CNC Machining: A Masterpiece of Modern Engineering

CNC machining (Computer Numerical Control machining) has become a fundamental process in modern manufacturing, offering unparalleled precision and efficiency. Industries such as automotive, machine building, and automation rely on this technology to produce high-quality components with complex geometries.

For over 12 years, CNCRUSH has been at the forefront of CNC machining services, providing CNC Milled parts and CNC Turned parts to global clients. This comprehensive guide explores 10 essential CNC machining techniques, helping you unlock the potential of this advanced manufacturing process. Whether you need a single prototype or high-volume production, mastering these techniques is crucial for achieving top-tier results.

1. What is CNC Machining? A Gateway to Precision

CNC machining is a highly automated process where a computer controls machine tools to create parts from raw materials like metal or plastic. Unlike manual machining, which requires direct human intervention, CNC machining uses pre-programmed software to execute complex designs with absolute precision.

How CNC Machining Works

- Design Creation: The process begins with CAD (Computer-Aided Design) software to create the part’s blueprint.

- Code Generation: CAM (Computer-Aided Manufacturing) software translates the CAD design into machine-readable G-code.

- Machining Execution: The CNC machine interprets the G-code, guiding tools to cut, drill, or mill the raw material.

Advantages of CNC Machining

- Unmatched Precision: Achieves tolerances within microns, making it ideal for industries with stringent quality requirements, such as aerospace and medical devices.

- Material Versatility: Handles a variety of materials, including aluminum, steel, brass, and plastics.

- Scalability: Efficiently produces everything from prototypes to large-scale production runs.

CNCRUSH’s Expertise

As a CNC manufacturing services provider, CNCRUSH has delivered high-quality CNC machining services for over a decade, focusing on CNC Milled parts and CNC Turned parts for critical applications.

2. The Role of CNC Milling in Producing Complex Geometries

CNC Milling is one of the most versatile CNC machining techniques. It employs a rotating cutting tool to remove material from a workpiece, enabling the creation of intricate designs and fine details. Industries such as electronics, aerospace, and automotive rely heavily on CNC Milling for their custom components.

Key Features of CNC Milling

- Multi-Axis Control: CNC Milling machines come in 3, 4, and 5-axis configurations, allowing for more complex cuts and shapes.

- Precision and Surface Quality: Achieves smooth finishes and intricate details, reducing the need for additional processing.

- Customizability: Ideal for producing prototypes or small-batch custom parts.

| CNC Milling Configurations | Capabilities |

|---|---|

| 3-Axis | Handles simple geometries and planar surfaces. |

| 4-Axis | Adds rotational flexibility for curved or angled cuts. |

| 5-Axis | Enables complex geometries, such as aerospace parts. |

Pro Tip from CNCRUSH

Leverage CNCRUSH’s expertise in custom CNC solutions to access the precision and flexibility of CNC Milling for your project.

3. CNC Turning for High-Speed Production of Cylindrical Parts

CNC Turning specializes in machining cylindrical components, using a rotating workpiece and stationary tools to cut shapes, threads, or grooves. It is particularly effective for producing CNC Turned parts used in automotive, automation, and machine-building applications.

Key Characteristics of CNC Turning

- Speed and Efficiency: Ideal for high-volume production of shafts, bushings, and other cylindrical parts.

- Complex Threading: Creates both internal and external threads with precision.

- Material Versatility: Works effectively with metals like steel, brass, and aluminum, as well as plastics.

| Advantages of CNC Turning | Why It Matters |

|---|---|

| High Accuracy | Ensures dimensional consistency for tight fits. |

| Efficient Production | Reduces cycle times for large batches. |

| Cost-Effective | Minimizes waste by optimizing material usage. |

CNCRUSH’s Specialty

With 12 years of expertise, CNCRUSH provides precision CNC Turned parts, ensuring durability and accuracy for critical applications.

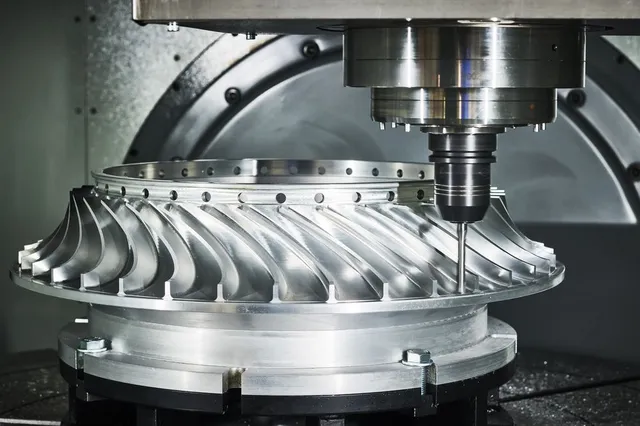

4. 5-Axis Machining: Breaking Barriers in Complexity

5-axis CNC machining represents the pinnacle of manufacturing flexibility, allowing simultaneous movement along five axes. This capability makes it the go-to method for producing parts with intricate geometries and tight tolerances.

