- Guarantee consistent quality across high-volume production runs.

- Reduce lead times with efficient programming and automation.

3. The Advantages of CNC Turned Parts in Automation

CNC turning involves rotating a workpiece while a cutting tool shapes it, producing cylindrical components with remarkable accuracy. This process is crucial for industries like machine building and automation, where precision is key to operational efficiency.

At CNCRUSH, our CNC Turned parts are crafted to meet the exacting standards of global clients, providing solutions for applications such as shafts, bushings, and fasteners.

Highlights of CNC Turned Parts:

| Benefit | Impact on Productivity |

|---|---|

| Precision Engineering | Ensures tight tolerances for assembly. |

| Cost Efficiency | Reduces material wastage. |

| High-Speed Production | Meets urgent deadlines effortlessly. |

4. CNC Machining for Custom and Complex Designs

Custom CNC machining allows manufacturers to tackle projects with unique specifications, such as prototypes or bespoke parts. By leveraging advanced CNC technology, we produce components that align perfectly with our clients’ requirements.

Why Custom CNC Solutions Are Game-Changing:

- Provide flexibility for small-batch or high-mix production.

- Enable rapid prototyping for faster product development.

- Ensure compatibility with advanced CAD designs.

5. Enhancing Quality and Precision with CNC Machining

The hallmark of CNC machining is its ability to produce parts with impeccable precision, often within tolerances of ±0.001 inches. This level of accuracy is crucial for industries like automotive and machine building, where even minor discrepancies can lead to operational failures.

At CNCRUSH, we take pride in our meticulous quality control systems, ensuring every component meets or exceeds client expectations.

6. CNC Machining for Diverse Materials: Metal and Plastic

From CNC machining aluminum to CNC plastic machining, the versatility of CNC systems is unparalleled. These machines handle a wide range of materials, making them ideal for diverse applications.

| Material | Applications | Advantages |

|---|---|---|

| Aluminum | Aerospace, automotive, electronics | Lightweight, corrosion-resistant |

| Steel | Heavy machinery, construction | Strong, durable |

| Plastics | Medical, electronics, consumer products | Lightweight, versatile |

7. Reduced Lead Times with CNC Machining Services

One of the biggest productivity gains from CNC machining is the ability to deliver faster turnaround times. Unlike manual processes, CNC machines operate continuously, reducing production bottlenecks.

At CNCRUSH, we use state-of-the-art CNC equipment to fulfill orders quickly without compromising quality.

8. CNC Machining in Automotive Applications

The automotive industry demands precision and efficiency at scale. CNC machining plays a pivotal role in manufacturing critical components like engine parts, brackets, and housings.

Our experience at CNCRUSH has made us a trusted partner for automotive manufacturers worldwide. With our advanced CNC milling and turning capabilities, we meet the industry’s stringent quality standards.

9. Cost-Effectiveness Through Material Optimization

CNC machining minimizes material waste by employing efficient cutting strategies and simulations. This cost-saving benefit is particularly significant for expensive materials like titanium and brass.

At CNCRUSH, we emphasize sustainable manufacturing practices by optimizing material usage, delivering cost-effective solutions to our clients.

10. Future Trends in CNC Machining for Metalworking

As CNC technology evolves, innovations like AI-driven programming and 5-axis machining are revolutionizing the metalworking industry. These advancements further enhance productivity by enabling greater automation and complexity in designs.

At CNCRUSH, we stay ahead of these trends, constantly upgrading our processes to ensure our clients receive the most advanced CNC machining services available.

FAQs About CNC Machining Services

Q1: What is the difference between CNC milling and turning?

A1: CNC milling involves rotary cutters to remove material, ideal for complex shapes, while CNC turning uses a lathe to produce cylindrical parts.

Q2: Why should I choose CNCRUSH for CNC machining services?

A2: With over 12 years of experience, CNCRUSH delivers high-quality CNC Milled parts and CNC Turned parts for industries like automotive and automation.

Q3: What materials do you work with?

A3: We specialize in CNC machining aluminum, steel, brass, and plastics, catering to diverse industry needs.

Why Choose CNCRUSH for CNC Machining Services

As a trusted China CNC factory, CNCRUSH combines cutting-edge technology with deep expertise to deliver precision-engineered components. Whether you need custom CNC parts for prototypes or large-scale production, our focus on quality, affordability, and efficiency ensures your success.

For unparalleled CNC machining solutions tailored to your needs, contact CNCRUSH today!

Elevate Your Manufacturing with CNCRUSH

Choosing the right partner for your CNC machining needs can significantly impact your project’s success. At CNCRUSH, we don’t just deliver parts—we provide solutions. Our commitment to excellence, backed by state-of-the-art technology and over a decade of experience, allows us to meet the most demanding requirements for CNC Milled parts and CNC Turned parts in industries like automotive, automation, and machine building. Whether you’re seeking custom CNC solutions, high-volume production, or rapid prototyping, our expertise ensures every component is crafted with precision, efficiency, and affordability. Let CNCRUSH transform your manufacturing process—because your success is our priority.