The Automotive Parts Manufacturing industry is a highly competitive sector where efficiency, precision, and cost-effectiveness are paramount. In recent years, CNC (Computer Numerical Control) machining has become a game-changer for automotive parts manufacturing, providing remarkable advancements in both production speed and accuracy. In this article, we will explore how CNC machining improves the efficiency of manufacturing automotive parts, focusing on the benefits of CNC milled parts and CNC turned parts. As a company with over 12 years of expertise in offering CNC machining services in China, CNCRUSH is well-positioned to provide innovative solutions for the automotive industry. Whether you need high-quality CNC milled parts or CNC turned parts, our expertise in CNC machining can help drive efficiency and reduce manufacturing costs.

1. The Role of CNC Machining in Automotive Parts Manufacturing

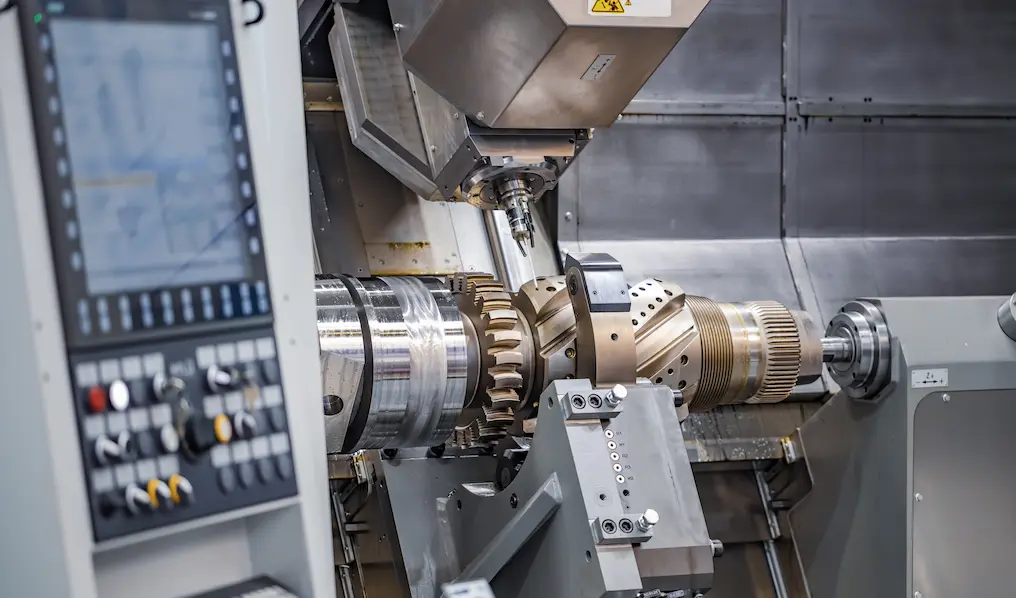

CNC machining plays a crucial role in modern automotive parts manufacturing. With its ability to automate intricate processes, CNC machines significantly reduce the labor costs and human errors that are common in traditional manufacturing methods. CNC machining provides the automotive industry with high-precision, repeatable results, making it ideal for producing complex automotive parts with strict quality standards.

At CNCRUSH, we specialize in CNC milling and turning, both essential for automotive components. Our services ensure that automotive manufacturers can achieve the tight tolerances and robust durability required for mission-critical components such as engine parts, suspension systems, and transmission components.

2. CNC Milled Parts: Enhancing Accuracy and Quality

CNC milled parts are indispensable in the automotive industry. Milling allows for the creation of parts with extremely tight tolerances and smooth finishes, which are crucial for Automotive Parts Manufacturing that require precision and durability. The use of CNC milling in the production of engine blocks, cylinder heads, and various other automotive components results in parts that meet high-performance standards and reduce the risk of malfunction.

Our CNC milling services at CNCRUSH utilize advanced equipment capable of producing aluminum, steel, and plastic parts with precise dimensions and excellent surface finishes. Whether you need parts for a prototype or a mass production run, our CNC machining services ensure high-quality results that drive the success of your automotive manufacturing processes.

3. CNC Turned Parts: Revolutionizing Component Production

CNC turning, another critical aspect of automotive parts manufacturing, allows for the creation of parts with cylindrical features such as shafts, pistons, and bushings. By using computer-controlled lathes, CNC turning ensures that parts are produced with high precision and repeatability. These parts are essential for the functionality and longevity of various automotive systems, including powertrains and suspension systems.

CNCRUSH’s expertise in CNC turning offers Automotive Parts Manufacturing a reliable solution for creating high-precision turned components at competitive prices. From small to large quantities, our CNC turned parts deliver consistency and efficiency throughout the production process.

4. Reducing Lead Times with CNC Machining

One of the most significant advantages of CNC machining in automotive parts manufacturing is its ability to drastically reduce lead times. Traditional manufacturing methods, such as casting or forging, can take weeks to complete due to the extensive tooling and setup time required. CNC machining, on the other hand, is highly flexible and can quickly produce complex parts with minimal setup time.

By choosing CNCRUSH for your CNC machining services, you can reduce production delays and accelerate time-to-market for your automotive products. Our state-of-the-art facilities, including 3-axis, 4-axis, and 5-axis CNC machines, are equipped to handle high-volume production runs while maintaining the highest levels of precision and efficiency.

5. Cost-Effectiveness in CNC Machining for Automotive Parts

While the initial investment in CNC machinery can be high, the long-term cost savings are substantial. CNC machining reduces the need for expensive tooling, minimizes material waste, and lowers labor costs due to its automation capabilities. These factors make CNC machining an incredibly cost-effective solution for automotive parts manufacturing, especially for high-precision components.

