High-Volume Parts Manufacturing is a cornerstone of industries like automotive, machine building, and automation, where precision, scalability, and efficiency are non-negotiable. At the forefront of this transformative process is CNC machining, which has redefined production possibilities for components made of metals and plastics.

For over 12 years, CNCRUSH has delivered CNC machining services tailored to high-volume demands, producing exceptional CNC Milled parts and CNC Turned parts. This article explores the pivotal role of CNC machining in high-volume manufacturing, offering insights that manufacturers can leverage for their production needs. From its advantages to actionable strategies for efficiency, this guide is your comprehensive roadmap.

Summary of Industry Insights

In high-volume manufacturing, consistency, speed, and adaptability are paramount. CNC machining excels in meeting these requirements, offering unparalleled precision and cost-efficiency. Across the resources studied, several critical points emerge:

- CNC machining is ideal for industries requiring tight tolerances and high repeatability.

- It supports diverse material types, from aluminum to plastics.

- Integration of automation and advanced tooling significantly boosts productivity.

With CNCRUSH as a trusted partner, manufacturers can unlock these advantages for large-scale production.

1. High-Volume Manufacturing and CNC Machining: A Symbiotic Relationship

High-volume manufacturing requires processes that ensure consistent quality over thousands—or even millions—of parts. CNC machining services deliver this by leveraging computer-controlled precision and repeatable workflows.

Benefits of CNC Machining in High-Volume Manufacturing:

- Unmatched Accuracy: Sub-millimeter tolerances ensure consistent quality.

- Scalability: Efficiently handles production runs exceeding 50,000 units.

- Reduced Downtime: Automated systems maximize output without human errors.

At CNCRUSH, we specialize in scaling operations to meet global demand for CNC Milled parts and CNC Turned parts, particularly in industries like automotive and automation.

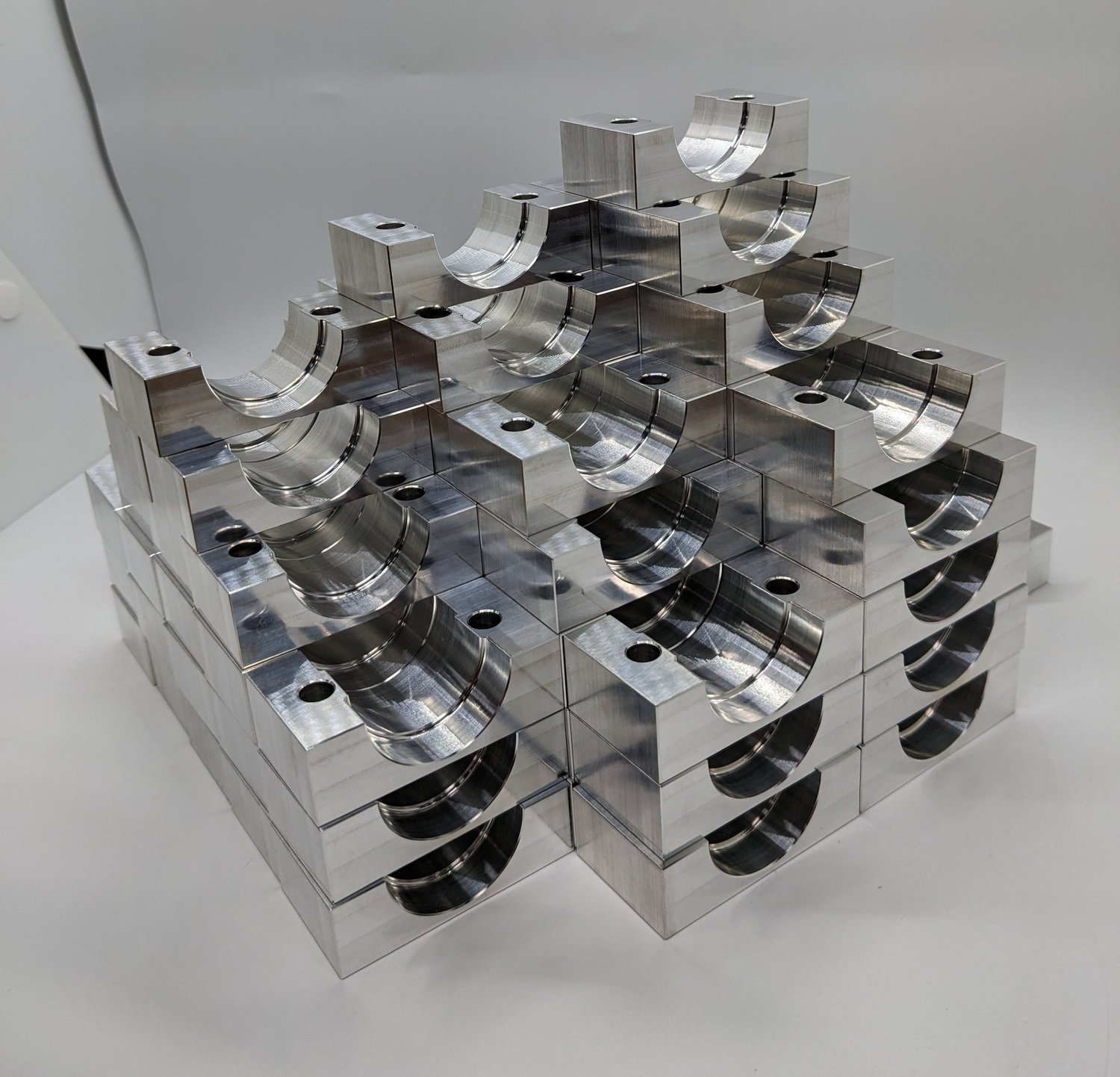

2. CNC Milled Parts: Precision in Complex Geometries

Milling is a crucial CNC process for producing intricate shapes and components. High-volume requirements amplify the need for efficiency and precision.

