Precision Parts Manufacturing is a cornerstone of modern industry, requiring unparalleled accuracy and efficiency. CNC machining has emerged as an essential tool in meeting these demands, enabling manufacturers to produce CNC Milled parts and CNC Turned parts with exceptional precision. At CNCRUSH, we have over 12 years of experience as a leading China CNC factory, delivering world-class CNC machining services to clients across industries such as automotive, machine building, and automation.

In this article, we explore the critical importance of CNC machining in precision manufacturing, drawing insights from industry experts while demonstrating how CNCRUSH can help you achieve your manufacturing goals.

Table of Contents

- What Makes CNC Machining Indispensable for Precision Parts Manufacturing?

- CNC Milled Parts: Why Precision Matters

- CNC Turned Parts: A Core Element of Modern Manufacturing

- The Role of CNC Machining in Automotive Innovation

- How CNC Machining Benefits Machine Building and Automation

- Material Flexibility in CNC Machining for Precision Parts

- Quality Control: Ensuring Excellence with CNC Machining

- Custom CNC Solutions for Complex Manufacturing Challenges

- Why Choose China for Affordable Precision CNC Machining?

- Future Trends: How CNC Machining is Shaping Advanced Manufacturing

1. What Makes CNC Machining Indispensable for Precision Parts Manufacturing?

CNC machining combines speed, accuracy, and scalability, making it the backbone of precision parts manufacturing. With pre-programmed software controlling the machinery, manufacturers can achieve highly complex designs with tight tolerances.

Why CNC Machining Is Essential:

- Accuracy and Consistency: Ideal for industries like aerospace, automotive, and medical.

- Efficiency: Reduces material waste and shortens lead times.

- Scalability: From prototypes to mass production.

At CNCRUSH, our state-of-the-art equipment ensures each project meets the exacting standards required for precision CNC machining in global industries.