At CNCRUSH, we provide affordable CNC machining services without compromising on quality. Our ability to work with a wide range of materials, including aluminum, steel, and plastics, ensures that automotive manufacturers can obtain cost-effective solutions tailored to their specific needs.

6. CNC Machining for Prototyping Automotive Parts

Prototyping is an essential step in automotive parts development, and CNC machining provides a fast, reliable method for producing prototypes. By using CNC machining, manufacturers can quickly produce functional prototypes of automotive parts, test their performance, and make design adjustments before moving to mass production. This reduces the overall development cycle and helps bring products to market faster.

CNCRUSH’s CNC machining expertise allows us to deliver high-quality prototypes for automotive parts, ensuring that you can refine your designs with confidence. Whether you require CNC milled or CNC turned parts for your automotive prototype, our services will ensure the best possible results.

7. The Impact of CNC Machining on Automotive Part Customization

Customization is increasingly important in the automotive industry, with manufacturers looking to create unique parts for different vehicle models or specific customer needs. CNC machining provides unparalleled flexibility in customization, allowing manufacturers to produce a wide variety of components tailored to specific requirements.

Our CNC machining services at CNCRUSH can be adapted to meet any level of customization, whether you need small-batch, highly specialized parts or large-scale production runs. Our expertise in CNC milled and turned parts ensures that we can deliver precisely the components you need to meet the demands of the automotive industry.

8. Automotive Parts Manufacturing for Increased Productivity

Automation in CNC machining is a key driver of productivity in the automotive industry. By integrating automation systems with CNC machines, manufacturers can streamline their production processes and reduce human error, resulting in more efficient and cost-effective production runs.

At CNCRUSH, we leverage advanced CNC machining technology, such as robotic arms and automated material handling systems, to enhance the efficiency of our production processes. Our fully automated machining systems are designed to deliver consistent results, even in high-volume production runs, ensuring that automotive manufacturers can keep up with the fast-paced demands of the industry.

9. Quality Control in CNC Machining for Automotive Parts

Quality control is critical in the automotive industry, where even the smallest defect in a part can lead to catastrophic failure. CNC machining is an ideal solution for maintaining the highest standards of quality, as it offers precise control over the production process. With advanced inspection tools such as CMM (Coordinate Measuring Machines), CNCRUSH ensures that every part produced meets the exact specifications required by the automotive industry.

Our commitment to quality is reflected in our comprehensive quality control procedures. We provide detailed inspection reports, including FAIR (First Article Inspection Reports) and CMM reports, ensuring that each automotive part we produce is of the highest quality.

10. Future Trends in CNC Machining for Automotive Parts Manufacturing

As the automotive industry continues to evolve, the role of CNC machining will only become more critical. Advances in materials, software, and automation are paving the way for even greater efficiencies in automotive parts manufacturing. The integration of AI (Artificial Intelligence) and machine learning in CNC machining processes is expected to further enhance production capabilities, leading to even faster and more accurate part production.

At CNCRUSH, we are constantly keeping up with the latest technological advancements to ensure that we offer cutting-edge CNC machining services. By adopting the latest trends in CNC machining, we are able to provide innovative solutions that meet the ever-changing demands of the automotive industry.

Table 1: Comparison of CNC Milled and CNC Turned Parts in Automotive Parts Manufacturing

| Feature | CNC Milled Parts | CNC Turned Parts |

|---|---|---|

| Precision | High precision with tight tolerances | High precision, especially for cylindrical parts |

| Material Flexibility | Works well with a variety of materials | Ideal for metal and plastic parts |

| Production Speed | Suitable for complex geometries | Faster production for simpler parts |

| Cost | Typically higher for complex parts | Generally more cost-effective for high volumes |

| Application | Engine blocks, suspension parts, etc. | Shafts, pistons, bushings, etc. |

Table 2: Benefits of CNC Machining for Automotive Parts Manufacturing

| Benefit | Description |

|---|---|

| High Precision | CNC machines can create parts with extremely tight tolerances, reducing the risk of defects. |

| Reduced Lead Time | Faster production times compared to traditional methods, enabling quicker market delivery. |

| Lower Labor Costs | Automated processes reduce the need for skilled labor, resulting in cost savings. |

| Material Efficiency | CNC machining minimizes waste by cutting precisely to specifications, maximizing material use. |

| Scalability | CNC machines can be easily adapted for both small and large production runs. |

FAQ: CNC Machining in Automotive Parts Manufacturing

Q1: What types of automotive parts can be produced with CNC machining?

CNC machining can be used to produce a wide variety of automotive parts, including engine blocks, suspension components, pistons, shafts, and bushings. CNC milled and turned parts are commonly used in the production of high-precision components.

Q2: How does CNC machining improve part accuracy?

CNC machining ensures high accuracy by using computer-controlled machines that follow precise instructions. The process reduces human error and provides repeatable results, making it ideal for producing complex parts with tight tolerances.

Q3: What are the advantages of CNC machining over traditional Automotive Parts Manufacturing methods?

CNC machining offers several advantages over traditional methods, including faster production times, reduced labor costs, greater precision, and less material waste. It is particularly effective for producing complex and customized parts.

Q4: Can CNCRUSH help with automotive prototyping?

Yes, CNCRUSH offers CNC machining services for prototyping automotive parts. Our expertise in both CNC milling and turning ensures that we can produce high-quality prototypes quickly