CNC Machining has revolutionized manufacturing, enabling unparalleled precision and scalability. As industries like automotive, machine building, and automation demand increasingly complex components, efficient CNC machining practices are critical for maintaining competitiveness. For businesses seeking high-quality CNC Milled parts and CNC Turned parts, expertise and strategic optimization can significantly reduce costs while improving output.

At CNCRUSH, a leading China CNC factory specializing in CNC machining services for over 12 years, we focus on delivering precision CNC machining solutions to global clients. This article explores advanced strategies to enhance efficiency in CNC operations, supported by deep analysis, practical examples, and a commitment to empowering your manufacturing processes.

Summary of Insights from Industry Resources

Efficient CNC machining requires a harmonious blend of state-of-the-art technology, skilled craftsmanship, and robust workflows. Across sources, common themes emerge: optimization of programming, tooling selection, maintenance protocols, and workflow management. We’ll expand on these topics and tailor them to CNCRUSH’s proven expertise in delivering custom CNC solutions.

1. Optimize CNC Programming for Superior Performance

CNC programming lies at the heart of machining efficiency. Poorly optimized programs lead to machine idling, unnecessary tool changes, and suboptimal cycle times.

Best Practices:

- G-Code Refinement: Streamline code to minimize redundant operations.

- Simulations: Use CAM software to detect potential errors before production.

- Dynamic Toolpath Optimization: Advanced algorithms can reduce non-cutting moves and enhance feed rates.

At CNCRUSH, we utilize cutting-edge CAD/CAM software to ensure efficient CNC milling and turning processes, saving clients time and costs on large-scale projects.

2. Invest in High-Quality Tooling Systems

Tooling directly impacts machining speed, accuracy, and lifespan. Selecting the right tools for the job is crucial for producing CNC Milled parts and CNC Turned parts with precision.

Factors to Consider:

| Tool Type | Material Compatibility | Ideal Applications |

|---|---|---|

| Carbide Tools | Aluminum, Steel | High-speed machining |

| High-Speed Steel | Plastics, Soft Metals | Prototyping |

| Ceramic Tools | Hardened Alloys | High-temperature work |

In the automotive and automation sectors, where tolerance requirements are stringent, we use specialized tooling to meet demanding specifications efficiently.

3. Prioritize Machine Maintenance

Routine maintenance ensures consistent performance and prevents costly breakdowns. Neglected CNC machines can lead to dimensional inaccuracies and production downtime.

Maintenance Checklist:

- Daily Inspections: Check coolant levels, spindle alignment, and tool condition.

- Preventive Measures: Lubricate moving parts and replace worn components.

- Monitoring Systems: Use IoT-enabled sensors to track real-time machine health.

CNCRUSH integrates predictive maintenance protocols into our production workflows, ensuring uninterrupted CNC machining services for clients worldwide.

4. Leverage Automation and IoT Technologies

Automation enhances productivity by reducing human intervention in repetitive tasks, while IoT technologies enable data-driven decisions.

Advantages:

- Robotic Arm Integration: Increases throughput in CNC milling and turning tasks.

- IoT Dashboards: Provide insights into machine utilization and efficiency.

- Automated Quality Control: Ensures consistent accuracy for critical parts.

For CNC machining aluminum and CNC machining steel, we implement robotic systems to optimize cycle times without compromising quality.

5. Use Advanced Materials for Durability and Precision

Material selection impacts machining efficiency, tool wear, and part quality. High-quality materials reduce rejects and machining errors.

Key Materials:

| Material | Application | Benefits |

|---|---|---|

| Aluminum | Aerospace, Automotive | Lightweight, easy to machine |

| Stainless Steel | Medical, Food Industry | Corrosion-resistant |

| Engineering Plastics | Electronics, Prototyping | Lightweight, versatile |

At CNCRUSH, we provide expertise in CNC plastic machining and metals, ensuring the perfect match for every client’s project.

