The aerospace industry demands precision, reliability, and innovation—qualities that align perfectly with CNC machining. From crafting lightweight titanium components to achieving complex geometries for cutting-edge designs, CNC machining has redefined how aerospace manufacturers meet stringent performance and safety standards. With over 12 years of expertise in CNC machining services, CNCRUSH, a trusted China CNC factory, specializes in CNC Milled parts and CNC Turned parts that power advancements in aerospace and defense.

In this article, we explore 10 transformative ways CNC machining is revolutionizing modern aerospace manufacturing, offering deep insights into its impact, challenges, and future potential. If you’re searching for reliable, high-precision solutions, CNCRUSH is your go-to partner for affordable and top-quality manufacturing services.

1. Precision Engineering: The Foundation of Aerospace Excellence

In aerospace manufacturing, every component must adhere to exact specifications to ensure safety and performance. CNC machining offers unparalleled precision, achieving tolerances as tight as ±0.001 inches. This level of accuracy is essential for parts that must endure extreme conditions, such as engine components and airframe structures.

How CNC Machining Achieves Precision:

- Advanced Software Integration: CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software ensure accurate programming and seamless execution.

- In-Process Monitoring: CNC machines utilize sensors and adaptive controls to maintain consistent quality.

Impact on Aerospace:

Precision reduces the risk of part failure, ensuring safety in critical applications like jet engines and flight control systems. At CNCRUSH, we’ve perfected our processes to deliver CNC Milled parts and CNC Turned parts that exceed aerospace standards.

2. Lightweight Materials: Driving Efficiency in Flight

Reducing aircraft weight is crucial for fuel efficiency and performance. CNC machining excels in working with lightweight materials like titanium, aluminum, and advanced composites, crafting parts that maintain strength while minimizing weight.

Key Material Benefits:

- Titanium: Combines high strength with low density, ideal for jet engines and landing gear.

- Aluminum: Lightweight and corrosion-resistant, commonly used in airframes.

- Composites: Enhanced flexibility and durability for critical aerospace applications.

Table 1: Popular Aerospace Materials Processed by CNC

| Material | Key Properties | Applications |

|---|---|---|

| Titanium | High strength-to-weight | Engines, Landing Gear |

| Aluminum | Lightweight, Corrosion-Resistant | Airframes, Fuselages |

| Composites | Durable, Flexible | Wing Structures, Interiors |

CNCRUSH specializes in machining these materials with precision, ensuring optimal performance for aerospace clients.

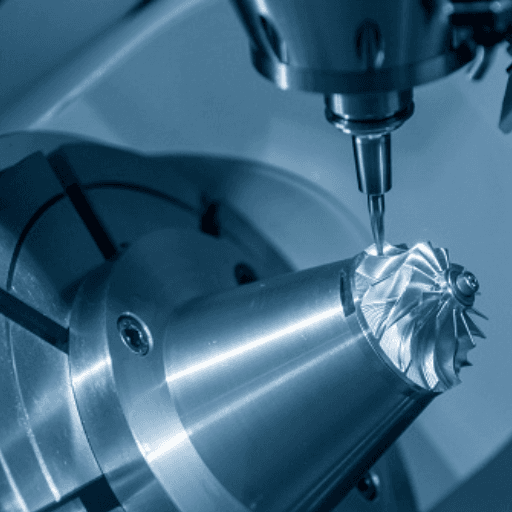

3. Complex Geometries: Unlocking Innovative Designs

Modern aerospace components often feature intricate shapes and internal structures that are impossible to achieve with traditional manufacturing methods. Multi-axis CNC machining enables manufacturers to create complex geometries, pushing the boundaries of innovation.

Applications of Complex Geometries:

- Aerodynamic Shapes: For optimized flight performance.

- Internal Channels: For cooling systems in jet engines.

At CNCRUSH, our advanced CNC equipment handles these challenges with ease, delivering intricate designs with flawless execution.

4. High Repeatability: Ensuring Consistency Across Parts

In aerospace, every component must perform as expected, with no room for variation. CNC machining ensures repeatability, producing identical parts consistently, even in large production runs.

Why Repeatability Matters:

- Safety: Ensures uniform performance of critical components.

- Cost Savings: Minimizes rework and defects.

Example:

For aerospace clients, CNCRUSH provides CNC Turned parts for landing systems, where consistent dimensions are essential for reliability and safety.

