In today’s fast-paced manufacturing landscape, CNC machining has emerged as a game-changing technology for producing high-precision metal parts. With its unparalleled accuracy, efficiency, and adaptability, CNC machining ensures that manufacturers stay competitive while meeting the highest quality standards. For over 12 years, CNCRUSH, a leading China CNC factory, has been at the forefront of providing CNC machining services, specializing in CNC Milled parts and CNC Turned parts for industries like automotive, machine building, and automation.

This article explores the benefits of CNC machining for precision metal parts and why companies worldwide trust CNC technology for critical applications. From reduced material waste to the ability to handle complex geometries, CNC machining represents the pinnacle of modern manufacturing.

What Makes CNC Machining Essential for Precision Metal Parts?

CNC precision machining, or Computer Numerical Control machining, is a manufacturing process that uses pre-programmed software to control machinery. This technology offers unmatched precision, making it indispensable for creating high-quality CNC precision machining components across various industries.

For applications like aerospace engine parts or automotive components, where precision and durability are non-negotiable, CNC precision machining delivers:

- Exceptional accuracy: Tolerances as tight as ±0.01 mm.

- Repeatable quality: Consistent results, even in large production runs.

- Wide material compatibility: Capable of machining aluminum, steel, brass, and plastics.

At CNCRUSH, we harness CNC technology to provide world-class CNC precision machining services, ensuring our clients receive parts that meet or exceed their specifications.

Enhanced Precision and Accuracy with CNC precision Machining

Precision is at the heart of CNC machining, making it ideal for industries requiring parts with tight tolerances and consistent quality. CNC machines are programmed to follow intricate designs, ensuring that every piece produced matches the blueprint exactly.

| Feature | Impact on Manufacturing |

|---|---|

| Tight Tolerances | Reduces errors, ensuring perfect fit |

| Automation and Control | Eliminates human error in production |

| Multi-Axis Capabilities | Allows precision machining of complex parts |

For over a decade, CNCRUSH has perfected the art of precision machining, delivering components that meet stringent industry standards. Whether for CNC Milled parts or CNC Turned parts, our expertise ensures superior results.

The Versatility of CNC Milled Parts and CNC Turned Parts

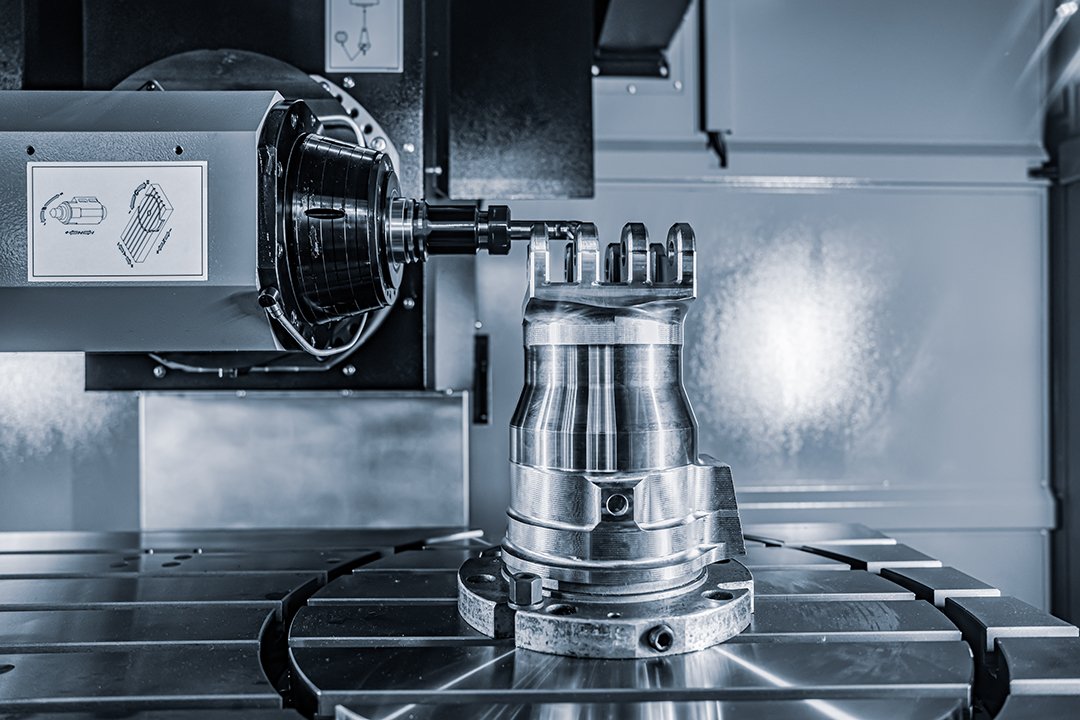

CNC machining encompasses two main processes: milling and turning, each suited to specific applications.

