CNC machining tolerances are pivotal in achieving high-quality, functional parts essential for industries like automotive, machine building, and automation. As a top-tier provider, CNCRUSH brings over 12 years of expertise to meet complex tolerance requirements with precision and cost-effectiveness. This article explores the standards, considerations, and strategies in CNC tolerancing to help designers and manufacturers optimize their projects.

What is Precision in CNC Machining?

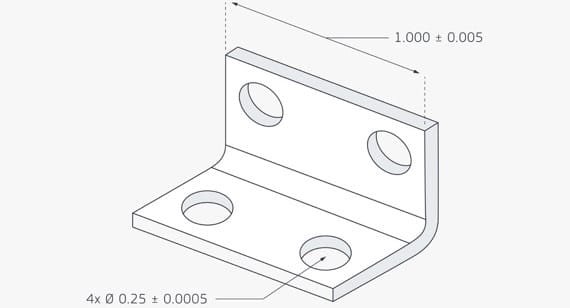

Precision Parts are core to the CNC machining process, defining the allowable range for deviation in part dimensions. In manufacturing, this is often measured in tolerances, like ±0.005 inches or tighter for highly specific applications. Tighter tolerances ensure better fit and function, especially in assemblies where parts must interact flawlessly, such as in automotive and automation applications.

Types of CNC Machining Tolerances and Their Uses

Understanding the types of tolerances is crucial to select the right one for specific parts.

- Standard Tolerances: Standard tolerance of ±0.005 inches or ±0.13mm is common for general applications.

- Limit Tolerances: Defined as a range rather than a deviation, used for precision parts in automation.

- Bilateral and Unilateral Tolerances: Bilateral allows deviation on both sides, unilateral on only one, ideal for parts needing exact fits.

- Geometric Dimensioning & Tolerancing (GD&T): Specifies form and feature alignment, critical for automotive and complex assemblies.

Benefits of Selecting the Right Tolerances for CNC Machining Services

Selecting optimal tolerances is fundamental for efficient CNC machining services, impacting cost, lead time, and functionality.

- Cost Efficiency: Tighter tolerances often require more labor and time. Standard tolerances are more cost-effective for parts that don’t require exacting precision.

- Assembly Integrity: Precision Parts with the correct tolerances reduce risks of assembly issues, especially for CNC Milled parts and CNC Turned parts.

- Material Efficiency: Overly strict tolerances may waste material, while looser tolerances may compromise functionality.

Table: Standard Tolerances Across CNC Machining Types

| Machining Process | Tolerance (inches) | Tolerance (mm) | Application |

|---|---|---|---|

| CNC Milling (3-axis) | ±0.005 | ±0.13 | General use |

| CNC Turning | ±0.005 | ±0.13 | High precision |

| 5-Axis CNC Milling | ±0.005 | ±0.13 | Complex shapes |

| Grinding | ±0.001 | ±0.025 | Ultra-fine finishes |

Factors Affecting CNC Machining Tolerances

- Material Choice: Softer materials can distort easily, while harder ones like steel hold tighter tolerances but require careful machining.

- Surface Finish: Finishes like anodizing or powder coating may slightly alter part dimensions.

- Cutting Tool Quality: High-quality tools are essential to maintaining Precision Parts.

- Machine Type and Condition: Advanced CNC machines can achieve tighter tolerances, especially multi-axis models used for intricate CNC Turned parts.

Material Considerations for CNC Machined Precision Parts

Material properties significantly impact achievable tolerances:

- Metals: Steel and aluminum are common, with good stability for tight tolerances.

- Plastics: Tend to expand and contract, needing looser tolerances.

- Composites: Require a balance of tolerance and material-specific considerations.

The Cost of Tighter CNC Machining Tolerances

Tighter tolerances result in higher costs due to extended machining time, tool wear, and potential material wastage. By understanding the application, manufacturers can determine if a standard tolerance is acceptable or if precision is required.