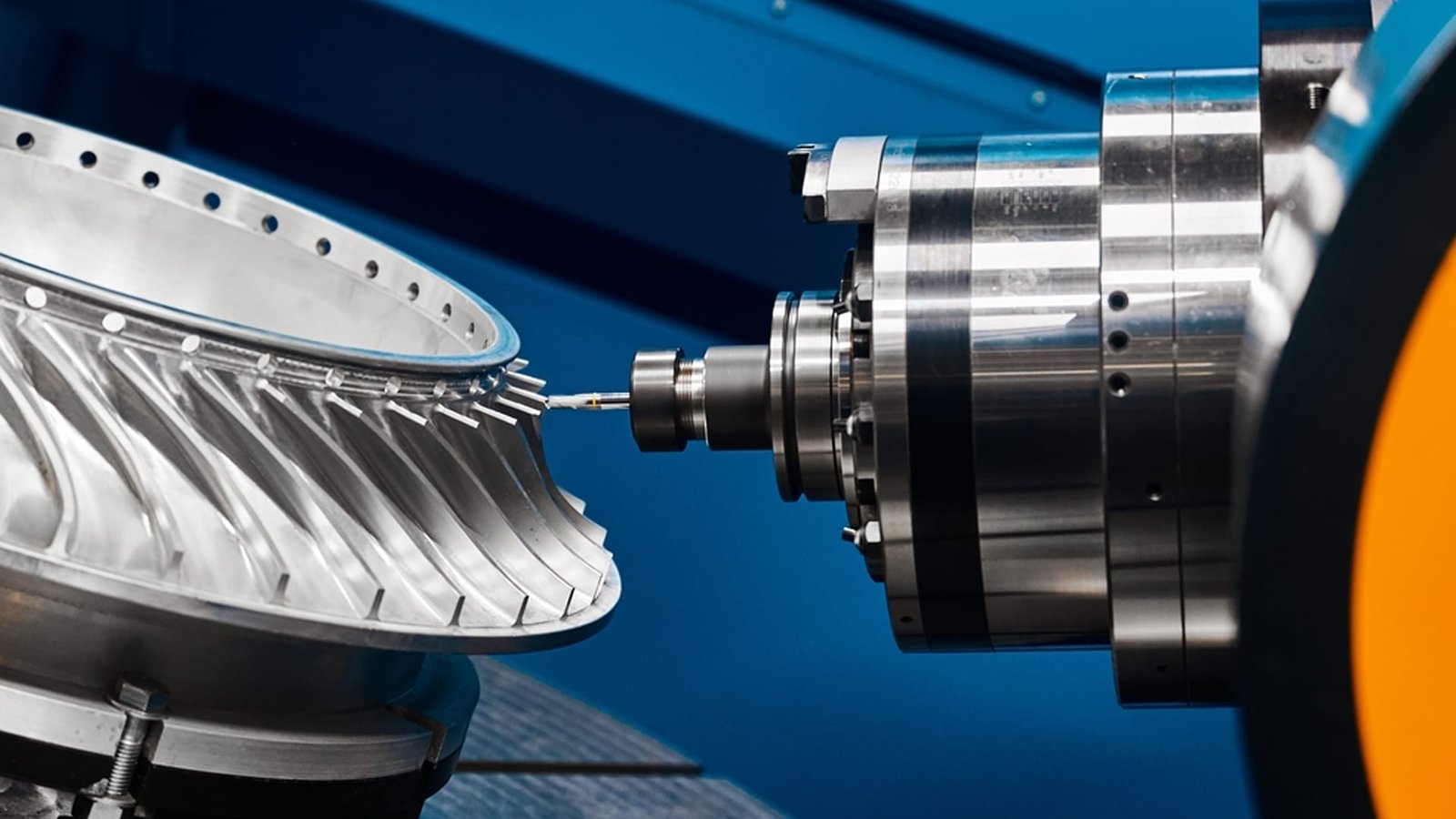

2. CNC Milled Parts: Why Precision Matters

CNC milling is a subtractive process where rotary cutters remove material to achieve the desired shape. Precision in CNC Milled parts is crucial for:

- Engine components

- Aerospace assemblies

- Medical implants

| Benefits of CNC Milled Parts | Applications |

|---|---|

| High precision | Engine blocks, gears |

| Complex geometries | Valve bodies, molds |

| Material versatility | Aluminum, steel, brass |

At CNCRUSH, we specialize in creating CNC Milled parts with intricate designs, leveraging our expertise to meet diverse industry needs.

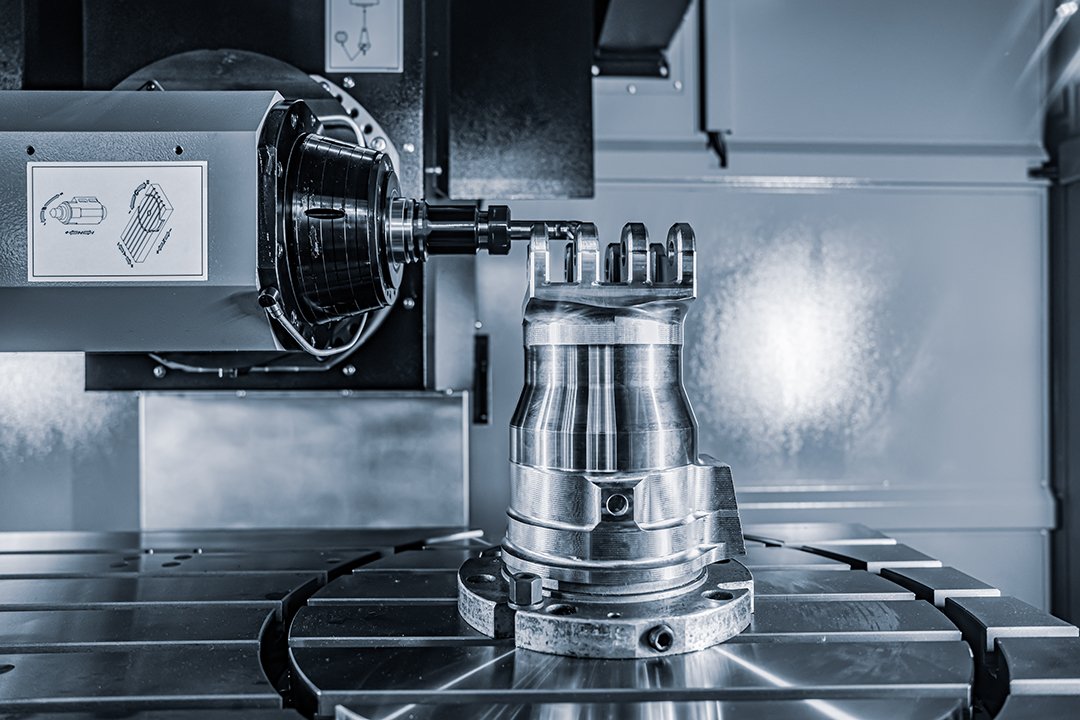

3. CNC Turned Parts: A Core Element of Modern Manufacturing

CNC turning focuses on producing cylindrical parts with high accuracy. These CNC Turned parts play a vital role in mechanical systems, including:

- Hydraulic cylinders

- Bearings

- Shafts and spindles

Advantages of CNC Turned Parts at CNCRUSH:

- Exceptional roundness and symmetry.

- Fast production for large orders.

- Compatibility with various materials like aluminum, steel, and plastics.

By offering comprehensive CNC machining services, we help clients optimize their production processes with reliable CNC Turned parts.

4. The Role of CNC Machining in Automotive Innovation

The automotive industry demands precise components that meet rigorous safety and performance standards. CNC machining is indispensable in producing:

- Engine components: Such as pistons, cylinder heads, and crankshafts.

- Lightweight parts: Using materials like aluminum and magnesium for fuel efficiency.

- Custom parts: For high-performance and electric vehicles.

