CNC Machining represents the pinnacle of modern manufacturing, offering the capability to craft intricate designs with unparalleled precision. Whether for automotive, machine building, or automation industries, the demand for accuracy has never been higher. This article examines the critical role precision plays in CNC machining services, highlighting its importance in creating reliable, high-quality components. By choosing CNCRUSH, clients can leverage over 12 years of experience in producing exceptional CNC Milled parts and CNC Turned parts for various applications.

1. The Role of CNC Machining Services in Complex Geometries

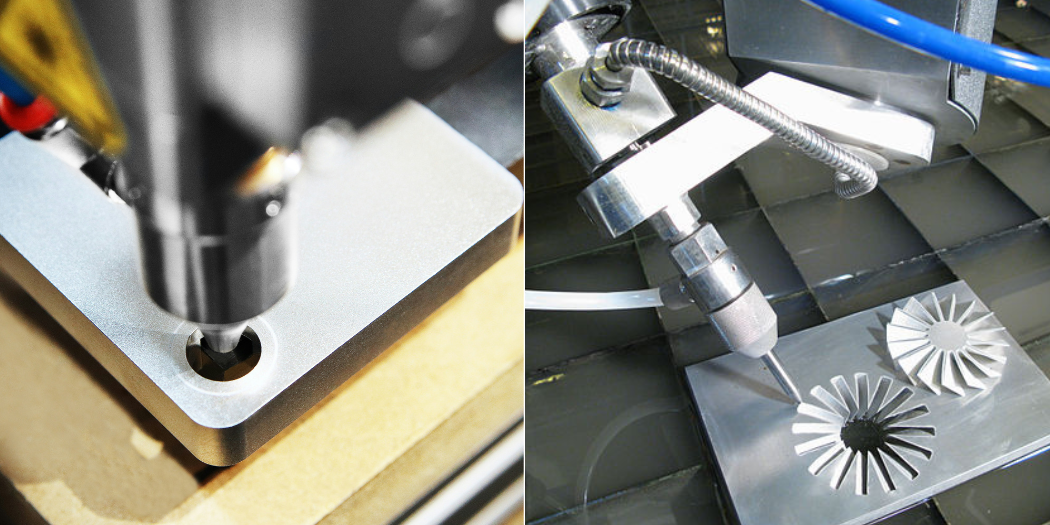

Precision CNC machining is indispensable when dealing with complex geometries. Unlike traditional methods, which may falter with intricate designs, CNC machines deliver unparalleled accuracy by using computer-controlled operations. Components with undercuts, cavities, and multi-angled surfaces are produced efficiently, meeting even the most stringent tolerances.

Key Insights:

- Multi-Axis Flexibility: Advanced 4-axis and 5-axis CNC machines are capable of machining highly detailed features in a single setup, reducing errors caused by part repositioning.

- Complex Part Production: Products like impellers, engine blocks, and aerospace turbine blades depend on CNC machining for their intricate designs.

Case Study:

At CNCRUSH, our commitment to CNC machining services is evident in our ability to handle demanding projects. By employing sophisticated machinery, we help clients bring even the most challenging designs to life.

2. Challenges in Achieving Precision for Complex Parts

Precision in CNC machining is not without its challenges. Factors such as material properties, tool wear, and thermal deformation can compromise accuracy. These issues become more pronounced when machining components with intricate geometries or tight tolerances.

Addressing the Challenges:

- Tool Wear: Regular tool replacement and inspection are crucial for maintaining cutting accuracy.

- Thermal Deformation: Advanced cooling systems help minimize distortion caused by heat generated during machining.

- Vibration Control: Precision is enhanced by using stable fixtures and dampening techniques to reduce machine vibrations.

At CNCRUSH, we mitigate these challenges through rigorous quality control and advanced process management, ensuring consistent results for CNC Milled parts and CNC Turned parts.

3. Material Considerations in Precision CNC Machining

Selecting the right material is critical for precision machining. Each material presents unique challenges, from machinability to thermal expansion. Understanding these factors allows manufacturers to optimize their processes.

| Material | Machinability | Applications |

|---|---|---|

| Aluminum | High | Lightweight automotive components, aerospace parts |

| Steel | Medium | Gears, shafts, and machine components |

| Brass | High | Electrical connectors, decorative fittings |

| Plastics | Medium | Custom enclosures, lightweight automation parts |

Material-Specific Strategies:

- Aluminum: Use high-speed tools to prevent material tearing and achieve smooth finishes.

- Steel: Employ coolant and slow feed rates to manage heat and tool wear.

