CNC Machining empowers aerospace parts with unmatched precision and reliability—CNCRUSH delivers unparalleled CNC machining service with expert CNC Milled parts and CNC Turned parts. CNCRUSH offers high-precision CNC machining services, processing aluminum, steel, and plastics. Trusted by global clients for over 12 years.

🚀 CNC Machining Power Boost: 9 Game-Changing Strategies for High-Precision Aerospace Parts

🔍 Summary of Key Industry Insights

CNC Machining in aerospace demands exceptional accuracy, consistently achieving tolerances within ±0.0001–±0.005inches (≈±0.002–0.127mm). It handles exotic materials—titanium, Inconel, aluminum alloys, composites—and intricate geometries via multi-axis systems. Regulatory demands like AS9100 and NADCAP require traceability, documentation, and quality excellence. Leading shops integrate automation, AI, robotics, and in-process monitoring to ensure repeatable results. The searcher intent is to discover aerospace-grade machining providers who deliver consistent precision, compliance, speed, and value.

Below are 9 deeply analyzed H2 sections, tables, and FAQs showing how CNCRUSH leverages these capabilities:

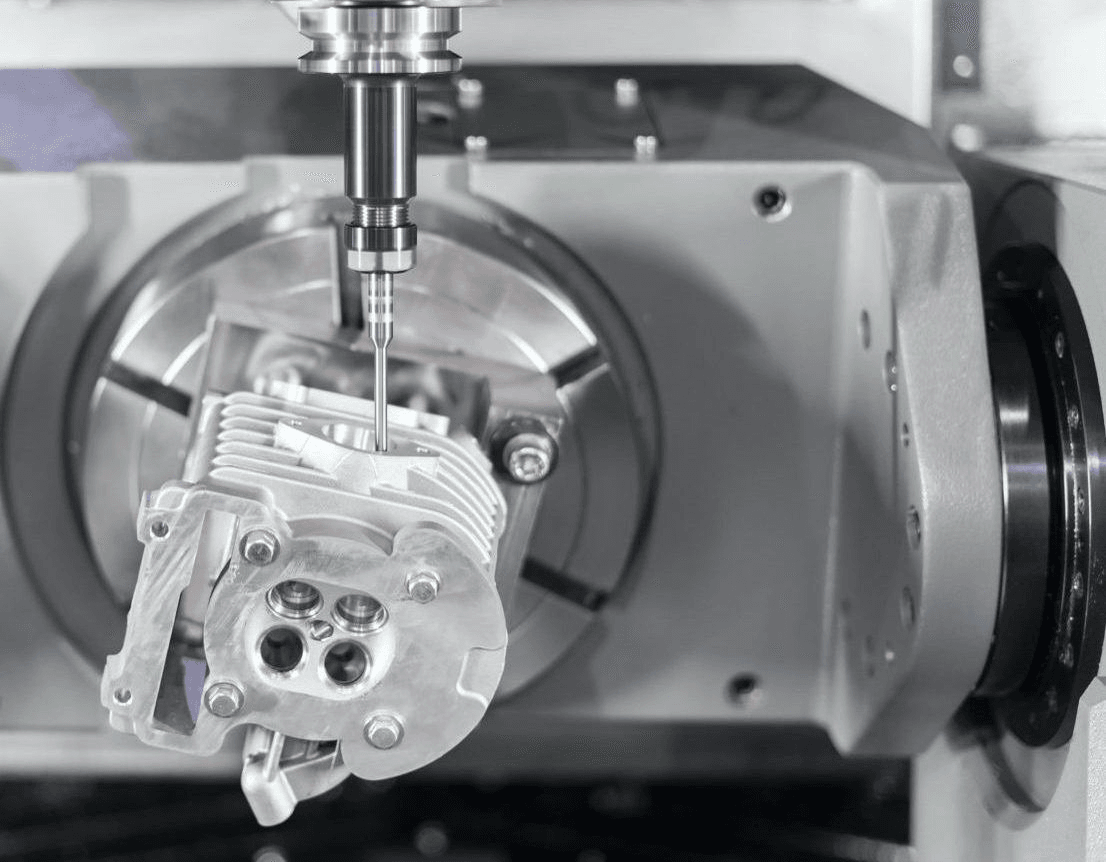

1. CNC Machining service: Achieving Micron-Level Tolerances

The aerospace sector requires tolerances from ±0.005″ to as tight as ±0.0001″ (≈±0.002mm). Achieving this ultra-tight precision demands climate-controlled machining cells, hardened components, and real-time in-process probing. At CNCRUSH, with 12 years of expertise, our CNC Machining service ensures micron-level repeatability using calibrated CMMs, thermal management, and SPC.

