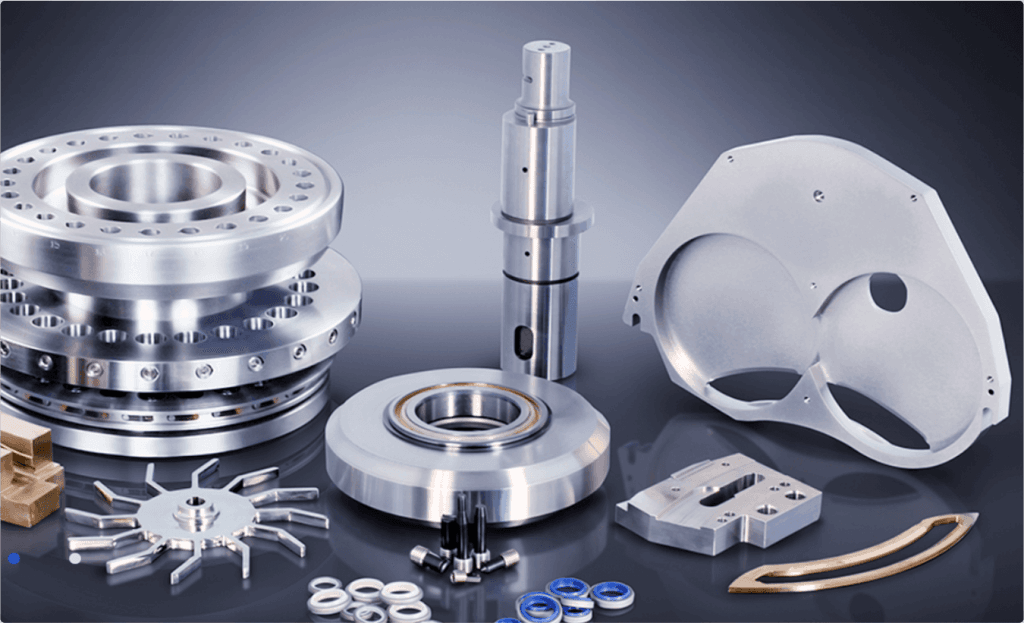

In today’s competitive manufacturing environment, CNC machining has become the cornerstone of small-part production, especially in industries demanding high precision and reliability. Whether creating miniature components for automotive systems, medical devices, or aerospace applications, CNC machining ensures unmatched accuracy and scalability. CNCRUSH, a China-based CNC machining factory with over 12 years of experience, is dedicated to offering CNC Milled parts, CNC Turned parts, and custom CNC solutions for global clients in sectors like automotive, machine building, and automation.

This article delves into why CNC machining services are the preferred solution for manufacturing small parts and how they contribute to precision, efficiency, and innovation.

Why CNC Machining Is Essential for Small Parts Manufacturing

Manufacturing small parts comes with unique challenges, such as maintaining tight tolerances, achieving intricate geometries, and reducing material waste. CNC machining overcomes these hurdles with advanced capabilities, offering:

- Unmatched Precision: CNC machines deliver tolerances as tight as ±0.001 mm, critical for components in safety-critical applications like engines and electronics.

- High Repeatability: Once programmed, CNC machines replicate the same design flawlessly across high production volumes.

- Material Versatility: CNC machining supports metals (like aluminum, steel, and brass) and plastics, making it adaptable to a wide range of industries.

These advantages position CNC machining as the go-to solution for manufacturing small, high-precision parts.

Benefits of CNC Machining for Small Parts

Precision Redefined

Small parts often require exceptional accuracy to ensure they fit perfectly in larger assemblies. CNC machining achieves this through:

- High-speed spindles: Enabling precise micro-milling for tiny features.

- Automated error correction: Sensors detect and adjust for inconsistencies during the process.

This precision ensures that components like gears, fasteners, and connectors meet stringent quality standards.

Flexibility and Scalability

CNC machining is ideal for both small-batch prototypes and large-scale production. This flexibility ensures manufacturers can adapt quickly to market demands without compromising efficiency. For instance:

- Prototyping: Rapid turnaround for testing and refinement.

- Production: Scalable operations allow for cost-effective manufacturing of thousands of identical parts.

CNCRUSH’s expertise in CNC milling and turning ensures that clients receive fast, reliable services, whether they need a single prototype or a high-volume production run.