Benefits of 5-Axis Machining

- Enhanced Precision: Handles complex surfaces, such as turbine blades or medical implants, with unmatched accuracy.

- Reduced Setup Time: Eliminates the need for multiple setups, saving time and resources.

- Improved Surface Quality: Delivers smooth finishes, reducing or eliminating post-processing.

Applications in Key Industries

- Aerospace: Complex structural components.

- Medical: Custom implants and surgical tools.

- Automotive: Advanced drivetrain and engine components.

Why CNCRUSH?

As a trusted CNC machining in China provider, CNCRUSH combines 5-axis expertise with a commitment to affordability, offering clients world-class precision at competitive rates.

5. Material Considerations for CNC Machining: Choosing the Right Fit

The choice of material significantly impacts the performance, cost, and feasibility of CNC machining projects. Factors such as strength, weight, corrosion resistance, and machinability play a crucial role.

Common Materials for CNC Machining

- Aluminum: Lightweight, corrosion-resistant, and easy to machine.

- Steel: Offers exceptional strength and durability for heavy-duty applications.

- Brass: Combines excellent machinability with aesthetic appeal.

- Plastics: Versatile, lightweight, and ideal for insulation or low-weight needs.

Material Selection at CNCRUSH

Our team helps clients choose materials that align with their project’s performance and budget requirements, whether it’s CNC machining aluminum for lightweight parts or CNC plastic machining for prototyping.

6. High-Speed Machining (HSM): Accelerating Productivity

High-Speed Machining is a cutting-edge approach that focuses on faster cutting speeds and optimized tool paths. This technique enhances productivity while maintaining exceptional precision, making it ideal for time-sensitive projects.

Advantages of HSM

- Faster Cycle Times: Achieves higher throughput without compromising quality.

- Longer Tool Life: Reduces tool wear through optimized cutting parameters.

- Superior Surface Finish: Delivers parts with minimal need for post-processing.

7. CNC Prototyping: Innovate with Precision

Rapid prototyping is a critical phase in product development, allowing designers to test and refine ideas before full-scale production. CNC machining offers unmatched accuracy and material options for prototyping.

Why Choose CNC for Prototyping?

- High Fidelity: Creates prototypes that closely mimic final products.

- Wide Material Range: Accommodates metals, plastics, and composites.

- Quick Turnaround: Enables fast iterations for design improvements.

8. Importance of Quality Control in CNC Machining

Quality control is a cornerstone of high-quality CNC machining. Rigorous checks ensure that every part meets the required specifications, guaranteeing reliability and performance.

QC Techniques at CNCRUSH

- Coordinate Measuring Machines (CMMs): Measure dimensions with micrometer accuracy.

- Material Certifications: Verify material properties for compliance with industry standards.

9. CNC Machining for Metal Fabrication

CNC machining plays a vital role in metal fabrication, transforming raw sheets or blocks into precision parts. From CNC machining aluminum for lightweight structures to steel for durable components, CNC methods ensure reliability across applications.

10. Cost-Efficient CNC Solutions: Balancing Quality and Budget

While precision machining can be cost-intensive, working with an experienced manufacturer like CNCRUSH ensures the best balance between quality and affordability.

Why CNCRUSH?

- Competitive Pricing: Leverages economies of scale as a China CNC factory.

- Custom Solutions: Tailors machining strategies to client needs.

- Global Trust: Over a decade of experience serving international clients.

FAQ: CNC Machining Services

Q: What materials are compatible with CNC machining?

A: CNC machining works with a range of materials, including aluminum, steel, brass, and plastics.

Q: How does CNC machining ensure precision?

A: By using advanced software and automated tools, CNC machining achieves tolerances as tight as ±0.001 inches.

Q: Why choose CNCRUSH for your CNC machining needs?

A: With 12 years of expertise, CNCRUSH delivers top-quality CNC Milled parts, CNC Turned parts, and custom solutions at competitive prices.

Conclusion

From CNC Milling to 5-axis machining, these advanced techniques offer the precision and flexibility needed for modern manufacturing. With over a decade of expertise, CNCRUSH is your trusted partner for all your CNC machining services needs. Contact us today for a free consultation.