CNCRUSH has extensive experience serving the automotive sector, delivering custom CNC parts tailored to evolving industry requirements.

5. How CNC Machining Benefits Machine Building and Automation

In machine building and automation, precision is paramount. CNC Precision Parts Manufacturing enables the production of parts that integrate seamlessly into complex systems.

Applications in Automation:

- Robot arms and joints.

- Conveyor system components.

- Custom tool assemblies.

At CNCRUSH, our custom CNC solutions empower manufacturers to innovate and streamline their automation processes.

6. Material Flexibility in CNC Machining for Precision Parts

The ability to work with a variety of materials is a hallmark of CNC machining. Each material offers unique benefits for different industries:

| Material | Applications |

|---|---|

| Aluminum | Automotive, aerospace |

| Steel | Heavy machinery, structural parts |

| Brass | Electrical components, fittings |

| Plastics | Medical devices, prototypes |

CNCRUSH provides CNC machining for metal parts and CNC plastic machining, ensuring the right material is chosen for every project.

7. Quality Control: Ensuring Excellence with CNC Machining

Precision parts require rigorous quality control to ensure they meet specifications. CNC machining offers built-in consistency, while additional checks enhance reliability.

How CNCRUSH Maintains Quality:

- Advanced inspection tools for tight tolerances.

- Detailed testing at each production stage.

- ISO-certified processes for global clients.

Our dedication to quality makes CNCRUSH a trusted name in high-quality Precision Parts Manufacturing.

8. Custom CNC Solutions for Complex Precision Parts Manufacturing Challenges

Custom manufacturing often involves unique challenges. CNC machining rises to these demands with flexible programming and innovative techniques.

Examples of Custom CNC Solutions:

- Prototyping new designs for startups.

- Replacing obsolete parts in legacy systems.

- Producing unique components for experimental applications.

With CNCRUSH, you gain access to experts in custom CNC parts manufacturing, capable of turning the most ambitious ideas into reality.

9. Why Choose China for Affordable Precision CNC Machining?

China has become the global leader in manufacturing, offering unmatched value for Precision Parts Manufacturing.

Benefits of Partnering with CNCRUSH:

- Competitive pricing without sacrificing quality.

- Skilled workforce and advanced technology.

- Reliable logistics for international delivery.

As a China CNC factory with over a decade of experience, CNCRUSH provides the perfect balance of affordability and precision.

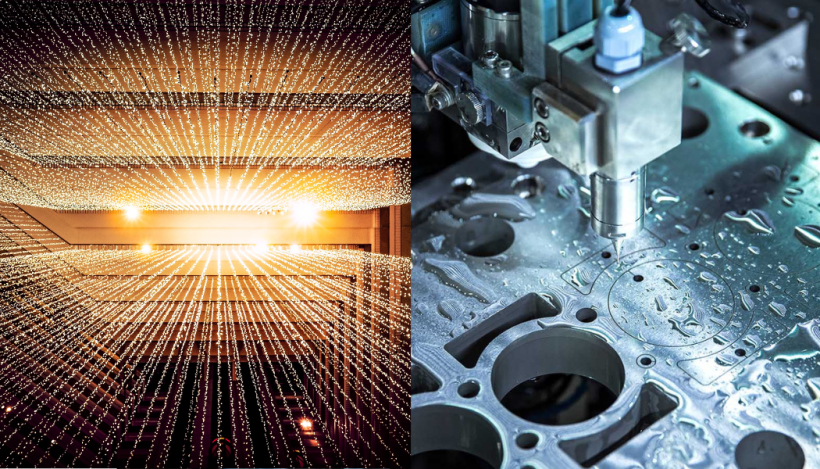

10. Future Trends: How CNC Machining is Shaping Advanced Manufacturing

The future of CNC machining is tied to advancements in automation, AI, and material science.

Emerging Trends Include:

- AI-driven predictive maintenance.

- Hybrid manufacturing combining CNC with additive techniques.

- Sustainable machining with eco-friendly practices.

CNCRUSH stays at the forefront of these innovations, continuously upgrading our capabilities to meet tomorrow’s demands.

FAQ: Precision Parts Manufacturing

Q: What industries rely on CNC machining for precision parts manufacturing?

A: CNC machining is essential for industries like automotive, aerospace, medical, and machine building.

Q: Why should I choose CNCRUSH for CNC machining services?

A: With 12 years of experience, we provide high-quality, affordable solutions tailored to your needs.

Q: Can CNCRUSH handle small and large production runs?

A: Yes, we specialize in both prototyping and mass production.

Q: What materials can CNCRUSH process?

A: We work with a wide range of materials, including aluminum, steel, brass, and plastics.

At CNCRUSH, we’re dedicated to delivering the highest quality CNC machining services, specializing in CNC Milled parts and CNC Turned parts. Contact us today to discover how we can bring precision and excellence to your Precision Parts Manufacturing.