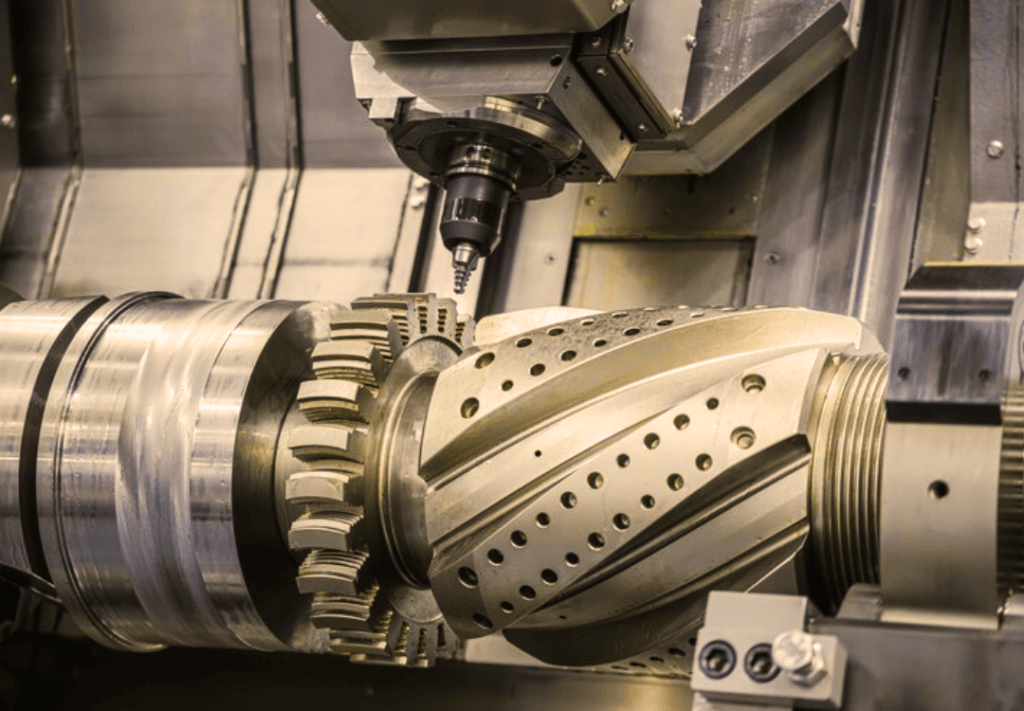

2. CNC Machining service: Working Exotic Materials under Demand

Aerospace parts often use titanium alloys, Inconel, PEEK, carbon composites, and aerospace-grade aluminum—materials notoriously difficult to machine. Our CNC Machining service includes optimized spindle speeds, specialized high-performance tooling, and advanced cooling strategies to handle these materials reliably in CNC Milled parts and CNC Turned parts, delivering both quality and aerodynamic soundness.

3. CNC Machining service – CNC Milled parts vs CNC Turned parts in Aerospace

- CNC Milled parts handle complex 3D geometries—airframe brackets, manifolds, housings.

- CNC Turned parts suit cylindrical components—shafts, bushings, fasteners.

CNCRUSH expertise evaluates design requirements and volume to recommend the optimal method—ensuring precision and cost-efficiency with every CNC Milled parts and CNC Turned parts order.

4. CNC Machining service: Multi-Axis Automation & Smart Machining

5-axis (and higher) CNC Machining integrated with robotics, AI-based monitoring, and vibration control significantly reduces cycle time and increases consistency. CNCRUSH marries advanced CNC Milled parts and CNC Turned parts processes with automated tool-change, adaptive control, and live data feedback—delivering scalable production with uncompromised performance.

5. CNC Machining service: Quality Systems for AS9100 & NADCAP Compliance

Quality management under AS9100 and NADCAP accreditation mandates strict documentation, traceability, and defect prevention. CNCRUSH maintains ISO 9001 / AS9100-grade quality systems, machine calibration logs, full lot traceability, and detailed inspection reports—ensuring every CNC Milled parts and CNC Turned parts batch is ready for audit and deployment.

6. CNC Machining service: Prototype-to-Production Scalability

Prototyping and short-run builds require agility, while mass production requires efficiency. CNCRUSH offers both, delivering prototype CNC Milled parts and CNC Turned parts in as little as 5–7 days, and transitioning seamlessly to automated, multishift production for hundreds or thousands of units while maintaining tight aerospace tolerances.

