CNC machining has revolutionized manufacturing, particularly in industries where precision, efficiency, and durability are paramount. In aerospace, where safety and performance are non-negotiable, CNC machining plays a central role. From lightweight titanium components to complex geometries in aluminum and steel, CNC machining drives innovation while ensuring reliability. If you are seeking premium CNC machining services for aerospace or other industries, look no further than CNCRUSH. As a trusted China CNC factory with over 12 years of expertise, we specialize in delivering CNC Milled parts and CNC Turned parts tailored to your needs.

The Role of CNC Machining in Aerospace Manufacturing

Aerospace manufacturing demands unparalleled precision due to the high-stakes environment in which components operate. From structural components to engine parts, CNC machining ensures accuracy, repeatability, and cost-efficiency, enabling the production of parts that meet stringent safety and performance standards. Below, we delve into the top aspects of CNC machining in aerospace manufacturing, along with insights into how CNCRUSH can be your ideal partner in this journey.

What Makes CNC Machining Indispensable in Aerospace Manufacturing?

Aerospace manufacturing requires parts to withstand extreme forces, temperatures, and wear. CNC Precision machining offers:

- Precision: Tolerances as tight as ±0.005 mm ensure components fit perfectly.

- Repeatability: Every batch of parts matches exact specifications, reducing variability.

- Efficiency: CNC machines produce parts faster, minimizing lead times without sacrificing quality.

At CNCRUSH, we enhance these benefits by utilizing advanced CAD/CAM software and state-of-the-art CNC mills and lathes. With our expertise in CNC Precision machining services, we deliver consistent results to clients in the aerospace, automotive, and machine-building sectors.

The Materials of Choice in Aerospace CNC Machining

CNC Precision machining in aerospace involves diverse materials tailored to specific performance requirements:

| Material | Properties | Applications |

|---|---|---|

| Titanium | Lightweight, high strength, corrosion resistance | Structural frames, engine components |

| Aluminum | Lightweight, excellent machinability, conductive | Fuselage parts, wings, and avionics housings |

| Steel | Strength, durability | Landing gear, structural reinforcements |

| Composites | Extreme strength-to-weight ratio | Interior components, secondary structures |

Our factory at CNCRUSH is equipped to process these materials with unmatched accuracy, offering custom CNC solutions for a wide range of needs.

CNC Milled Parts for Aerospace: Precision in Action

CNC Milled parts are critical in aerospace for creating intricate shapes, slots, and cavities in components. From avionics housings to structural connectors, milling ensures:

- High surface quality for smooth airflow.

- Complex 3D geometries with high precision.

- Material versatility, from lightweight metals to composites.

At CNCRUSH, we excel in precision CNC machining, using multi-axis CNC mills to achieve extraordinary accuracy. Whether you require prototypes or large production runs, our team ensures every detail aligns with your design intent.