Why CNC Milled Parts Stand Out:

- Advanced Toolpaths: Optimize material removal rates.

- Material Flexibility: Ideal for aluminum, steel, brass, and plastics.

- Surface Finishes: Achieve superior smoothness, crucial in machine building.

By integrating state-of-the-art milling equipment, CNCRUSH ensures every part meets exacting client specifications, whether for prototypes or mass production.

3. CNC Turned Parts: Efficiency for Cylindrical Components

Turning processes are essential for producing cylindrical parts like shafts, pins, and bushings, which are staples in automotive and automation applications.

Advantages of CNC Turned Parts in High-Volume:

- Fast Cycle Times: Produce large quantities in minimal time.

- Precision Threads and Features: Maintain critical dimensional tolerances.

- Durability: Withstands high-stress applications.

Our expertise in CNC Turned parts supports both small-batch and high-volume runs, making us a trusted custom CNC parts manufacturer.

4. Materials for High-Volume CNC Machining

Material selection is a key determinant of performance, cost, and machining efficiency. CNC machining supports a wide range of materials, offering flexibility for diverse applications.

| Material | Applications | Advantages |

|---|---|---|

| Aluminum | Aerospace, Automotive | Lightweight, corrosion-resistant |

| Steel | Heavy Machinery, Tools | Strength, durability |

| Brass | Electronics, Plumbing | High machinability, conductivity |

| Plastics | Prototyping, Medical Devices | Lightweight, versatile |

At CNCRUSH, we handle all major materials, delivering CNC machining aluminum, steel, brass, and plastics to meet client needs.

5. Automation: The Future of High-Volume Parts Manufacturing

Automation has transformed CNC machining by minimizing human intervention and enhancing efficiency of High-Volume Parts Manufacturing.

Key Innovations:

- Robotic Arms: Enable seamless material handling for 24/7 operations.

- Real-Time Monitoring: IoT devices provide data on machine performance.

- Automated Quality Checks: Ensure zero defects in mass production.

Integrating automation into CNC machining services allows CNCRUSH to maintain rapid turnaround times for even the largest orders.

6. Industry Applications of High-Volume Parts Manufacturing

CNC machining is indispensable across various sectors. Here’s how it supports specific industries:

| Industry | Examples of CNC Machined Parts |

|---|---|

| Automotive | Engine components, gears |

| Machine Building | Precision tools, machine frames |

| Automation | Robotic arm parts, sensors |

| Electronics | Casings, connectors |

Our custom CNC solutions cater to these industries, ensuring high reliability for critical applications.

7. Challenges in High-Volume Parts Manufacturing and How to Overcome Them

High-Volume Parts Manufacturing introduces unique challenges, such as maintaining consistency and optimizing costs.

Solutions:

- Tool Life Management: Regularly monitor and replace tools.

- Batch Scheduling: Efficiently allocate resources for different orders.

- Proactive Maintenance: Prevent costly machine downtime.

With our extensive experience, CNCRUSH anticipates and addresses these challenges to keep production on track.

8. The Economic Advantage of CNC Machining in High-Volume Parts Manufacturing

Cost efficiency is a major driver for manufacturers opting for CNC machining in High-Volume Parts Manufacturing.

Cost-Saving Factors:

- Reduced Waste: Precision minimizes material loss.

- Labor Efficiency: Automated systems reduce reliance on manual labor.

- Long-Term Reliability: Machines require minimal recalibration.

These savings make CNCRUSH a trusted partner for affordable CNC machining services, whether for startups or established enterprises.

9. Scaling High-Volume CNC Machining Operations

Scaling from prototyping to full-scale production requires meticulous planning and reliable machinery.

Steps to Scale:

- Prototype Validation: Test designs for manufacturability.

- Flexible Machines: Invest in equipment that adapts to varying batch sizes.

- Strategic Partnerships: Collaborate with experts like CNCRUSH.

Our team specializes in helping clients navigate the scaling process, ensuring consistent quality from the first piece to the millionth.

10. CNCRUSH: Your Partner for High-Volume Parts Manufacturing

For over a decade, CNCRUSH has been at the forefront of high-quality CNC machining, serving clients worldwide.

Why CNCRUSH?

- Global Expertise: Clients across Europe, the US, and Asia trust us.

- Custom Solutions: Tailored to your specific needs in CNC milling and turning.

- Advanced Technology: Industry-leading equipment for precision production.

When you need reliability, scalability, and quality, CNCRUSH is your ideal partner for High-Volume Parts Manufacturing.

FAQ: High-Volume Parts Manufacturing

Q: What types of parts are best suited for CNC machining?

A: CNC machining is ideal for components requiring high precision, including gears, shafts, and casings used in automotive, automation, and machine building.

Q: How does CNC machining ensure consistency in high-volume runs?

A: CNC machines rely on pre-programmed software, maintaining exact tolerances across thousands of parts.

Q: Why is CNC machining cost-effective for high-volume production?

A: Automation, material efficiency, and minimal errors contribute to significant cost savings over traditional manufacturing methods.

Conclusion: Power Your Production with CNCRUSH

High-Volume Parts Manufacturing demands excellence, efficiency, and adaptability—qualities embodied by CNC machining services. At CNCRUSH, our expertise in producing CNC Milled parts and CNC Turned parts has made us a global leader in precision CNC machining. Whether you’re scaling a new product or meeting the demands of a competitive market, we’re here to transform your vision into reality. Reach out today and experience the CNCRUSH advantage!