7. CNC Machining service: Design for Manufacturability (DFM) Expertise

Smart design choices reduce setups, minimize flips, and improve tolerance distribution. Our engineers review CAD/CAM designs to propose optimal features—such as combining features on common axes, recommending bar stock for CNC Turned parts, or adjusting wall thickness to reduce tool deflection—achieving cost, time, and quality balance for aerospace applications.

8. CNC Machining service: Precision Finishes & Special Processing

Surface finishes in aerospace require Ra < 8µin, sometimes as low as 0.25µin. CNCRUSH applies post-processes like anodizing, shot-peening, PVD coatings, and electropolishing. Our turnkey approach ensures every CNC Milled parts and CNC Turned parts batch is delivered not just dimensionally accurate, but also surface-ready and compliant for aerospace assembly.

9. CNC Machining service: Inspection, Traceability & Documentation

Every aerospace batch undergoes 100% inspection using CMM, laser scanning, and optical profilometry—linked to full SPC log and FAI reports. CNCRUSH assigns part IDs and maintains traceable documentation per serial number. Digital records and backup systems ensure that every CNC Milled parts and CNC Turned parts delivery is fully traceable and compliant.

📊 Table 1: Material & Machining Challenges in Aerospace

| Material | Key Properties | Machining Challenges | Typical Aerospace Use |

|---|---|---|---|

| Aluminum 7075 | High strength-to-weight | Prone to galling, needs coolant | Wing spars, structural brackets |

| Titanium Ti‑6Al‑4V | Heat-resistant, lightweight | High tool wear, heat generation | Engine mounts, landing gear |

| Inconel 718 | High-temp, corrosion-resistant | Ultralow-speed cutting, tool wear | Turbine components, exhaust modules |

| Carbon Fiber Composite | Light, stiff | Dust, delamination risk | Fuselage panels, stabilizer assemblies |

| Stainless Steel | Durable, wear-resistant | Work-hardening tendency | Fasteners, valve bodies |

📊 Table 2: CNC Milled parts vs CNC Turned parts in Aerospace

| Feature | CNC Milled parts | CNC Turned parts |

|---|---|---|

| Geometry Complexity | Intricate slots, pockets, surfaces | Cylindrical shafts, bushings |

| Typical Tolerance | ±0.005in–±0.0005in | ±0.002in–±0.0001in |

| Material Yield | ~60–75% | ~80–90% (less waste) |

| Best for Prototype Speed | Moderate | Fast |

| Ideal for Volume Runs | Medium to high volume | High-volume production |

❓ FAQ – CNC Machining for Aerospace Parts

Q1: What certifications does CNCRUSH hold?

A: We operate on ISO9001 / AS9100-level systems, offer documentation per AS9100 and NADCAP traceability, and maintain full lot-based quality control.

Q2: Can you machine titanium and Inconel to aerospace standards?

A: Absolutely. Our CNC Machining service includes specialized tooling and process control to deliver aerospace-grade CNC Milled parts and CNC Turned parts in these difficult alloys.

Q3: What inspection data will I receive?

A: Every batch comes with CMM report, SPC chart, FAI report, and material certificates—all tied to specified part IDs.

Q4: How long is your lead time?

A: Prototype orders can ship in 5–7 business days; high-volume runs typically in 10–15 days. We scale efficiently without compromising quality.

Q5: Do you support automotive, machine building, and automotion?

A: Yes. Our cross-industry capabilities—including automotive and machine building—help drive process improvements that benefit aerospace parts.

💡 Why CNCRUSH is Your Ideal Aerospace CNC Machining Partner

- 12 years of proven CNC Machining service, blending aerospace-grade precision with global reliability

- Complete production ecosystem: CNC Milled parts, CNC Turned parts, coatings, inspection, and traceability

- Global standards compliance (AS9100, NADCAP-ready processes) with transparent, audit-ready documentation

- Emotional commitment: we take pride in contributing to safety, reliability, and excellence in every aerospace mission

- Cost-effective, automated, and scalable solutions—prototype to production without compromise

When aerospace engineers demand zero-defect manufacturing, they choose CNCRUSH. Visit our website to learn how our world-class CNC Machining service, expertise in CNC Milled parts and CNC Turned parts, elevated by experience across automotive, machine building, and automotion, can drive your next aerospace breakthrough.