In the evolving landscape of modern manufacturing, CNC machining stands out as one of the most influential technological advancements. The integration of automation, precision, and flexibility into manufacturing has reshaped how industries like automotive, aerospace, medical, and machine building operate. From prototyping to mass production, CNC machining’s transformative power continues to redefine the standards of efficiency, quality, and scalability in the sector. At CNCRUSH, a China-based CNC machining service provider with over 12 years of expertise, we are dedicated to delivering high-quality CNC Milled parts, CNC Turned parts, and comprehensive machining solutions, which are integral to optimizing performance in various industries.

Computer Numerical Control (CNC) machining has become an indispensable element in today’s manufacturing processes, offering not only enhanced efficiency but also reduced errors, waste, and manual labor. This article delves deep into the impact of CNC machining on manufacturing efficiency, examining how CNC machining influences automotive, machine building, and automation industries. Additionally, we highlight how CNCRUSH’s CNC machining services have helped businesses meet high-precision demands while ensuring cost-effectiveness.

This exploration will use information gathered from various resources discussing CNC machining’s transformative effects. The content below is organized into multiple subtopics, each providing a focused look at different aspects of CNC machining’s influence.

CNC Machining Service: A Revolution in Manufacturing Efficiency

At the core of CNC machining lies its ability to execute complex tasks with unparalleled precision and efficiency. Unlike traditional machining, CNC technology eliminates the potential for human error by automating the production process, thereby significantly improving production speed and consistency. CNC machining services are integral to industries requiring high levels of precision, such as automotive, medical devices, and aerospace.

- Automation and Reduced Labor: CNC machines can operate autonomously, which frees up labor to focus on more strategic tasks. The automation of machining services reduces errors, making CNC machines a cornerstone of the automation industry.

- Scalability: CNC machining makes scaling operations seamless, whether you’re producing one-off prototypes or large production runs.

- Precision and Repeatability: Every CNC-manufactured part, from CNC Milled parts to CNC Turned parts, offers repeatability with near-zero deviation, critical for high-precision components in automotive and machine building industries.

CNC Milled Parts: Redefining Accuracy and Speed in Manufacturing

CNC Milled parts play a pivotal role in various manufacturing sectors, offering solutions for creating intricate and accurate parts. Milled parts benefit from CNC’s ability to process a wide array of materials like metals, plastics, and composites. With tools programmed to follow exact digital blueprints, CNC milling achieves levels of detail that manual machining simply cannot replicate.

- Complex Geometries: CNC milling allows for the creation of parts with complex shapes, which is essential in automotive design and industrial automation.

- Material Versatility: CNC milling machines can work with different materials, including aluminum, steel, brass, and plastics, ensuring flexibility across industries.

CNC Turned Parts: Enhancing Efficiency in Production Lines

Turning is another CNC machining process that excels in the production of cylindrical parts such as shafts, bushings, and couplings, commonly used in industries like automotive and machine building. CNC Turned parts are manufactured with exceptional precision, contributing to smoother operations in high-stress environments such as automotive engines or industrial automation systems.

- Precision in Symmetry: CNC turning offers superior accuracy for round parts, which is essential in areas where balance and durability are critical.

- Time Efficiency: CNC turning machines can produce parts faster, contributing to a higher production rate without compromising quality.

The Role of CNC Machining in the Automotive Industry

The automotive industry relies heavily on CNC machining to manufacture high-performance parts with extreme precision. From engine components to gear mechanisms, CNC technology allows automakers to maintain strict quality standards while boosting production efficiency.

- Performance and Reliability: CNC Manufacturing enables the production of car parts with tight tolerances, which directly influences the vehicle’s performance, safety, and longevity.

- Customization: CNC machines provide the flexibility to produce customized parts, a growing trend in the automotive sector as consumers demand tailored solutions.

Automation and CNC Machining: Driving the Future of Industry 4.0

In the era of Industry 4.0, the integration of CNC Manufacturing with automation technologies has become a driving force behind smart factories. This synergy allows manufacturers to streamline workflows, automate repetitive tasks, and minimize downtime, all while maximizing output and quality.