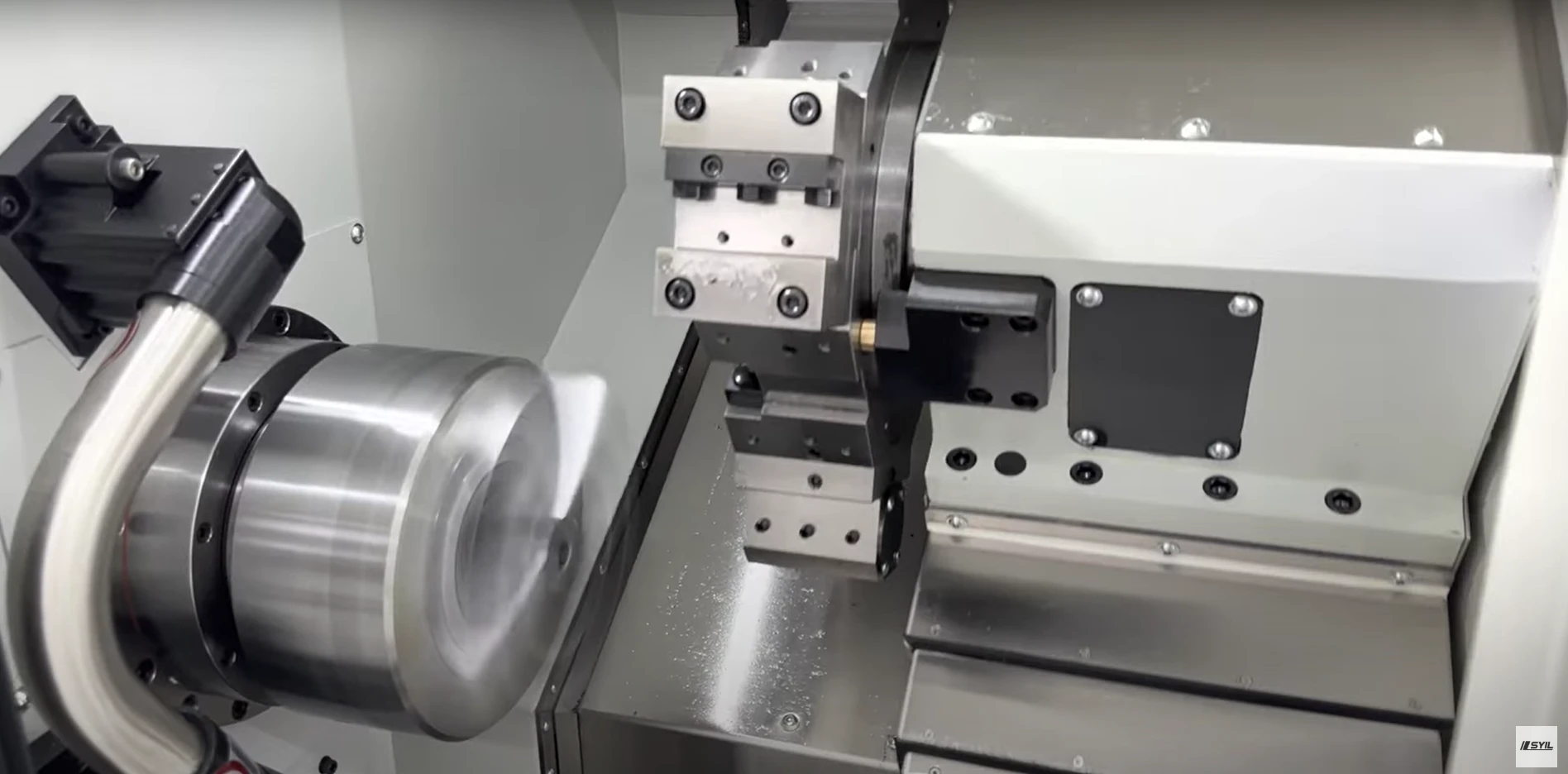

CNC Turned Parts in Aerospace Manufacturing

CNC Turned parts, such as shafts, bushings, and fasteners, are integral to aircraft systems. Turning processes achieve:

- Symmetrical parts with exceptional concentricity.

- Efficient production of high-volume cylindrical components.

- Reduced material waste through optimized programming.

Our advanced CNC lathes enable the production of high-precision turned parts with tight tolerances. Trust CNCRUSH to deliver CNC Turned parts that perform flawlessly in critical aerospace applications.

How CNC Machining Supports Lightweight Design in Aerospace

Reducing weight is crucial for enhancing fuel efficiency and payload capacity. Precision machining achieves lightweight designs by:

- Allowing thinner walls and optimized geometries.

- Processing lightweight materials like titanium and aluminum with precision.

- Minimizing assembly by machining complex parts in one piece.

Our expertise in CNC machining aluminum and other lightweight materials ensures components meet aerospace weight-reduction goals without compromising strength.

Advantages of Precision machining for Complex Geometries

The aerospace industry demands intricate parts with high precision, such as turbine blades and fuel injection nozzles. Precision machining enables:

- Multi-axis operations for producing complex designs.

- Simultaneous milling and turning, reducing setup times.

- Freedom of design, allowing engineers to innovate without constraints.

By partnering with CNCRUSH, you gain access to cutting-edge multi-axis machining solutions for even the most challenging designs.

Quality Assurance and Inspection in Aerospace CNC Machining

In aerospace, quality is non-negotiable. Precision machining facilitates rigorous quality control through:

- In-process monitoring, ensuring every part meets specifications.

- Coordinate Measuring Machines (CMM) for post-production inspection.

- Adherence to international standards like AS9100.