- CNC Milled Parts:

- Produced using multi-axis milling machines.

- Ideal for creating complex geometries, holes, and pockets.

- Widely used in structural applications like frames and brackets.

- CNC Turned Parts:

- Manufactured by rotating a workpiece against cutting tools.

- Perfect for cylindrical shapes, shafts, and connectors.

- Essential for aerodynamics and fluid dynamics in engineering.

At CNCRUSH, our advanced machinery ensures the efficient production of both CNC milled and turned parts, tailored to your exact needs.

CNC Machining for Complex Geometries

Modern designs often involve intricate and unconventional geometries that traditional machining methods struggle to achieve. CNC precision machining excels in producing such components with ease, thanks to:

- 5-axis machining: Allows simultaneous movement along multiple axes, enabling complex contours.

- Tool versatility: Adapts to unique shapes and features like internal channels or undercuts.

This capability is especially valuable in industries like automotive and aerospace, where component functionality often depends on precision-engineered shapes.

The Cost Efficiency of CNC Machining Services

Although CNC precision machining requires an initial investment, its cost efficiency over time makes it a smart choice for manufacturers:

- Reduced waste: Precision cutting ensures optimal material usage.

- Lower labor costs: Automation reduces the need for manual intervention.

- Faster production times: Shorter cycles translate into lower overall costs.

With CNCRUSH’s affordable CNC machining solutions, clients benefit from both high-quality outputs and competitive pricing, making us a leader among China CNC factories.

Speed and Scalability in CNC Machining

CNC machining’s automation and programming capabilities enable manufacturers to scale production without compromising quality:

- Rapid prototyping: Quickly produce prototypes for testing and iteration.

- Batch production: Seamlessly transition from small to large volumes.

- Shorter lead times: Automation minimizes delays, ensuring timely delivery.

Our facility at CNCRUSH is equipped to handle projects of all sizes, from single prototypes to mass production, ensuring consistent quality and on-time delivery.

Material Compatibility in CNC Machining

CNC machining’s versatility extends to its ability to work with a wide range of materials, including:

- Aluminum: Lightweight, corrosion-resistant, and perfect for aerospace and automotive.

- Steel: Durable and robust, ideal for structural and high-load applications.

- Plastics: Used in non-load-bearing parts and insulation.

- Brass: Combines strength and aesthetic appeal for connectors and fittings.

At CNCRUSH, we specialize in machining diverse materials to meet our clients’ unique requirements, whether for CNC precision machining aluminum or CNC plastic machining.

Applications of CNC Machining in Automotive, Machine Building, and Automation

CNC machining plays a vital role in industries such as:

- Automotive: Produces engine components, transmission parts, and more.

- Machine Building: Supports custom machine parts with precise fits.

- Automation: Creates parts for robotics and automated systems.

CNCRUSH’s experience in these sectors ensures that our clients receive custom CNC solutions that align with their specific goals.

Sustainability Benefits of CNC Machining

As industries prioritize sustainability, CNC machining supports eco-friendly manufacturing through:

- Efficient material usage: Reduces waste compared to traditional methods.

- Energy-efficient processes: Modern machines optimize energy consumption.

- Recyclable outputs: Materials like aluminum and steel are fully recyclable.

At CNCRUSH, we are committed to adopting sustainable practices, ensuring minimal environmental impact while delivering high-quality CNC precision machining services.

Why CNCRUSH is the Go-To Provider for CNC Machining Services

With over 12 years of experience, CNCRUSH has built a reputation as a reliable partner for CNC precision machining services. Our advanced facilities and skilled team make us the preferred choice for clients worldwide.

Why Choose CNCRUSH?

- Expertise: Decades of experience in CNC Milled parts and CNC Turned parts.

- State-of-the-art machinery: Ensures precision and efficiency.

- Global trust: Serving industries across automotive, machine building, and automation.

FAQ

What is CNC machining?

CNC machining uses automated tools controlled by pre-programmed software to create precise parts from various materials.

What materials can CNCRUSH machine?

We specialize in machining aluminum, steel, plastics, and brass, among others.

Why choose CNCRUSH for CNC machining services?

With over 12 years of experience and advanced facilities, we deliver precise, affordable, and reliable machining services.

In a world where precision and quality are paramount, CNC machining stands as a beacon of innovation and reliability. At CNCRUSH, we are proud to offer CNC machining services that cater to a diverse range of industries, ensuring excellence every step of the way. Visit our website to learn how we can transform your manufacturing processes.