- IoT and Machine Learning: Many CNC machines are now integrated with IoT (Internet of Things) and machine learning capabilities, enabling predictive maintenance and real-time monitoring.

- Reduced Downtime: Automation and CNC Manufacturing work together to reduce machine downtime, ensuring continuous operation in critical manufacturing sectors like automotive and aerospace.

Sustainability and CNC Machining: Reducing Waste, Enhancing Efficiency

Sustainability has become a top priority in manufacturing, and CNC Manufacturing plays a significant role in reducing material waste through efficient processes. At CNCRUSH, our CNC Manufacturing services are designed to minimize scrap and optimize material usage.

- Material Utilization: CNC machines are programmed to use materials more efficiently, resulting in less waste, which is beneficial both economically and environmentally.

- Energy Efficiency: Modern CNC machines are also more energy-efficient, reducing the overall carbon footprint of the manufacturing process.

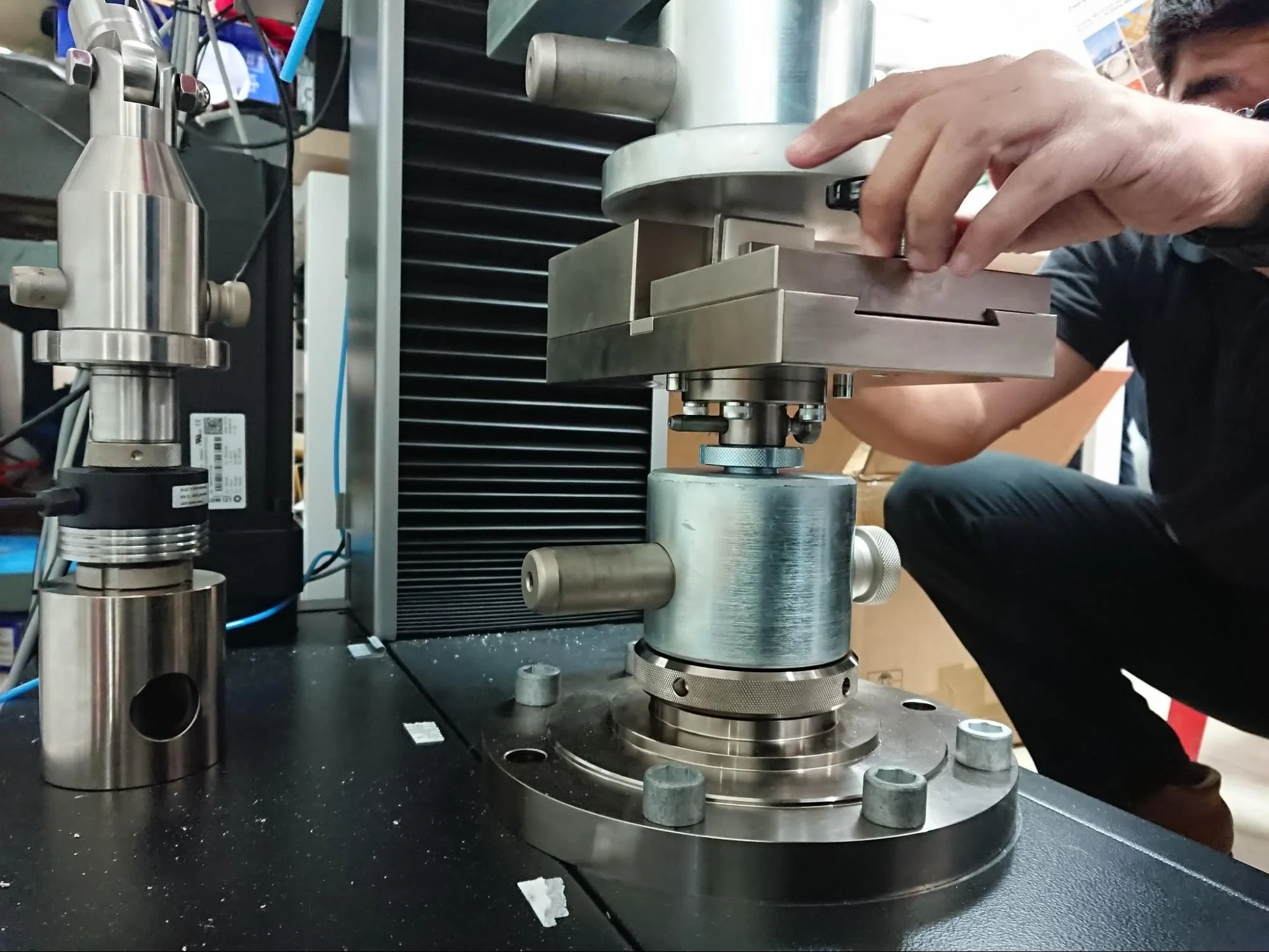

CNC Machining and Quality Control: Consistency in Production

Quality control is an inherent part of CNC Manufacturing services. Every part produced is consistent with the original design, ensuring that clients receive components that meet exact specifications every time.

- Tight Tolerances: The ability to meet strict tolerances is vital for industries like aerospace and medical devices, where even the slightest deviation can lead to failure.

- Inspection Systems: CNC machines often incorporate automated inspection systems, which provide real-time feedback and ensure that each part meets the required quality standards.

Cost-Effectiveness of CNC Machining Services

Although CNC machines require a high initial investment, their long-term cost benefits outweigh traditional methods. By minimizing errors and optimizing material use, CNC Manufacturing services help reduce overall production costs.

- Labor Savings: CNC machines require minimal supervision, which reduces labor costs.

- Reduced Errors: The automation of processes eliminates many human errors, reducing costly mistakes and rework.

CNC Machining and Prototyping: From Concept to Reality

CNC Manufacturing excels in prototyping, enabling manufacturers to produce accurate models that can be tested before full-scale production. This reduces time to market and ensures that final products meet exact specifications.