- Brass: Leverage sharp tools to achieve clean cuts without burrs.

CNCRUSH specializes in machining a wide range of materials, offering clients tailored solutions for automotive, machine building, and automation applications.

4. Multi-Axis Machining: A Game-Changer for Complex Designs

Multi-axis CNC machining, particularly 5-axis machining, revolutionizes the production of complex geometries. By allowing simultaneous movement along multiple axes, it eliminates the need for multiple setups, ensuring precision and efficiency.

Benefits of Multi-Axis Machining:

- Improved Accuracy: Reduced need for manual repositioning minimizes human error.

- Shorter Lead Times: Components are completed faster, ideal for industries with tight deadlines.

Applications:

- Aerospace turbine blades with intricate curves

- Automotive parts like suspension components

At CNCRUSH, our state-of-the-art 5-axis machines enable us to meet even the most demanding project requirements, solidifying our reputation for precision in CNC machining services.

5. Importance of CNC Milled Parts in Automation

In automation systems, precision is paramount. CNC Milled parts such as housings, brackets, and fixtures ensure the seamless integration of mechanical and electronic components.

Key Features:

- Dimensional Accuracy: Ensures that parts fit perfectly, reducing assembly errors.

- Durability: Materials like steel and aluminum provide the strength required for long-term reliability.

Example:

At CNCRUSH, we deliver CNC Milled parts that meet the exact specifications of automation clients, ensuring operational efficiency and product longevity.

6. CNC Turned Parts for High-Precision Applications

CNC Turned parts, often cylindrical, are essential in various industries. These include automotive applications where components like shafts and bushings must meet tight tolerances to ensure performance.

Unique Benefits:

- Smooth Surfaces: Essential for components like bearings that require low friction.

- Consistent Quality: High-speed lathes ensure repeatability in mass production.

Our expertise at CNCRUSH guarantees precision in producing CNC Turned parts that exceed client expectations.

7. The Impact of Surface Finish on Functionality

Surface finish directly impacts the performance of machined components. A rough surface can cause friction, leading to wear and tear, while a smooth finish improves functionality and aesthetics.

| Surface Finish | Method | Applications |

|---|---|---|

| Polished | Buffing | Decorative components |

| Anodized | Electrochemical | Corrosion resistance for aluminum |

| Matte Finish | Sandblasting | Aesthetic and anti-glare parts |

Pro Tip: Consider post-machining treatments like anodizing to enhance the durability of CNC machined parts.

8. How Automation Enhances Precision in CNC Machining

Automation in CNC machining reduces reliance on manual processes, resulting in higher precision and efficiency. With robotic arms and automated tool changers, manufacturers can produce large batches with consistent quality.

Advantages of Automation:

- Reduced labor costs

- Enhanced repeatability

- Faster production cycles

At CNCRUSH, automation plays a central role in our production, enabling us to deliver high-quality results at competitive prices.

9. Cost Implications of Precision in CNC Machining

While precision machining may have higher initial costs, it saves money in the long run by reducing rework, material waste, and component failure.

| Cost Factor | Impact |

|---|---|

| Reduced Waste | Minimizes material costs |

| Improved Accuracy | Lowers defect rates |

| Longer Part Lifespan | Reduces replacement costs |

Clients of CNCRUSH benefit from our focus on precision, which translates into cost-effective solutions for automotive, machine building, and automation projects.

10. Why Choose CNCRUSH for Precision CNC Machining Services?

With 12 years of expertise, CNCRUSH has become a trusted partner for clients worldwide. Our capabilities in CNC Milled parts and CNC Turned parts set us apart in delivering high-quality solutions tailored to diverse needs.

Our Strengths:

- Advanced equipment, including 5-axis machines and CMM inspection tools

- Expertise in machining aluminum, steel, brass, and plastics

- Affordable and reliable CNC machining services

Visit our website, CNCRUSH, to explore how our services can enhance your next project.

FAQs About CNC Machining for Complex Geometries

Q: What industries benefit most from CNC machining services?

A: Industries such as aerospace, automotive, and automation heavily rely on CNC machining for producing precise components.

Q: How does CNCRUSH ensure quality in CNC machined parts?

A: We use advanced inspection tools, including CMM, to verify dimensions and tolerances.

Q: Can CNCRUSH handle small batch production?

A: Yes, we provide flexible solutions for both prototypes and mass production.

By choosing CNCRUSH, you gain access to a team committed to delivering precision CNC machining services that exceed expectations. Contact us today to start your next project!