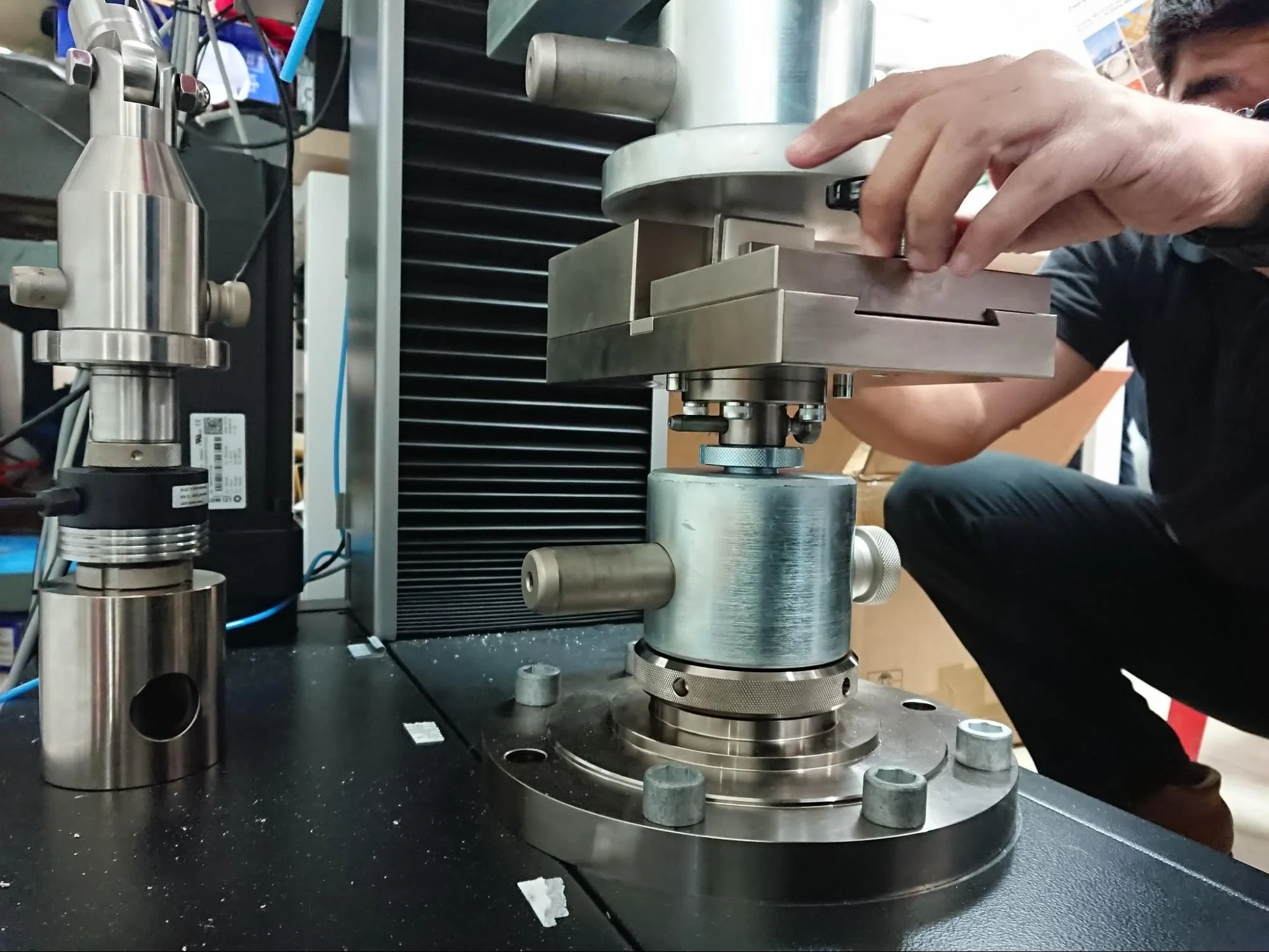

6. Optimize Workholding Techniques

Secure and stable workholding is essential to precision and repeatability in CNC machining. Improper workholding can lead to vibration, inaccuracies, and safety hazards.

Techniques:

- Vacuum Fixtures: Ideal for thin or delicate materials.

- Custom Jigs: Enhance repeatability for complex parts.

- Magnetic Chucks: Useful for flat ferrous workpieces.

By designing bespoke workholding solutions, CNCRUSH guarantees the production of tight-tolerance CNC Turned parts and other components.

7. Improve Shop Floor Workflow Management

Efficient workflows minimize idle time and streamline operations. Clear communication and defined processes are crucial in high-output CNC shops.

Strategies:

- Lean Manufacturing: Reduce waste and optimize resource use.

- Digital Job Scheduling: Real-time updates to prioritize urgent tasks.

- Cross-Training: Equip operators with diverse skills for greater flexibility.

CNCRUSH employs lean practices to enhance productivity across our operations, delivering cost-effective custom CNC solutions to clients globally.

8. Reduce Setup Times

Long setup times hinder productivity, especially in high-mix, low-volume production environments. Faster setups enable quicker transitions between jobs.

Methods:

- Quick-Change Tooling: Reduces downtime during tool swaps.

- Standardized Processes: Ensures consistency across operators.

- Pre-Staged Materials: Speeds up initial setups.

Our experience in CNC prototype machining has honed our ability to minimize setup times without sacrificing quality.

9. Enhance Operator Training and Expertise

Skilled operators are indispensable for leveraging advanced CNC capabilities. Continuous training ensures staff can handle complex projects with confidence.

Training Focus Areas:

- Machine Programming: Advanced G-code techniques.

- Tool Selection: Material-specific approaches.

- Problem-Solving: Addressing unexpected challenges in real-time.

By investing in workforce development, CNCRUSH remains a leader in precision CNC machining and complex component production.

10. Partner with a Trusted CNC Machining Service Provider

Outsourcing CNC machining to an expert provider like CNCRUSH can significantly boost efficiency while maintaining high quality.

Why Choose CNCRUSH:

- Expertise in Diverse Industries: Automotive, automation, and more.

- Global Reputation: Trusted by clients across Europe, the US, and Asia.

- Custom Solutions: Tailored approaches for CNC milling and turning.

FAQ: CNC Machining Efficiency

Q: What industries benefit most from CNC machining?

A: CNC machining is widely used in automotive, machine building, automation, aerospace, and medical industries.

Q: How does CNC machining differ for metals versus plastics?

A: Metals like aluminum and steel require robust tooling and higher speeds, while plastics benefit from careful heat management and precision cutting.

Q: Can outsourcing CNC machining reduce costs?

A: Yes, partnering with a specialized provider like CNCRUSH ensures high-quality results without the capital investment in equipment and training.

Conclusion: Elevate Your Manufacturing with CNCRUSH

In today’s competitive manufacturing landscape, maximizing CNC efficiency is essential for success. By implementing the strategies outlined above and partnering with an experienced provider like CNCRUSH, you can achieve unmatched precision, cost-effectiveness, and scalability. Whether you need CNC Milled parts, CNC Turned parts, or comprehensive CNC machining services, CNCRUSH is your trusted partner in China CNC manufacturing. Visit us today to explore how we can transform your production processes!