5. Shorter Lead Times with CNC Machining

Time is a critical factor in aerospace projects. CNC precision machining accelerates production timelines by automating processes and minimizing setup times. This capability is especially vital during prototyping and emergency part replacement.

CNCRUSH’s Role in Speed:

- Rapid Prototyping: Quick iterations of designs for testing and validation.

- Efficient Production: Optimized workflows to meet tight deadlines.

Table 2: CNC vs. Traditional Manufacturing Lead Times

| Process | Lead Time (Prototyping) | Lead Time (Production) |

|---|---|---|

| Traditional Machining | 3-6 weeks | 6-12 weeks |

| CNC Machining | 1-2 weeks | 4-8 weeks |

By choosing CNCRUSH, clients gain access to efficient CNC machining services tailored to their timelines.

6. Advanced Surface Finishing for Aerospace Standards

Surface finishing plays a critical role in aerospace manufacturing, impacting aerodynamics, corrosion resistance, and component longevity. CNC precision machining supports a variety of post-processing techniques, including polishing, anodizing, and coating.

Benefits of Advanced Finishes:

- Improved Aerodynamics: Smooth surfaces reduce drag.

- Enhanced Durability: Protective finishes prevent wear and corrosion.

At CNCRUSH, we provide comprehensive finishing options for CNC Milled parts and CNC Turned parts, ensuring they meet or exceed industry standards.

7. Cost-Effective Manufacturing with CNC

While the aerospace industry prioritizes quality and precision, cost efficiency remains a key consideration. Precision machining strikes a balance by reducing labor costs, minimizing waste, and streamlining production.

How CNC Machining Saves Costs:

- Automation: Reduces the need for skilled labor.

- Material Optimization: Minimizes waste through precision cutting.

Our Advantage:

CNCRUSH combines affordability with quality, offering cost-effective Precision machining services to aerospace manufacturers worldwide.

8. CNC Machining for Prototyping and Custom Parts

The aerospace industry thrives on innovation, and prototyping plays a pivotal role in testing new designs. CNC machining enables rapid production of prototypes, as well as custom parts for unique applications.

Prototyping Benefits:

- Quick Iterations: Allows for testing and refinement.

- High Fidelity: Prototypes match production quality for accurate evaluations.

CNCRUSH Expertise:

Our team specializes in prototyping and low-volume production, providing aerospace clients with custom CNC Milled parts and CNC Turned parts.

9. Supporting Industry 4.0 with Digital Integration

As aerospace manufacturing embraces Industry 4.0, CNC machining plays a central role. Integration with IoT (Internet of Things) and AI technologies enhances efficiency, monitoring, and predictive maintenance.

Digital Transformation in Aerospace:

- Real-Time Monitoring: Sensors track machine performance and detect issues early.

- Predictive Analytics: Reduces downtime through proactive maintenance.

CNCRUSH stays ahead of the curve by incorporating cutting-edge digital technologies into our CNC machining services.

10. Partnering with Trusted Suppliers for Global Success

Outsourcing to experienced CNC machining providers ensures aerospace companies meet their demanding requirements. With over 12 years of expertise, CNCRUSH has become a trusted partner for global aerospace manufacturers.

Why Choose CNCRUSH:

- Proven Expertise: Decades of experience delivering precision parts.

- Custom Solutions: Tailored CNC machining services for complex projects.

- Competitive Pricing: Affordable solutions without compromising quality.

FAQ: CNC Machining in Aerospace Manufacturing

1. What makes CNC machining ideal for aerospace manufacturing?

CNC machining offers precision, repeatability, and versatility, meeting the rigorous demands of the aerospace industry.

2. What materials does CNCRUSH handle for aerospace clients?

We specialize in machining titanium, aluminum, steel, and advanced composites, ensuring optimal performance for aerospace components.

3. Why should I choose CNCRUSH for CNC machining services?

CNCRUSH provides high-quality CNC Milled parts and CNC Turned parts, backed by 12 years of expertise and competitive pricing.

4. How does CNC machining reduce lead times for aerospace projects?

CNC machining automates processes and minimizes setup times, accelerating both prototyping and production phases.

At CNCRUSH, we are committed to delivering world-class CNC machining services that power aerospace innovation. Whether you need precision CNC Milled parts, reliable CNC Turned parts, or custom solutions, our team is here to help you succeed in the skies and beyond. Contact us today to learn more about how we can support your next aerospace project!