Material Options for Versatility

CNC machining supports a broad spectrum of materials, enabling manufacturers to choose the right substrate for their application:

- Aluminum and Steel: Lightweight and durable, ideal for small automotive parts.

- High-Performance Plastics: Perfect for medical devices and electrical insulation.

This versatility allows CNCRUSH to deliver customized solutions for diverse industries.

Applications of CNC Machining in Small-Part Manufacturing

Automotive Industry

In the automotive sector, small parts like fasteners, connectors, and bushings play a critical role in system reliability. CNC machining ensures these components meet exact specifications, improving safety and performance.

Medical Devices

From surgical instruments to micro-implants, CNC machining’s precision makes it indispensable for the medical industry. High tolerances ensure compatibility with human anatomy and medical equipment.

Aerospace Components

The aerospace industry requires lightweight, small-scale parts like turbine blades and sensor mounts. CNC machining enables these parts to be manufactured with tight tolerances and minimal material waste.

How CNC Milling and Turning Enhance Small-Part Manufacturing

CNC Milling for Complex Geometries

CNC milling excels in creating intricate shapes, even at small scales. Multi-axis machines can produce complex components like microvalves and intricate molds with exceptional detail.

CNC Turning for Cylindrical Components

CNC turning is ideal for producing small cylindrical parts like shafts, rods, and rings. With automated tooling, CNC turning achieves high-speed production without sacrificing precision.

At CNCRUSH, we combine CNC milling and turning to meet the diverse needs of our clients, ensuring all components are manufactured to the highest standards.

Advantages of Micro-Machining with CNC

Micro-machining, a specialized form of CNC precision machining, is tailored for extremely small parts. Key benefits include:

- High Precision: Ideal for parts as small as a few micrometers.

- Superior Surface Finish: Minimizes the need for additional processing.

- Wide Material Compatibility: Works with metals, plastics, and composites.

Micro-machining is invaluable in industries like electronics, where small components like circuit boards require exact dimensions and finishes.

Cost Efficiency of CNC precision Machining for Small Parts

Despite its advanced capabilities, CNC machining is a cost-effective solution. Factors contributing to cost savings include:

- Reduced Material Waste: Optimized cutting paths minimize waste.

- Automation: Lowers labor costs and reduces production errors.

- Energy Efficiency: Modern CNC machines consume less power, reducing operational expenses.

Table 1: Comparison of CNC Milling and Turning for Small Parts

| Process | Best For | Advantages |

|---|---|---|

| CNC Milling | Complex geometries | High precision, multi-axis capabilities |

| CNC Turning | Cylindrical components | Fast production, excellent repeatability |

Table 2: Popular Materials for Small-Part CNC precision Machining

| Material | Advantages | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive, aerospace |

| Stainless Steel | Strong, heat-resistant | Medical devices, industrial equipment |

| High-Performance Plastics | Lightweight, durable | Electronics, medical implants |

Frequently Asked Questions

What makes CNC precision machining suitable for small parts?

CNC machining’s precision and repeatability make it ideal for manufacturing small parts, ensuring exact dimensions and consistent quality.

Why choose CNCRUSH for CNC precision machining services?

With over 12 years of expertise, CNCRUSH offers high-quality CNC Milled parts and CNC Turned parts, leveraging advanced technology to meet global standards.

Which industries benefit most from small-part CNC precision machining?

Industries like automotive, medical, and aerospace rely on CNC precision machining for producing small, high-precision components.

Conclusion

For manufacturers looking to produce small, high-precision parts, CNC precision machining services are indispensable. By combining advanced technology with material versatility, CNC machining ensures consistent quality, scalability, and cost efficiency. With its expertise in CNC Milled parts, CNC Turned parts, and custom CNC solutions, CNCRUSH is your trusted partner for small-part manufacturing. Explore our services today and experience the difference CNC machining can make for your projects.

Additionally, CNC machining is driving innovation in small-part production by integrating advanced technologies like IoT-enabled monitoring and AI-driven automation. These tools allow real-time adjustments to optimize cutting paths, detect anomalies, and reduce downtime, ensuring consistently high-quality output. For example, IoT sensors provide insights into machine performance and tool wear, preventing costly errors. This advanced level of control not only enhances precision but also aligns with sustainability goals by minimizing energy consumption and material waste. With CNCRUSH’s investment in such cutting-edge technology, clients benefit from a seamless manufacturing process that combines efficiency, precision, and environmental responsibility.