CNC machining has revolutionized numerous industries, but its impact on medical device manufacturing is particularly transformative. With precision, reliability, and adaptability at its core, CNC machining ensures that the stringent requirements of the medical sector are consistently met. In this article, we explore how CNC machining enhances precision in medical device manufacturing by analyzing industry insights, trends, and best practices. Additionally, we demonstrate why CNCRUSH, a trusted provider of CNC machining services with over 12 years of experience, is the ideal partner for your machining needs.

Summary of Key Insights

After analyzing authoritative sources on CNC machining for the medical industry, it’s clear that the technology’s ability to produce complex geometries with tight tolerances, combined with its versatility in handling various materials, positions it as a cornerstone in modern medical manufacturing. Below, we delve into ten comprehensive aspects of this transformative process.

1. The Critical Role of CNC Machining in Medical Device Manufacturing

In the medical device industry, precision is non-negotiable. Every device and component must meet stringent standards to ensure functionality, reliability, and safety. CNC machining excels in this arena by delivering parts with extremely tight tolerances and consistent quality. This precision is crucial for devices that come into direct contact with patients, such as surgical instruments, implants, and diagnostic tools. Furthermore, CNC machining minimizes the risk of defects, which is essential for maintaining patient trust and meeting regulatory requirements.

2. Enhancing Precision in CNC Milled Parts for Medical Devices

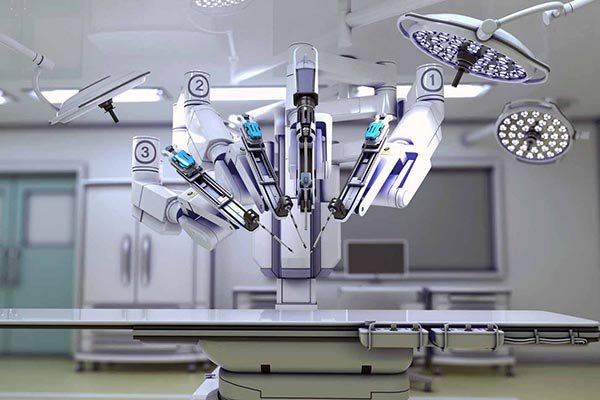

CNC milling is particularly suited for creating complex geometries required in medical devices. For example, components in imaging equipment or robotic surgical systems often have intricate designs that demand high accuracy. CNC milling ensures precise cuts, uniform finishes, and consistent dimensions, enabling medical devices to operate flawlessly. By utilizing advanced 3-, 4-, and 5-axis machines, CNC machining can handle even the most challenging designs with ease, enhancing the overall reliability of medical devices.

3. The Importance of CNC Turned Parts in Medical Equipment

CNC turning is indispensable for producing cylindrical and symmetrical parts. Applications include bone screws, catheters, and surgical handles, where roundness and smooth finishes are critical. These parts often interact directly with human tissue or must fit seamlessly with other components, making precision paramount. CNC turning ensures that every part adheres to exact specifications, reducing assembly issues and ensuring optimal performance in demanding environments.

4. Material Selection in CNC Machining for Medical Devices

The choice of material can significantly impact the performance and safety of medical devices. Biocompatibility is a primary consideration, especially for implants and surgical tools. Titanium, for instance, is lightweight, corrosion-resistant, and compatible with the human body, making it ideal for implants. Similarly, medical-grade plastics are often used for disposable instruments due to their affordability and sterilization capabilities. CNC machining can process these materials with remarkable precision, ensuring the finished product meets all functional and safety requirements.

5. Quality Assurance in CNC Machining Services

Quality assurance is a cornerstone of medical device manufacturing. At CNCRUSH, we implement rigorous inspection protocols using advanced equipment like CMMs (Coordinate Measuring Machines), hardness testers, and height gauges. Each component undergoes meticulous checks to ensure it meets the required dimensions, tolerances, and material properties. This process not only guarantees compliance with industry standards but also minimizes the risk of defects, ensuring reliable performance in critical applications.

6. Customization and Flexibility in CNC Machining

The medical industry often demands customized solutions to address unique patient or operational needs. CNC machining’s versatility allows manufacturers to create tailored components with minimal lead time. Whether it’s a prototype for a new surgical device or a modified design for an existing product, CNC machining can adapt to specific requirements without compromising on precision or efficiency. This capability is particularly valuable for personalized medical solutions like custom implants or patient-specific surgical guides.

7. Cost-Effectiveness and Efficiency in CNC Manufacturing

While the focus on precision is critical, cost considerations cannot be overlooked. CNC manufacturing optimizes material usage and reduces manual labor, making it an efficient production method. Automation in CNC processes further minimizes errors, lowering the overall cost of manufacturing. For large-scale production runs, the repeatability of CNC machining ensures consistent quality at competitive prices, making it a cost-effective choice for medical device manufacturers.

8. The Role of CNC Machining in Advancing Medical Technology

Innovations in medical technology often hinge on advancements in manufacturing techniques. CNC machining plays a pivotal role in developing cutting-edge devices, from minimally invasive surgical instruments to next-generation diagnostic tools. Its ability to produce highly complex and precise components supports the continuous evolution of medical technology, ultimately improving patient outcomes and healthcare delivery.

9. Partnering with a Reliable CNC Machining Service Provider

Selecting the right CNC manufacturing partner is crucial for the success of any medical device project. A reliable provider, like CNCRUSH, brings expertise, advanced equipment, and a commitment to quality. With over a decade of experience, we specialize in delivering precision CNC Milled and Turned Parts tailored to the unique needs of the medical industry. Our dedication to excellence ensures that clients receive components that meet or exceed their expectations.

10. Future Trends in CNC Manufacturing for Medical Devices

The future of CNC manufacturing in the medical sector is bright, driven by advancements in automation, robotics, and material science. Technologies like 3D printing integrated with CNC machining are opening new possibilities for prototyping and production. Additionally, the rise of smart machining systems promises even greater efficiency and precision. Staying at the forefront of these trends ensures that manufacturers can continue to meet the evolving demands of the medical industry.

FAQ Section: CNC Machining in Medical Device Manufacturing

Q1: Why is CNC machining preferred for medical devices?

A1: CNC machining ensures precision, repeatability, and the ability to work with biocompatible materials, meeting the stringent requirements of medical manufacturing.

Q2: How does CNC machining contribute to regulatory compliance?

A2: Detailed machining records and advanced inspection systems ensure adherence to standards such as ISO 13485 and FDA requirements.

Q3: Can CNC machining handle complex geometries for medical devices?

A3: Yes, CNC machining excels at creating intricate designs, essential for advanced medical devices.

Conclusion: Why Choose CNCRUSH for Medical CNC Machining

For over 12 years, CNCRUSH has delivered high-quality CNC manufacturing services to global clients. Located in China, we specialize in producing CNC milled parts and CNC turned parts, tailored to meet the exacting demands of the medical sector. With a focus on precision, compliance, and customer satisfaction, we are your trusted partner for CNC manufacturing services.

Visit CNCRUSH today to learn more about how we can support your medical device manufacturing needs.