- Rapid Prototyping: CNC technology allows for quick production of prototype parts, enabling faster innovation cycles in industries like machine building and automotive.

- Design Validation: Prototypes produced via CNC Manufacturing provide essential feedback, allowing engineers to test designs before committing to production.

Flexibility of CNC Machining in Multiple Industries

One of the key advantages of CNC Manufacturing is its versatility. Whether in automotive, medical, or aerospace sectors, CNC technology can adapt to various applications, providing custom solutions to unique challenges.

- Cross-Industry Applications: From medical implants to automotive engines, CNC machining is pivotal across diverse industries, contributing to technological advancement.

- Custom CNC Solutions: CNCRUSH offers customized CNC machining solutions that are tailored to meet the unique requirements of each client.

Tables for Analysis

| Advantages of CNC Machining | Description |

|---|---|

| Automation | Reduced human error, increased productivity. |

| Precision | Tight tolerances, suitable for high-tech industries. |

| Flexibility | Works with multiple materials, adaptable to different applications. |

| Cost-effectiveness | Long-term cost savings due to optimized processes. |

| Key Industries | Primary Applications |

|---|---|

| Automotive | Engine parts, gear mechanisms, customization. |

| Aerospace | High-tolerance components, structural parts. |

| Medical Devices | Surgical instruments, implants, diagnostic equipment. |

FAQ Section

Q: What are CNC Milled parts used for?

A: CNC Milled parts are used in industries like automotive and aerospace to create components that require intricate designs and precise dimensions.

Q: How do CNC Turned parts differ from milled parts?

A: CNC Turned parts are primarily cylindrical in shape and are produced using a turning process, which is ideal for shafts and similar components, whereas milling is used for flat or complex-shaped parts.

Q: How does CNC Manufacturing improve manufacturing efficiency?

A: CNC machining reduces human error, increases production speed, ensures high precision, and minimizes waste, all of which lead to improved efficiency in manufacturing.

By incorporating these insights into our CNC machining services, CNCRUSH ensures that your business benefits from cutting-edge technology, whether you’re in automotive, machine building, or industrial automation. We invite you to explore our CNC solutions for CNC Milled parts and CNC Turned parts tailored to meet your specific needs. Visit CNCRUSH today for more information!