At CNCRUSH, we integrate quality control into every step of the process, ensuring your Precision machining services meet the highest benchmarks.

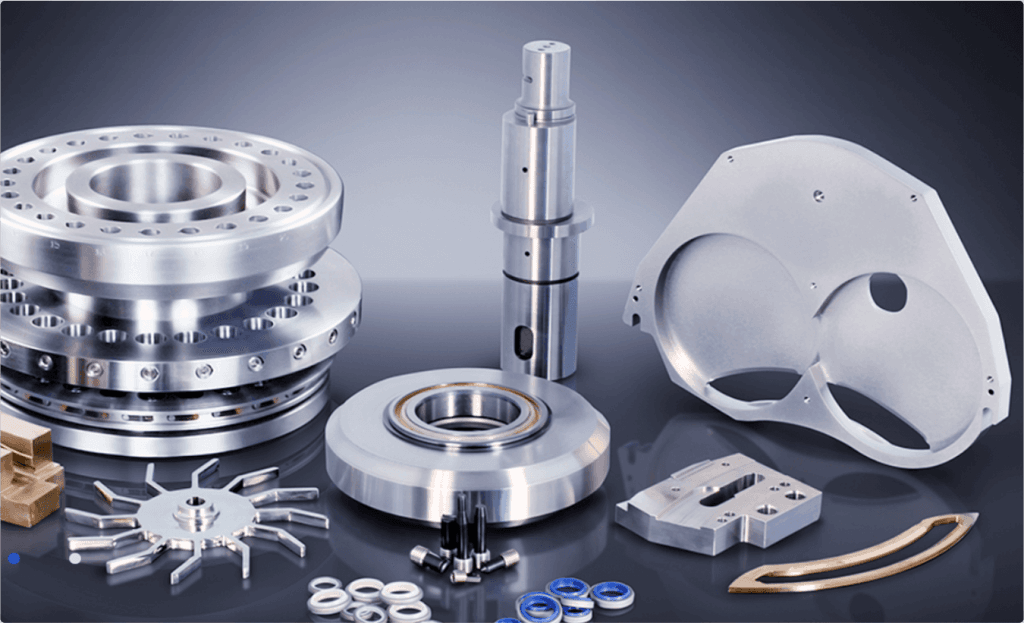

Applications of Precision machining Beyond Aerospace

While aerospace benefits enormously from CNC machining, its applications extend to:

- Automotive: High-performance engines, gearboxes, and suspension parts.

- Machine building: Custom tooling and precision components.

- Automation: Robotic parts and custom automation equipment.

Our custom CNC solutions cater to a wide range of industries, offering the same level of precision and expertise we bring to aerospace.

Why Choose CNCRUSH for CNC Machining Services?

When it comes to CNC machining in China, CNCRUSH stands out for:

- Experience: Over 12 years in CNC manufacturing services.

- Global Reach: Trusted by clients worldwide.

- Custom Solutions: Tailored services for CNC Milled parts and CNC Turned parts.

- Affordability: High-quality machining at competitive prices.

Partnering with us ensures access to a dedicated team of experts ready to meet your exacting demands.

FAQ: Aerospace CNC Machining and Our Services

Q: What materials do you specialize in machining for aerospace?

A: We excel in machining aluminum, titanium, steel, and composites, ensuring every material meets aerospace-grade standards.

Q: Can you handle prototypes and high-volume production?

A: Yes, our facility supports both one-off prototypes and large-scale production runs with consistent quality.

Q: How do you ensure precision in your parts?

A: We use advanced CAD/CAM systems, multi-axis CNC machines, and stringent quality control processes to ensure precision.

Q: Why choose CNCRUSH for Precision machining services?

A: Our experience, global client base, and focus on quality and affordability make us the ideal partner for all your Precision machining needs.

Conclusion

CNC machining is the backbone of aerospace manufacturing, driving precision, innovation, and efficiency. For over a decade, CNCRUSH has been a trusted partner for businesses worldwide, delivering high-quality CNC machining services for aerospace and beyond. Whether you need CNC Milled parts, CNC Turned parts, or customized solutions for automotive and machine building, our expertise ensures your success. Contact us today to discover how we can help bring your designs to life.

Explore more about our services at CNCRUSH.