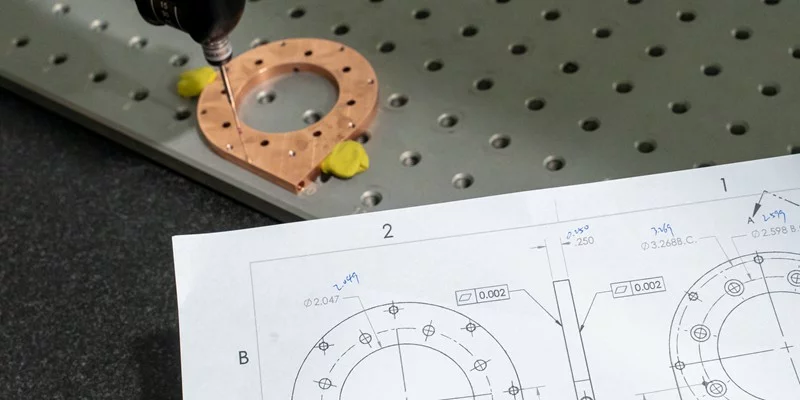

Ensuring Quality with CNC Machining Tolerances

Ensuring parts meet tolerance requirements often involves quality assurance measures such as:

- Dimensional Inspection: Using tools like calipers, micrometers, and CMM machines.

- GD&T Analysis: Specifying orientation, position, and profile can help ensure functionality and reduce assembly failures.

- Tool Alignment Checks: Essential for maintaining precision throughout production.

When and Where to Use Precision Parts with Tight Tolerances

Precision Parts with tight tolerances are particularly useful in:

- Automotive: Ensuring assembly fit in engine components.

- Machine Building: Guaranteeing consistent operation in automated systems.

- Automation: Components in robotic assemblies that require exact movements.

Tips for Choosing the Right Tolerances

- Identify Critical Parts: Focus tolerances on essential features, such as joints in CNC Turned parts.

- Consult with Experts: At CNCRUSH, we help clients determine necessary tolerances.

- Balance Cost and Function: Only select strict tolerances where functional, cost-effective, and crucial for part success.

FAQ: CNC Machining Tolerances for Precision Parts

- What is considered a tight tolerance in CNC machining? Tight tolerances typically range around ±0.001 inches. They are vital for parts requiring strict alignment, like gears in automation.

- How do materials affect CNC tolerances? Softer materials are harder to machine to tight tolerances, while metals like steel and aluminum can achieve closer precision.

- When is GD&T necessary? For Precision Parts requiring specific orientation and positioning, GD&T tolerances ensure accuracy beyond simple dimension limits.

- Why are tolerances important in automotive parts? Precision Parts tolerances ensure that each part integrates seamlessly into complex assemblies, reducing wear and improving reliability.

Why Choose CNCRUSH for Your CNC Machining Service?

With 12+ years of experience and expertise, CNCRUSH offers reliable CNC machining services, specializing in CNC Milled parts and CNC Turned parts tailored to the automotive, machine building, and automation sectors. Located in China, our advanced technology ensures we meet international standards for accuracy and efficiency, delivering high-quality custom CNC solutions.

Conclusion

Selecting the correct CNC machining tolerance is fundamental to producing high-quality, functional parts. The right tolerance improves fit, reduces costs, and guarantees consistency. At CNCRUSH, our team ensures that each project meets rigorous precision standards, serving global industries with expertise and cutting-edge technology. Visit CNCRUSH for professional CNC machining services tailored to your project needs.

Sehr geehrte Damen und Herren,

wir hätte mal eine Anfrage in Bezug auf die Stifte, die Sie in den Bildern sehen können. Hätten Sie die Möglichkeit diese zu Richten (Entgraten) oder einfach neu herzustellen?

Der Jahresbedarf würde zwischen 500 bis 1.000 Stück sein.

Danke

i.A. Andreas Reichle

Purchasing

Hi Andreas, thanks for asking. Could you please send details to my email box, in**@*****sh.com.